Company News

15 2025-10

15 2025-10 Metal cutting process inventory, which method of machining is more applicable?

In the field of machining, metal cutting is the most basic and most commonly used to a process, metal cutting processing is divided into many kinds, there are turning, drilling, boring, planing, broaching, milling and grinding.

15 2025-08

15 2025-08 What is plunge milling? What are its applications in machining?

In the field of mechanical machining, milling is a common metal cutting method, and plunge milling, as a special milling process, is increasingly gaining attention in high-efficiency machining. So, what exactly is plunge milling? What are its unique applications and advantages in machining?

17 2025-07

17 2025-07 What are the advantages of milling cutters in the machining of wind instrument fittings?

The sound and texture of a wind instrument depend largely on the processing accuracy and details of the fittings. In many processing tools, milling cutter compared to other tools such as lathe, drill, file, etc., its unique structure and processing characteristics, can be better adapted to the complex shape of the fittings and precision requirements, and become the key to improve the processing quality and efficiency.

25 2025-04

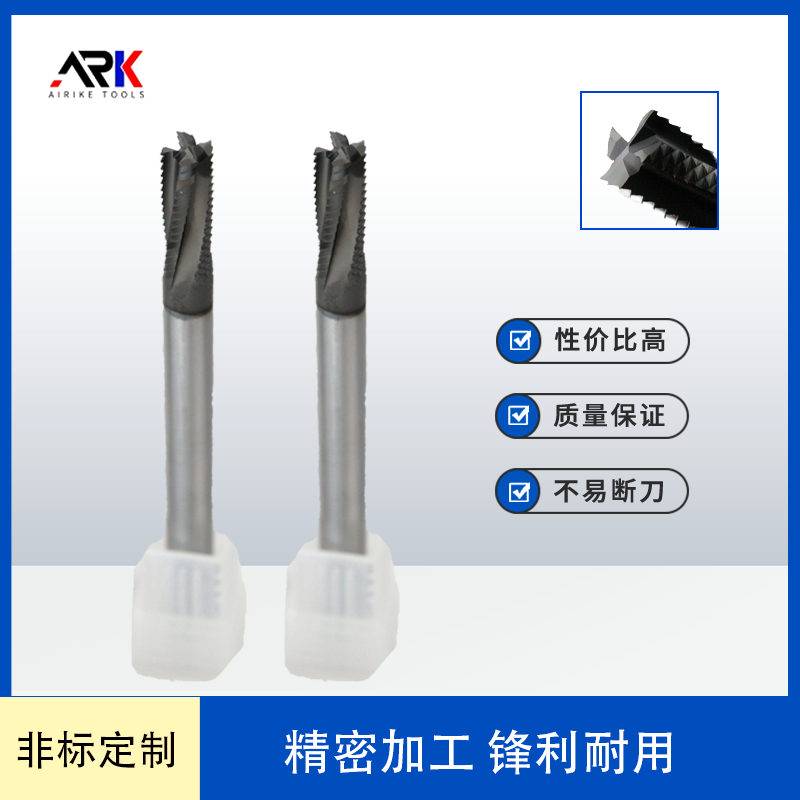

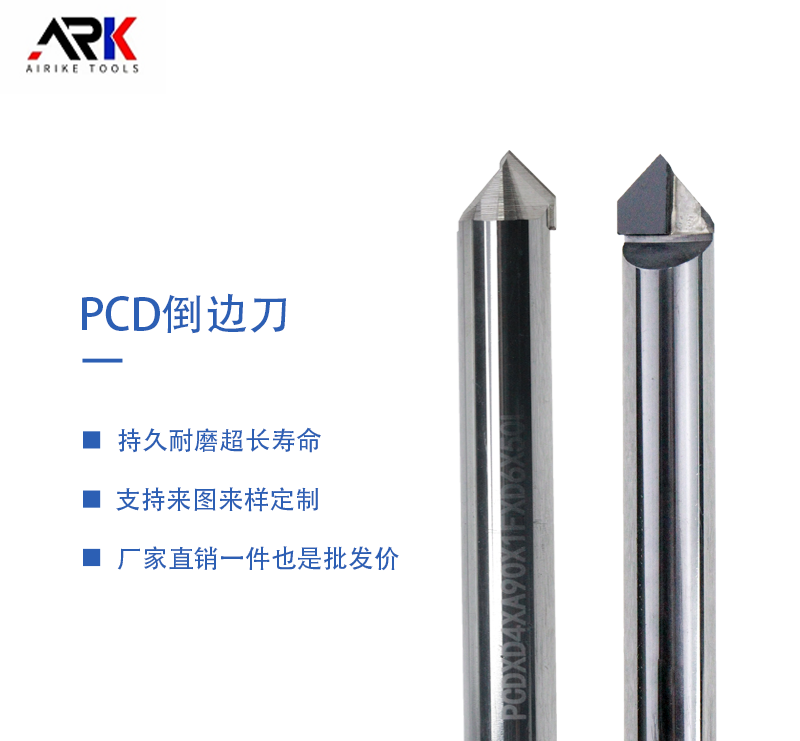

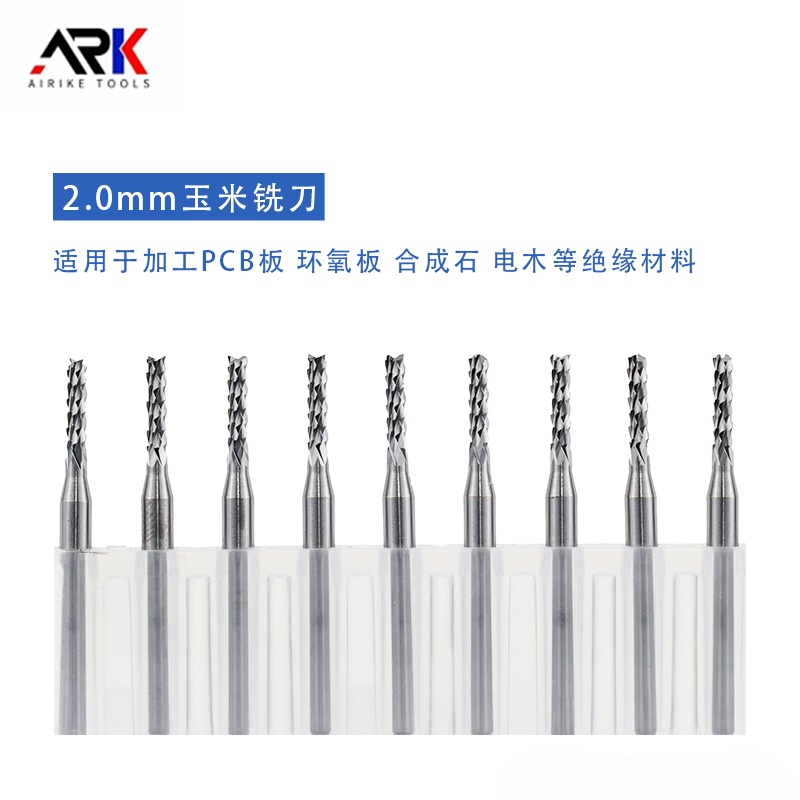

25 2025-04 What are the uses of several common milling cutters?

Milling cutters are a type of tool with many types and wide applications in wood cutting processing. They are widely used in various machine tools for milling work, flat milling or forming milling of straight or curved workpieces, milling of various tenons of integral milling cutters, opening tenons, drilling holes, processing tongues or cuts, copying carving, etc. So what are the uses of several common milling cutters?