Email Us

What is the manufacturing process of PCD tools?

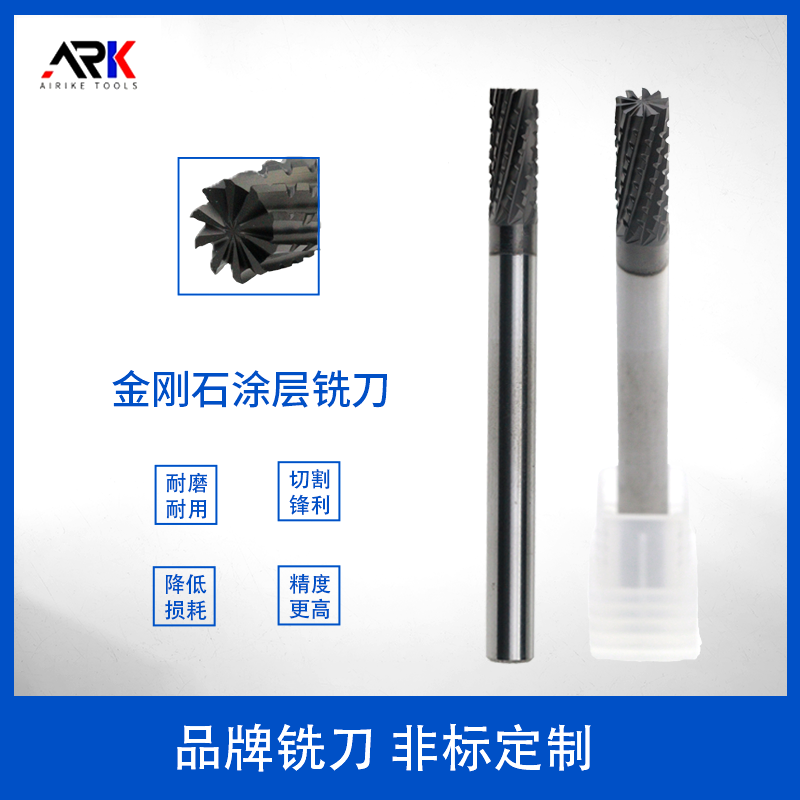

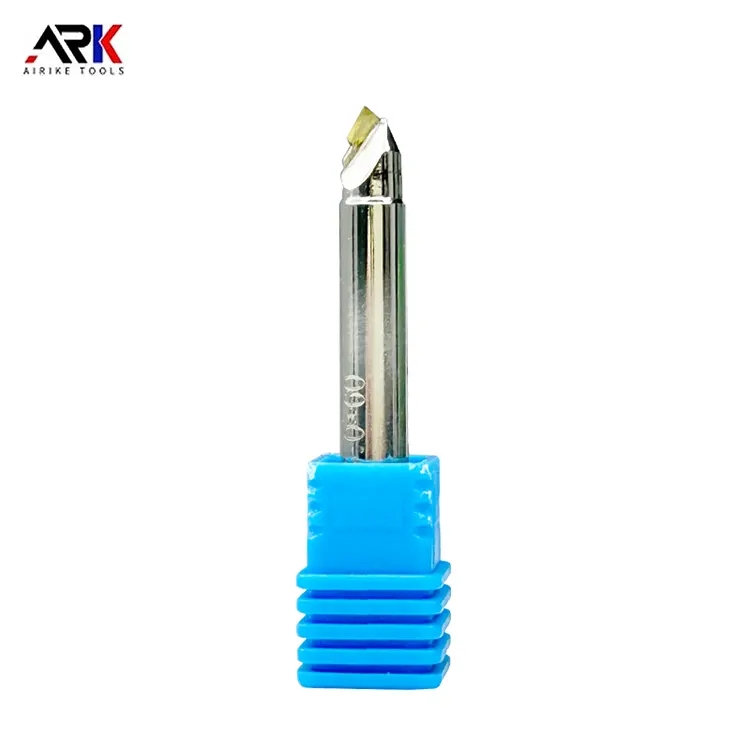

Speaking of PCD tools, many people may not know about it. PCD tools have good conductive properties and can be processed by wire cutting or EDM, and can also be processed by laser. Therefore, they are irreplaceable by other types of tools in the production of complex tools, such as step reamers and step drills for hole processing; therefore, they have been widely used in the field of modern precision manufacturing and can be customized. So what is the manufacturing process of PCD tools? Let's take a look at it together!

