Email Us

Woodworking Milling Cutter

Zhongyeda's high-quality woodworking milling cutter, as an important cutting tool in woodworking machinery, is an indispensable key component in the wood processing industry. With its efficient and precise cutting performance, as well as its wide applicability and durability, it plays a vital role in many fields such as furniture manufacturing, wooden door production, wooden window manufacturing, and wooden craft carving. Below, we will introduce the characteristics, types, applications and advantages of woodworking milling cutters in detail.

Our woodworking milling cutters are usually made of high-quality carbide or high-speed steel materials, which have extremely high hardness and wear resistance, and can ensure that the cutter remains sharp during long-term, high-intensity cutting, reduce wear and extend service life. In addition, the design of woodworking milling cutters focuses on cutting efficiency and processing accuracy. Its unique edge shape and chip groove design help to quickly discharge wood chips during cutting, avoid clogging, and keep the cutting surface smooth and flat.

There are many types of woodworking milling cutters. According to different cutting shapes and application scenarios, they can be divided into straight edge milling cutters, ball head milling cutters, dovetail groove milling cutters, T-slot milling cutters, wave grain milling cutters and other types. Straight-edge milling cutters are mainly used for cutting planes, grooves and edges; ball-end milling cutters are suitable for processing three-dimensional surfaces and complex shapes; dovetail milling cutters and T-slot milling cutters are specifically used for processing slots of specific shapes; and wave-pattern milling cutters can create a unique wave texture effect.

- View as

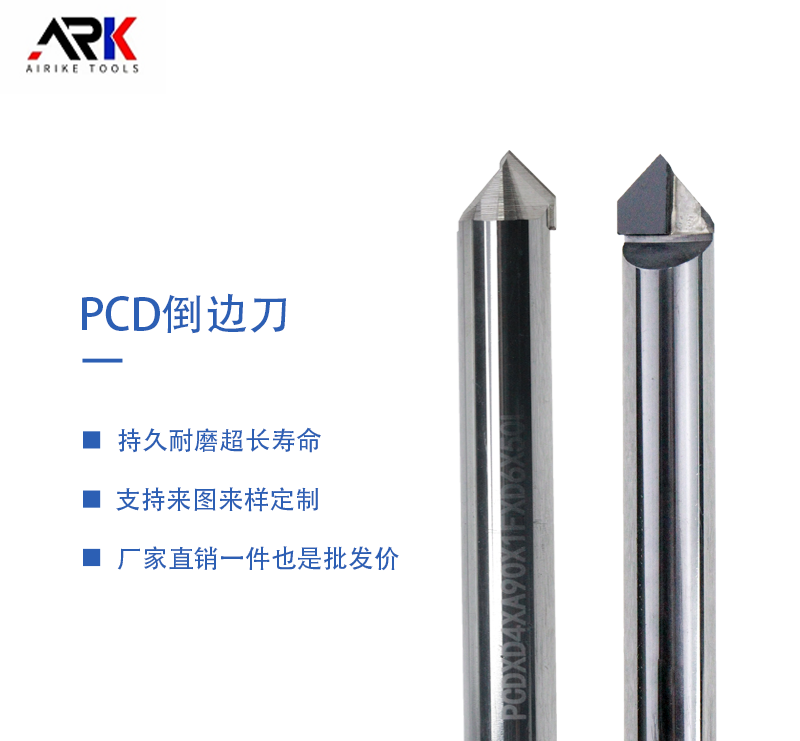

PCD Chamfering Cutter

Triple Edge Wood Splitting Knife

10° Taper Ball Cutter

TCT double-flute left-handed milling cutter

Welded milling cutter

Three-Blade Woodworking Rough Milling Cutter

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.