Email Us

What materials are welded milling cutters suitable for machining?

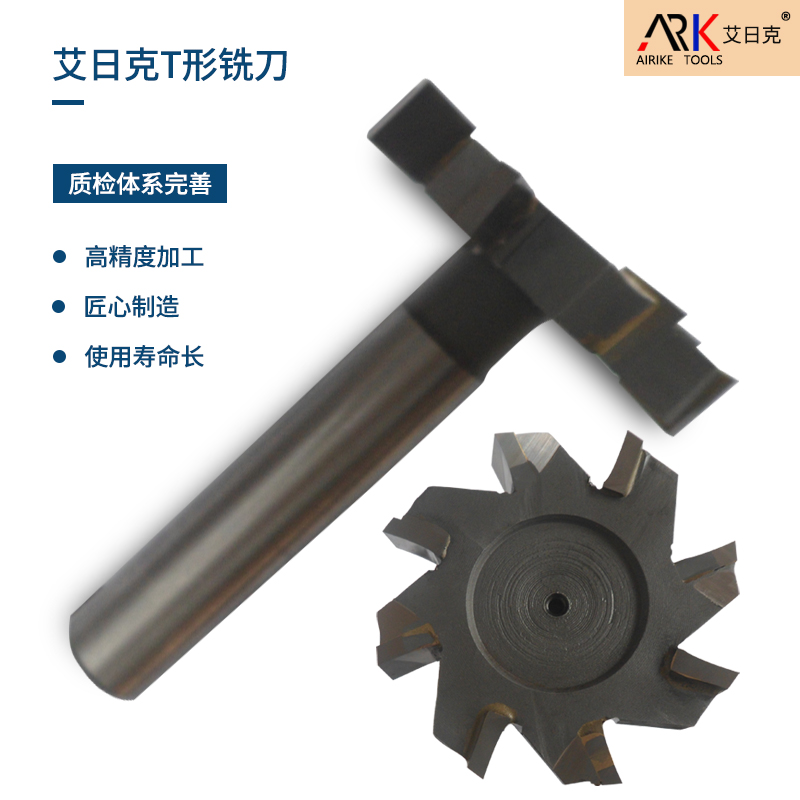

In the vast field of industrial processing, welded milling cutters cleverly weld high-performance carbide blades to the cutter body to create an integrated structure that combines rigidity and cutting efficiency, making it easy to handle both simple processing and complex tasks. So, what materials are welded milling cutters suitable for processing? Let's follow Zhongye Da's editor to uncover this mystery.

The main types of materials suitable for processing with welded milling cutters are:

1. Metal materials

Steel:

Ordinary carbon steel (e.g., 45# steel), alloy steel (e.g., 40Cr, 42CrMo), tool steel (e.g., H13, D2), etc. Tungsten carbide inserts (e.g., YG8, YT15) can efficiently machine medium to low hardness steels, while coated inserts (e.g., TiAlN, AlCrN) can handle high-hardness machining of quenched steel (HRC50 and above).

Cast iron:

Gray cast iron (HT200), ductile iron (QT500), vermicular graphite iron, etc. Specialized cast iron inserts (e.g., YG6X) enhance impact resistance through high cobalt content, making them suitable for intermittent cutting and applications with high surface finish requirements.

Non-ferrous metals:

Aluminum alloys (e.g., 6061, 7075), copper alloys (e.g., H62, QSn4-3), etc. Uncoated or diamond-coated inserts must be selected to prevent chemical affinity from causing tool adhesion.

Stainless steel and high-temperature alloys:

Austenitic stainless steel (e.g., 304, 316), nickel-based alloys (e.g., Inconel 718), etc. Use cobalt- or titanium-containing carbide inserts (e.g., YG8C) or PVD coatings (e.g., TiN) to reduce friction coefficients.

2. Non-metallic materials

Engineering plastics:

PEEK, POM, nylon, etc., require sharp edges and low-friction coatings (e.g., DLC) to reduce melting and adhesion.

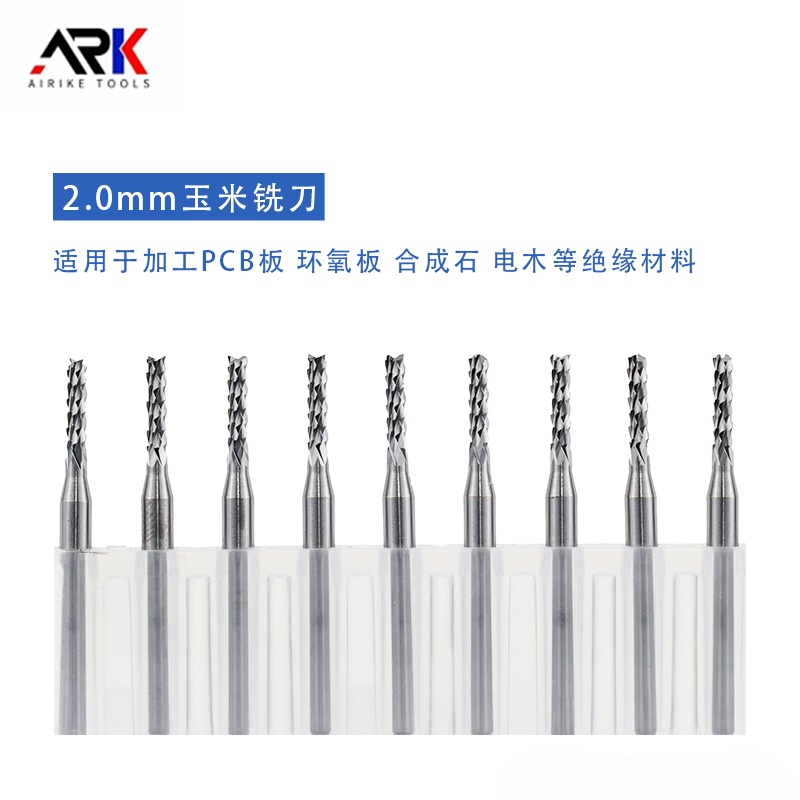

Composite materials:

Carbon fiber-reinforced plastics (CFRP), glass fiber-reinforced plastics (GFRP), etc., require specialized blades (e.g., PCD diamond-coated) to prevent delamination and burrs.

Wood and wood-based panels:

Although not a mainstream application for welded milling cutters, carbide blades can also be used for efficient slotting and forming of solid wood and MDF.

The above information on which materials are suitable for processing with welded milling cutters is shared here. Welded milling cutters perform well in metal material processing and can efficiently process a variety of metals and their alloys, such as carbon steel, aluminum alloy, and stainless steel.

In short, in the field of non-metallic material processing, welded milling cutters are also capable of processing copper, aluminum, and composite materials. Especially in high-end manufacturing fields such as mold manufacturing and aerospace, their high precision and long service life make them indispensable tools. This wide applicability makes welded milling cutters indispensable tools in industrial processing workshops.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.