The manufacturing process of PCD tools mainly includes two stages:

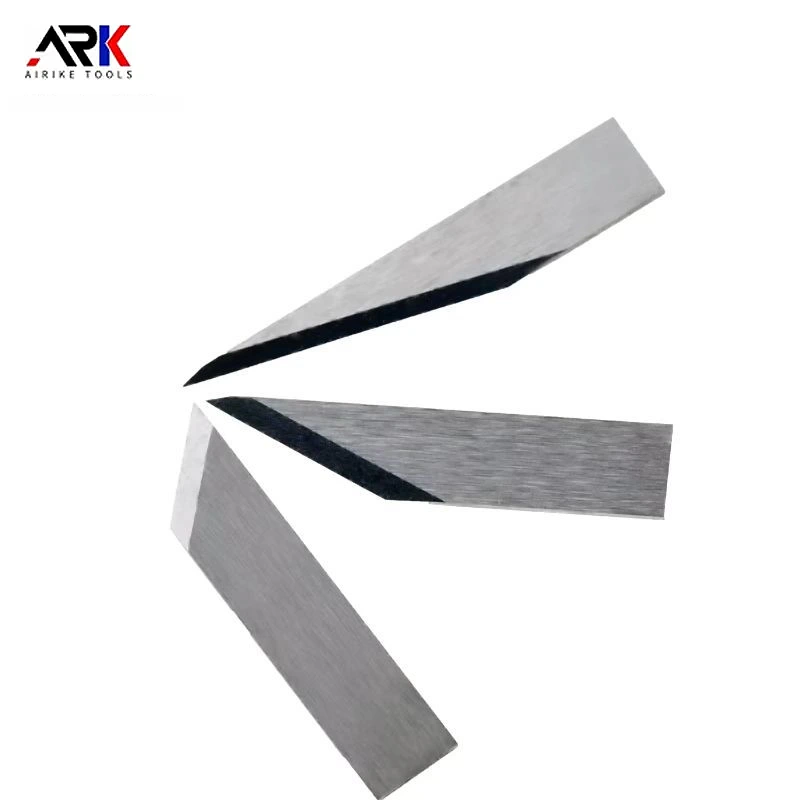

①Manufacturing of PCD composite sheets: PCD composite sheets are made of natural or artificially synthesized diamond powder and binders (including cobalt, nickel and other metals) sintered at high temperature (1000-2000℃) and high pressure (50,000-100,000 atmospheres) in a certain proportion.

During the sintering process, due to the addition of binder, a bonding bridge with TiC, SiC, Fe, Co, Ni and other components as the main components is formed between diamond crystals, and the diamond crystals are embedded in the skeleton of the bonding bridge in the form of covalent bonds. The composite sheet is usually made into a disc with a fixed diameter and thickness, and the sintered composite sheet needs to be ground and polished and other corresponding physical and chemical treatments.

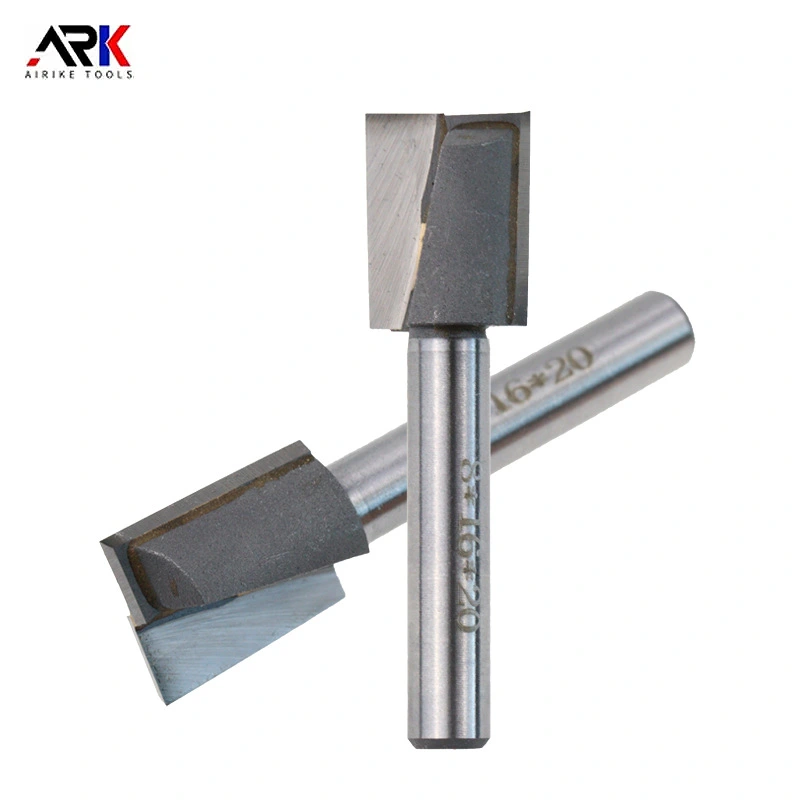

②Processing of PCD blades: The processing of PCD blades mainly includes the cutting of composite sheets, welding of blades, and sharpening of blades.

To sum up, this is the manufacturing process of PCD tools. PCD tools can help processing manufacturers obtain high processing accuracy and processing efficiency, thereby reducing processing costs and improving competitiveness.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.