Email Us

Metal cutting process inventory, which method of machining is more applicable?

In the field of machining, metal cutting is the most basic and most commonly used to a process, metal cutting processing is divided into many kinds, there are turning, drilling, boring, planing, broaching, milling and grinding. Today take you to understand these processes, so that in the actual processing can be better applied.

1. Turning

Turning refers to the rotation of the workpiece as the main movement, the cutting tool moves in a straight line as the feed movement of the cutting process.

Applicable scenarios: cylindrical, conical, end face and other rotary body parts processing

Machining equipment: CNC lathe, ordinary lathe

Advantages:

Suitable for high precision rotary parts machining

Stable cutting process, better surface quality

Can be internal and external round, threading, grooving and other processing

Disadvantages:

Not suitable for complex shapes of non-rotary parts

Limited ability to process asymmetric workpieces

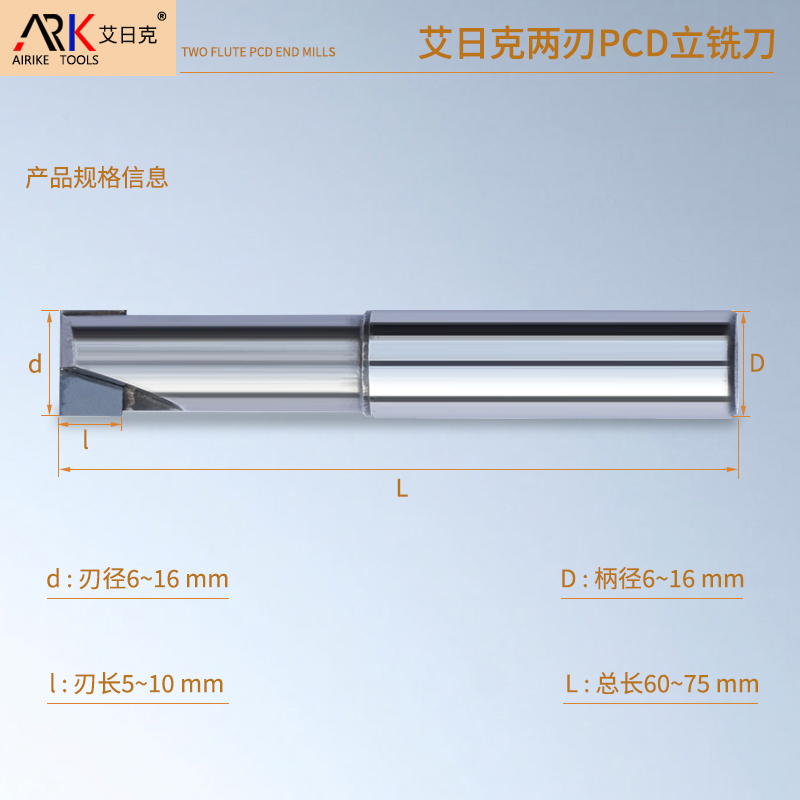

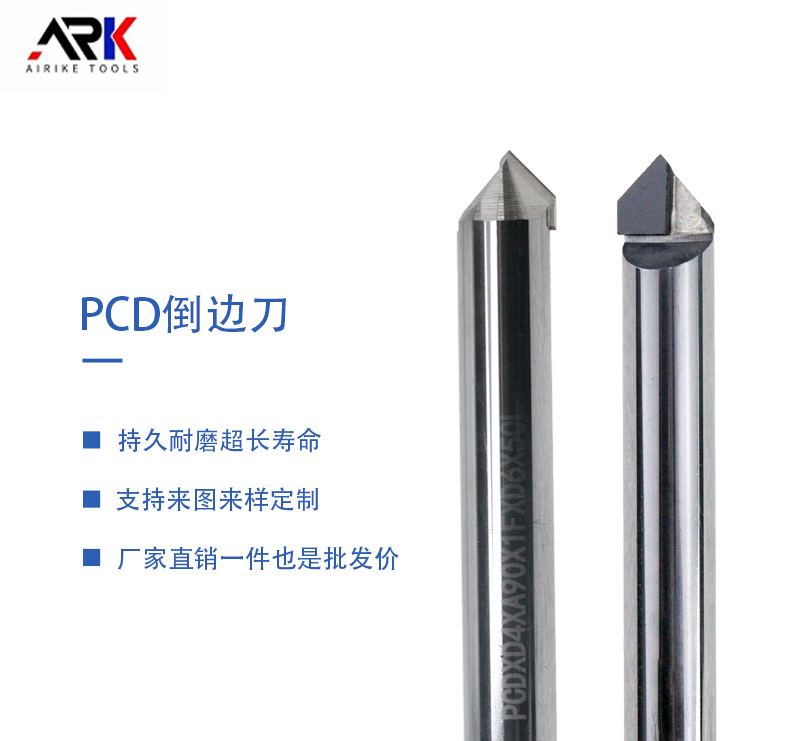

2. Milling

Milling refers to the milling cutter rotation as the main movement, the workpiece or milling cutter as the feed movement of the cutting processing method.

