Email Us

What are the advantages of chamfering cutters?

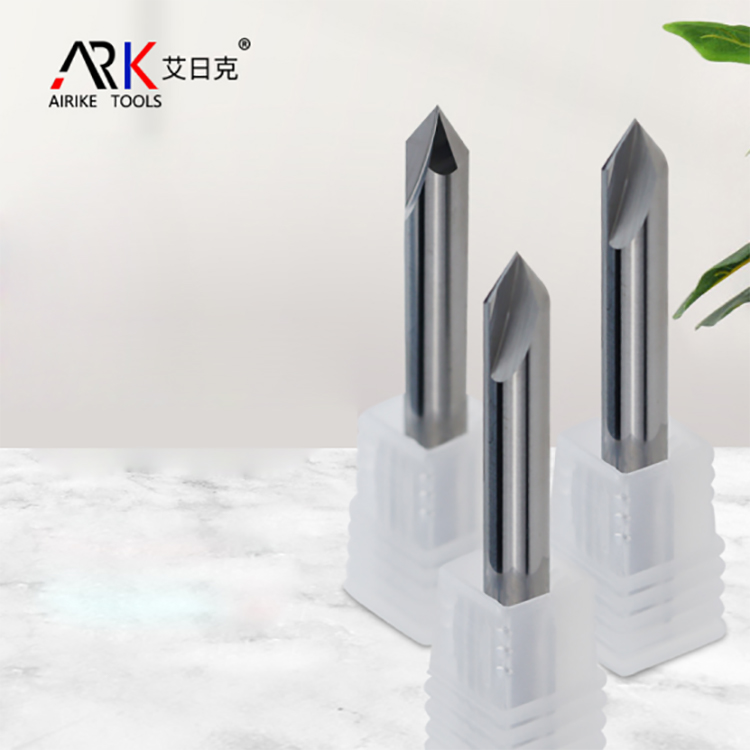

Chamfering cutters are drills used to countersink conical holes. They can be used to deburr, chamfer, and dig countersunk holes. The prerequisite is that there must be a guide hole for subsequent processing. The taper of the conical hole is larger at the top and smaller at the bottom. So how much do you know about the advantages of chamfering cutters? Let's take a look with the editor of Zhongyeda!

Advantages of chamfering cutters: Batch processing-Chamfering cutters are professional chamfering cutters designed for batch processing environments; Unique integrated design-it allows the chips generated by processing to fall more conveniently during the chamfering process, and will not cause delays in work efficiency due to tool blockage; Blades can be grinded-more convenient maintenance methods allow blades to be grinded without unloading; Only a simple one-step process-even if any tool or method cannot reach the position, the automatic through-hole chamfering cutter can quickly trim and chamfer both sides of the drilled hole in seconds; Excellent material-can process all kinds of soft or ferrous metals, and the improved blade doubles the tool life. To sum up, these are the advantages of chamfering knives. I hope this article will be helpful to you. If you have other questions about chamfering knives, you can follow Zhongyeda or leave a message to the editor. We look forward to discussing with you!

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

- How to Choose Between PCD and MCD Tools?

- Your Essential Guide to Choosing the Perfect Engraving Machine Milling Cutter

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.