Industry News

23 2025-05

23 2025-05 What are the applications of diamond tools?

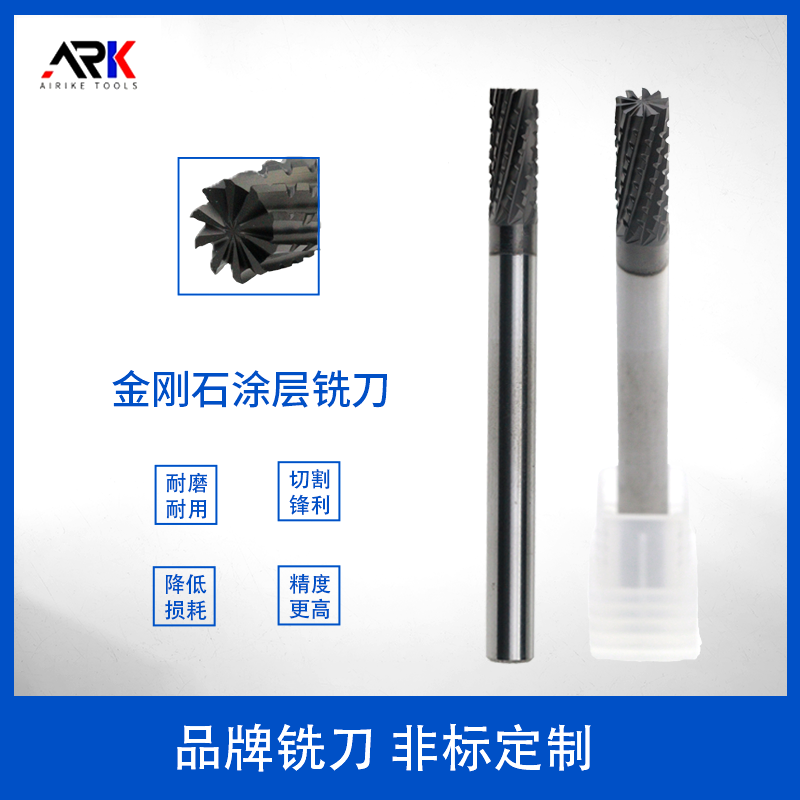

Nowadays, diamond tools are widely used. Diamond tools have the characteristics of high hardness, high compressive strength, good thermal conductivity, wear resistance, corrosion resistance, long life, etc. They are suitable for processing non-ferrous metals and non-metallic materials, and have high processing accuracy and processing efficiency in high-speed cutting.

23 2025-05

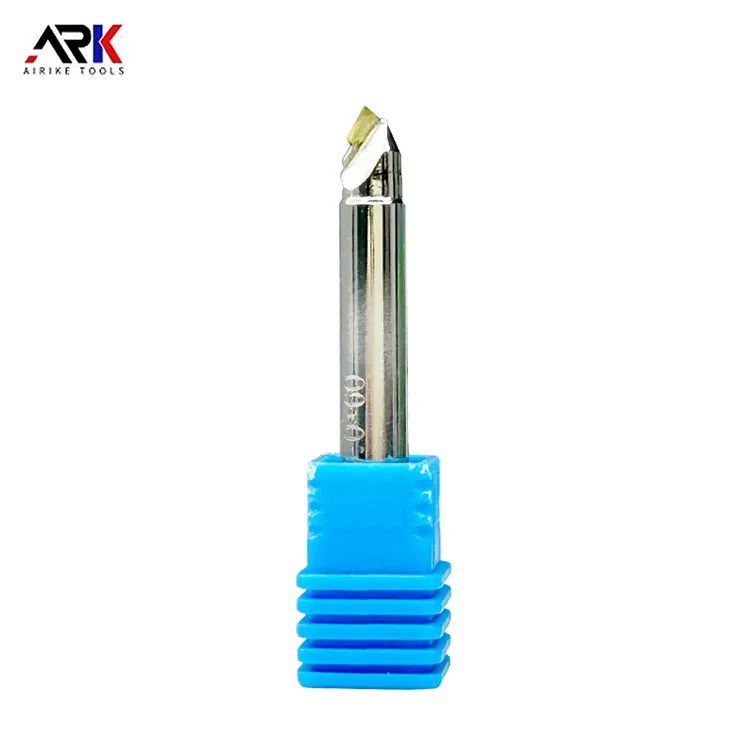

23 2025-05 Application fields of PCD tools

PCD tools are commonly used cutting tools. They are extremely wear-resistant in the finishing of some iron metals or small excess processing, and in the finishing of non-ferrous metals under good cutting temperature control.

23 2025-05

23 2025-05 How to choose a woodworking milling cutter?

The so-called milling cutter refers to a cutter body that rotates while the object being processed does not rotate, thereby achieving the purpose of cutting.

23 2025-05

23 2025-05 What is the manufacturing process of PCD tools?

Speaking of PCD tools, many people may not know about it. PCD tools have good conductive properties and can be processed by wire cutting or EDM, and can also be processed by laser.

08 2025-05

08 2025-05 What is the difference between insulating material milling cutters and ordinary material milling cutters?

Speaking of insulating material milling cutters, many people may not know about it. Insulating material milling cutters have a wide range of uses in the processing field, mainly used for precise and efficient cutting and processing of various insulating materials.

08 2025-05

08 2025-05 What materials are used for carbon fiber milling cutter coating?

There are many options for carbon fiber milling cutter coating materials, which are designed to improve the wear resistance, finish and service life of the tool.