Stone Carving Milling Cutter

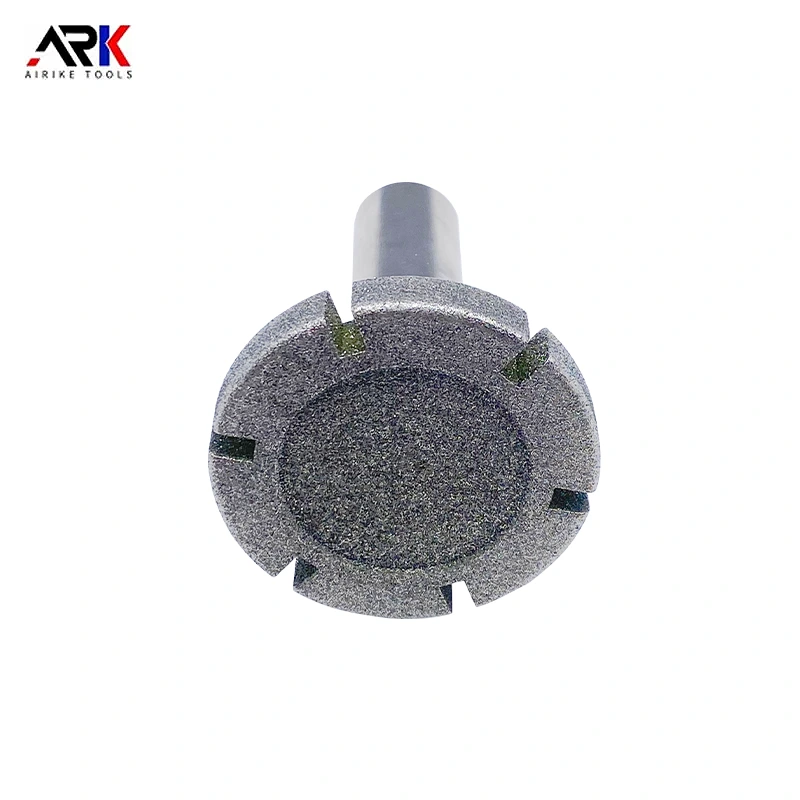

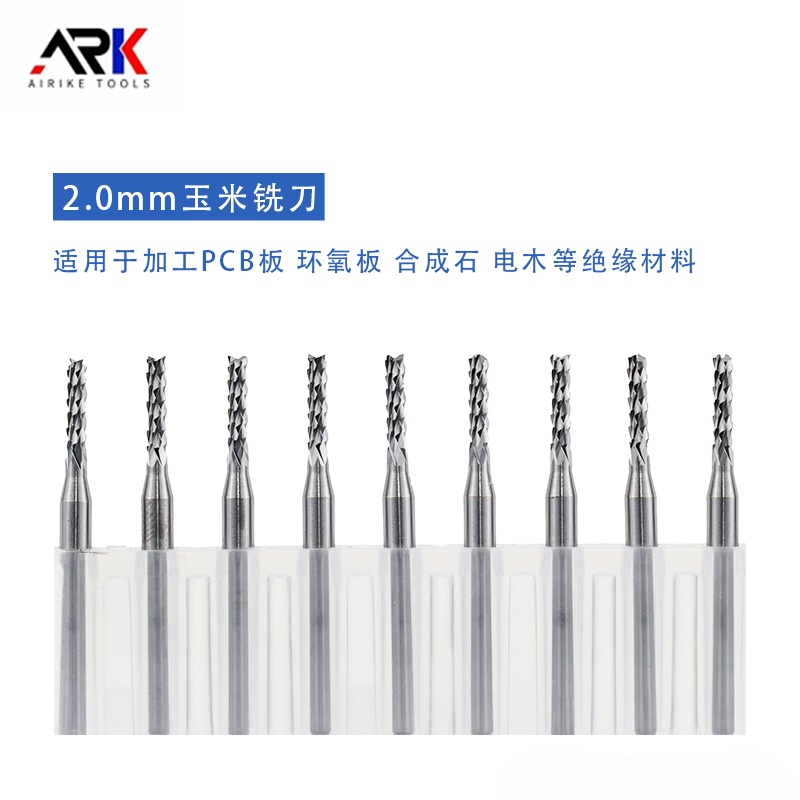

The core of Zhongyeda's high-quality Stone Carving Milling Cutter lies in its cutting part, which usually uses diamond or carbide as the cutting material. Diamond has become the first choice for processing hard stones such as marble and granite due to its extremely high hardness and wear resistance. Carbide is suitable for processing medium-hardness stones such as limestone and sandstone due to its good comprehensive performance. The cutter body is made of high-strength alloy steel or stainless steel to ensure the stability and durability of the tool under high-speed rotation.

Some high-end stone engraving milling cutters are equipped with a cooling system to reduce the cutting temperature and extend the service life of the tool by spraying coolant. Stone engraving milling cutters are usually used in conjunction with various stone engraving machines. They have good adaptability and interchangeability, making it convenient for users to choose suitable tools according to processing needs.

Used to process various patterns, texts and reliefs, such as sculptures, monuments, decorative artworks, etc.

Tombstone production: engrave names, dates and patterns on tombstones to meet personalized customization needs.

Architectural decoration: engrave decorative patterns on the surface of stone such as walls, floors, and columns to enhance the artistic value of the building.

Stone cutting: used for cutting stone slabs, such as marble, granite, etc., providing efficient and precise cutting solutions for stone processing.