Industry News

08 2025-05

08 2025-05 What is the geometric angle of graphite milling cutter?

Many people are not clear about the geometric angle of graphite milling cutter. In fact, the geometric angle of graphite milling cutter is not fixed, but determined according to specific processing requirements and tool type.

08 2025-05

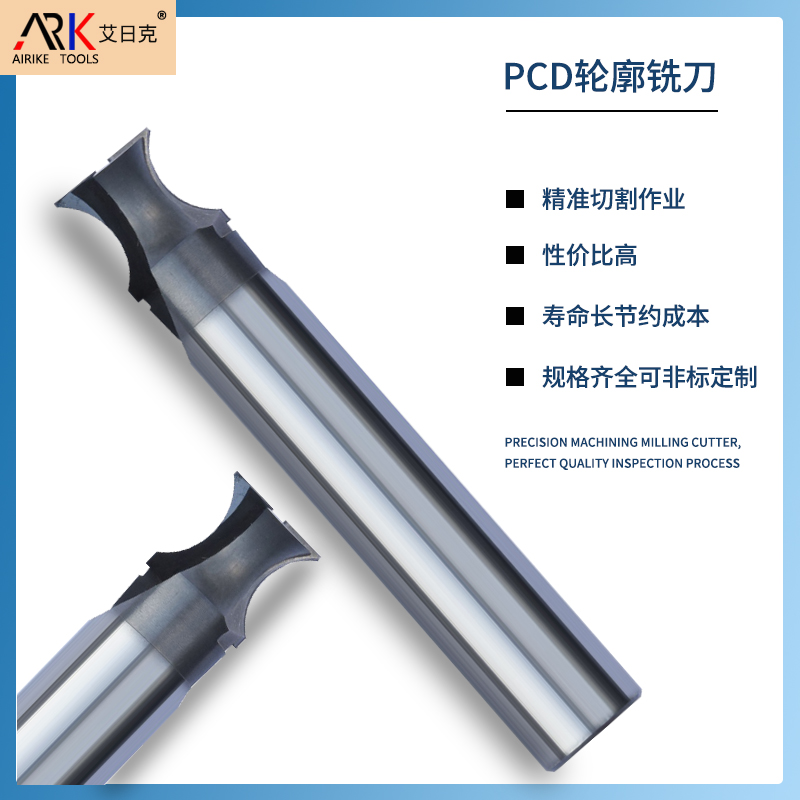

08 2025-05 The difference between PCD tools and CBN tools

There are significant differences between PCD tools (polycrystalline diamond tools) and CBN tools (cubic boron nitride tools), which are mainly reflected in the following aspects.

30 2025-04

30 2025-04 Scope Of Application Of Laser Cutting

Most of the laser cutting machine controlled by NC program operations or cutting robot. As a precision machining, laser cutting, cutting almost all of the material, including two dimensional or three dimensional cutting of sheet metal cutting.

25 2025-04

25 2025-04 Properties and characteristics of chamfering cutters

Chamfering cutters are tools used on milling machines, drilling machines, planing machines, chamfering machines and other machine tools to process 60-degree or 90-degree chamfers and tapered holes of workpieces, and chamfer edges. They belong to end mills. So what are the properties and characteristics of chamfering cutters? Let's take a look at them together!

25 2025-04

25 2025-04 The role of diamond milling cutter

Currently, in the mechanical processing and machine tool industry, diamond is made into milling cutters used on machine tools, which solves the ultra-high surface brightness, smoothness, ultra-high precision, high hardness and other performances and difficult-to-process materials required by some cemented carbide, cubic boron nitride tools, ceramic tools, high-speed steel tools, etc. when processing workpieces.

25 2025-04

25 2025-04 What are the advantages of chamfering cutters?

Chamfering cutters are drills used to countersink conical holes. They can be used to deburr, chamfer, and dig countersunk holes. The prerequisite is that there must be a guide hole for subsequent processing. The taper of the conical hole is larger at the top and smaller at the bottom. So how much do you know about the advantages of chamfering cutters? Let's take a look with the editor of Zhongyeda!