Email Us

What is the difference between insulating material milling cutters and ordinary material milling cutters?

Speaking of insulating material milling cutters, many people may not know about it. Insulating material milling cutters have a wide range of uses in the processing field, mainly used for precise and efficient cutting and processing of various insulating materials. So what is the difference between insulating material milling cutters and ordinary material milling cutters? Next, the editor of Zhongyeda will give you a detailed introduction to this issue.

The difference between insulating material milling cutters and ordinary material milling cutters is mainly reflected in the following aspects:

1. Material selection

Insulating material milling cutters: usually made of high hardness and high wear resistance materials, such as cemented carbide or tungsten steel. These materials can resist the friction and wear generated during the processing process and extend the life of the tool. In addition, the material selection of insulating material milling cutters also needs to consider their insulation properties to ensure that there will be no safety problems such as short circuit or electric shock caused by the tool material when processing insulating materials.

Ordinary material milling cutters: may be made of more types of materials, including high-speed steel, cemented carbide, etc. The selection of these materials is mainly based on the hardness and cutting performance requirements of the processing material.

2. Cutting edge design

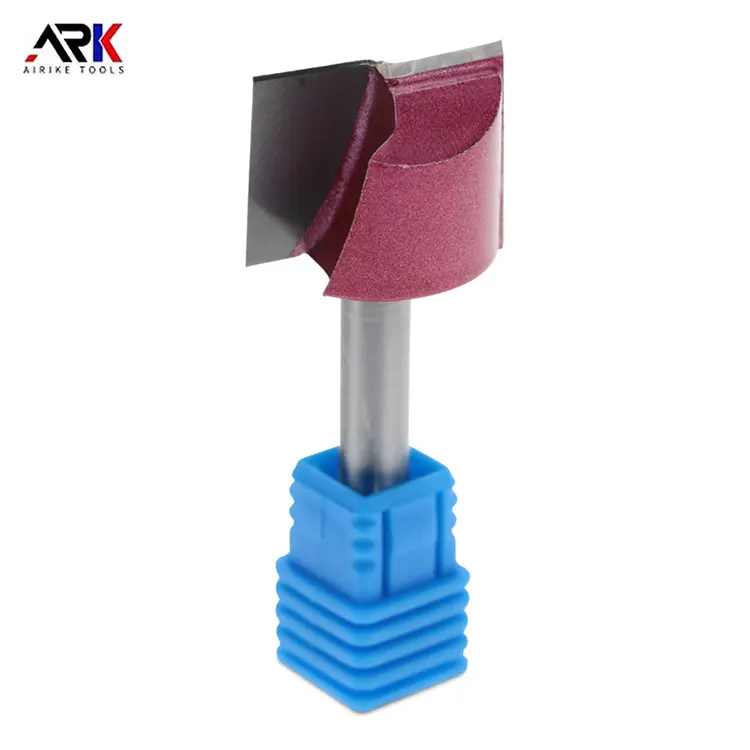

Insulating material milling cutter: Its cutting edge design is optimized for the processing characteristics of insulating materials. For example, corn milling cutter (also known as corn cob milling cutter, scale milling cutter) is a common insulating material milling cutter with dense spiral mesh on the surface and shallow grooves, which is suitable for processing composite materials such as carbon fiber and glass fiber. This design helps to ensure smooth cutting and chip removal, and reduce the impact of cutting force on the workpiece.

Ordinary material milling cutter: Its cutting edge design is more diverse. Depending on the processing material, the shape, angle and distribution of the cutting edge will be different. These designs are intended to improve cutting efficiency, reduce cutting force and thermal deformation and other problems.

3. Structural type

Insulating material milling cutter: There are various structural types, including flat structure and vertical structure. The choice of these structural forms depends on the specific processing requirements and workpiece shape. For example, vertical structure milling cutter is more suitable for processing large allowances or blanks because it can withstand greater cutting impact.

Ordinary material milling cutter: There are also many structural types, such as cylindrical milling cutter, end milling cutter, three-face milling cutter, etc. Each type of milling cutter has its specific application and purpose to meet the needs of different materials and processing strategies.

Fourth, application field

Insulation material milling cutter: mainly used to process insulation materials, such as bakelite, epoxy board, synthetic stone, carbon fiber, glass fiber and other composite materials. These materials are widely used in electrical, electronic, aerospace and other fields.

Ordinary material milling cutter: suitable for processing a wider range of materials, including metals, plastics, wood, etc. These tools are widely used in manufacturing, construction, agriculture and other fields.

The above is the difference between insulation material milling cutter and ordinary material milling cutter. There are significant differences between insulation material milling cutter and ordinary material milling cutter in material selection, cutting edge design, structure type and application field. These differences make the two milling cutters have their own unique advantages and applicability when processing different materials.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.