Email Us

What is the main purpose of a highlight knife?

In the field of precision machining, highlight knife has become an indispensable key tool by virtue of its special blade design and material process. It can create a mirror effect with high gloss and low roughness on metal and non-metal surfaces, and is widely used in 3C products, precision molds, automotive interiors and other fields that require very high surface quality. So, what is its main role? Take a look at the detailed introduction of the editorial of Zhongye Da.

The main role:

1. Create high-gloss surface

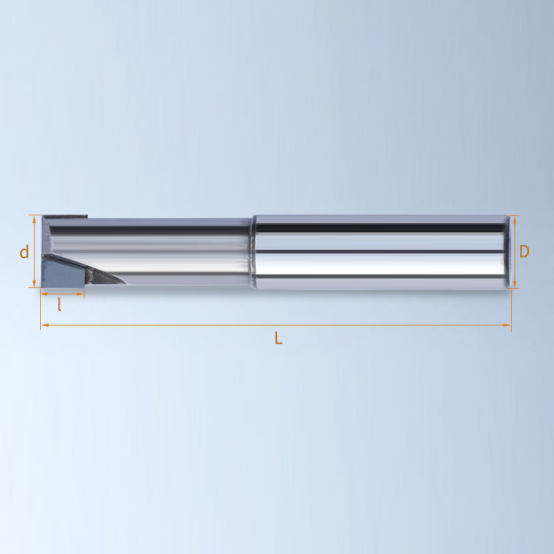

The highlight knife adopts special designs such as spherical knife body, precision edge treatment, etc., with high quality materials such as cemented carbide, diamond coating, etc., which can significantly improve the surface quality of the workpiece during machining. Take aluminum, copper and other metal and non-metallic materials finishing as an example, the surface roughness can be controlled within Ra0.1, directly realize the mirror effect, without additional polishing process, to meet the needs of high-precision processing.

2.Meet the standard of precision machining

In the shell of 3C products, such as cell phone volume keys, digital camera knobs, optical components such as aspherical mirrors and other demanding surface finish areas, highlight knife through the optimization of cutting parameters and tool structure, precise control of vibration and heat in the machining process, to effectively avoid scratches, burrs and other defects, to ensure that the surface of the workpiece is smooth and flat, to meet the strict standards of technology.

3. Enhance machining efficiency and stability

Compared with traditional knives, highlight knife in the guarantee of surface quality at the same time, greatly improve the feed rate and cutting efficiency. In the high-gloss finishing of copper, aluminum and other materials, uniform cutting volume distribution and optimized tool path, shorten the machining time, and at the same time reduce the tool wear and prolong the service life, to ensure the stability of the machining process.

4.Suitable for multi-material machining

The machining characteristics of different materials are fully considered in the design. Diamond-coated tools are suitable for hard and brittle materials such as graphite and high-silicon aluminum alloys, while carbide tools are more suitable for precision machining of non-ferrous metals such as copper and aluminum. This multi-material adaptability allows it to play an important role in many fields such as aerospace, automotive manufacturing, and consumer electronics.

The above is the whole introduction about the role of highlight knife, hope it can help you. If you have other related questions, welcome to pay attention to Zhongye Da or leave a message to exchange, looking forward to discussing more processing technology with you!

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.