Applicable scenes: plane, surface, groove, gear and other complex shapes processing

Machining equipment: vertical milling machine, horizontal milling machine, CNC machining center

Advantages:

Applicable to a variety of complex shape parts

Can carry out multi-axis linkage processing, such as five-axis milling

Higher production efficiency, suitable for mass production

Disadvantages:

Faster cutting tool wear, higher costs

Higher rigidity requirements for machine tools

3. Planing

Planing refers to the cutting processing method in which the planing tool and the workpiece make reciprocating movements in the horizontal direction relative to each other in a straight line.

Applicable scenes: large plane, guide rail and other long stroke processing

Machining equipment: gantry planer, bullhead planer

Advantages:

Suitable for processing large-sized workpieces

Simple equipment structure, easy maintenance

Disadvantages:

Low machining efficiency, gradually replaced by milling

Accuracy and surface quality in general

4.Grinding

Grinding refers to the method of processing the surface of the workpiece by rotating the abrasive tool at a high linear speed.

Applicable scenarios: high-precision surface machining, hard material finishing

Processing equipment: surface grinder, cylindrical grinder, centerless grinder, etc.

Advantages:

High machining accuracy up to micron level

Suitable for hardened steel, ceramics and other hard and brittle materials

Disadvantages:

Lower machining efficiency

Grinding wheel wear requires regular dressing

5. Drilling

Drilling refers to the cutting method in which the drilling tool moves relative to the workpiece and makes axial feed movement to process holes in the workpiece.

Applicable scenes: hole processing, such as through-hole, blind hole, threaded bottom hole, etc.

Machining equipment: drilling machine, machining center, lathe

Advantages:

Specialized for hole machining, high efficiency

Can be matched with different drills, such as twist drills, center drills, deep hole drills, etc.

Disadvantages:

Only applicable to hole machining, single function

Easy to deflect and difficult to remove chips during deep hole machining.

6. Boring

Boring refers to the cutting method that uses the boring tool rotation as the main movement and the workpiece or boring tool as the feed movement.

Applicable scene: large size hole, box type parts, such as engine block

Equipment: Boring machine, machining center

Advantages:

High precision hole processing, especially large diameter deep hole

Can simultaneously complete the milling, tapping and other composite processing

Suitable for heavy, large workpieces

Disadvantages:

Large investment in equipment, suitable for professional processing

Small hole processing efficiency is not as good as drilling

7. Broaching

Broaching refers to the use of broaches in the pulling force under the action of axial movement processing workpiece inner and outer surface of the cutting processing methods.

Applicable scene: internal keyway, spline, shaped hole and other batch processing

Processing equipment: broaching machine

Advantages:

Complex shapes can be machined in one pass

High machining accuracy, good surface quality

Disadvantages:

High cost of cutting tool, only suitable for mass production

Limited machining range, not suitable for single-piece small batch production

How to choose the right machining method?

Choose according to the shape of the part:

Turning is preferred for rotary parts

Consider milling for flat surfaces or complex shapes

Narrow plane can choose planing

Choose according to the precision requirements:

High precision requirements choose grinding or broaching

Turning or milling for general precision

Choose according to the production batch:

Consider broaching or special machine tools for mass production

Single piece of small batch selection of general-purpose machine tools such as lathes, milling machines

Choose according to the hardness of the material:

High hardness materials are preferred to consider grinding

For general metal materials, various methods are available

Choosing the right cutting method can dramatically improve machining efficiency and quality! Each processing method has its own unique advantages and applicable scenarios, in actual production, often require a combination of multiple processes.

- The same milling cutter, the market phenomenon of milling cutter price difference

- Korean customers visited our company to discuss a new chapter of milling cutter cooperation!

- Zongyeda Explains - Clockwise or Counterclockwise Rotation for Woodworking Milling Cutters?

- Zhongyeda - What's the Difference Between Chamfering Tools and Centering Drills?

- How to Scientifically Determine the Milling Depth for Woodworking Milling Cutters?

- What are the characteristics and uses of graphite milling cutter?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.