Email Us

Why do some metal engraving knives require a cooling system?

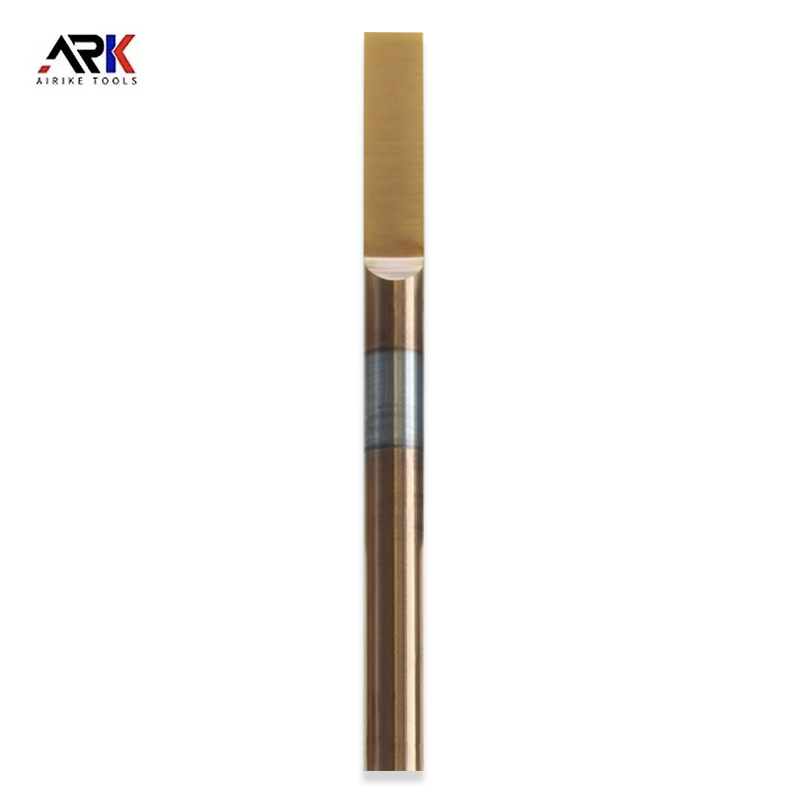

Metal engraving is a delicate craft that transforms creativity into physicality, but during the engraving process, seemingly insignificant heat can be an invisible enemy that prevents the creation of a perfect piece. So, do you know why some metal engraving knives must be equipped with cooling systems? Come and Zhongye Da editorial together to see it.

First, the root causes and effects

Metal engraving knivesin some scenarios need to be equipped with a cooling system, the fundamental reason is that the heat generated during the engraving process can have a significant impact on the tool and the workpiece. When the engraving knife and metal workpiece contact, blade friction and plastic deformation of the metal will produce a lot of heat, especially in the processing of stainless steel, titanium alloys and other high hardness, poor thermal conductivity of the metal, heat is more likely to accumulate.

Second, the heat caused by multiple problems

The heat will bring multiple problems. For metal engraving knife, high temperature will make the knife edge hardness decline, the coating may also be due to overheating failure, resulting in rapid wear and tear of the tool or even collapse; from the point of view of the engraving accuracy, the tool and workpiece heat deformation will affect the depth of the engraving and the shape of the line, in the fine engraving of this bias is more pronounced; and in the processing efficiency, in order to avoid overheating has to reduce the engraving speed, frequent replacement of worn tools will also affect the production of continuity. In terms of processing efficiency, the engraving speed has to be reduced to avoid overheating, and frequent replacement of worn tools will also affect production continuity.

Third, the cooling system working principle and function

The role of the cooling system is through a variety of ways to realize the physical cooling of the metal engraving knife. For example, the cutting fluid can take away the heat of the knife edge through convection, compressed air cooling is the use of gas expansion to absorb heat, in some taboo oil scene is more suitable. In addition, the cooling system can also wash away the metal debris generated by the carving, to avoid clogging the blade, while the metal plasticity is reduced in the low-temperature environment, which can make the carving surface smoother and reduce the subsequent polishing process.

Fourth, the cooling strategy in different scenes

Different application scenarios have different cooling needs. Like stainless steel nameplate deep carving this kind of scene, due to the friction is intense, the need for strong cooling; and in the ultra-thin aluminum plate hollowing carving, in order to avoid deformation of the thin parts, will use a more moderate cooling. In the engraving of titanium parts in the aerospace field, the cooling system not only extends tool life, but also ensures the high precision requirements of the parts.

In general, from tool loss to precision control, from productivity to special materials processing, cooling system has long exceeded the scope of auxiliary tools, become an indispensable core link in the metal engraving process chain. With the emergence of new materials, new technologies, cooling technology will continue to iterate and upgrade for the unlimited creativity of metal engraving escort, unlocking more possibilities.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.