Email Us

Products

Buy single-edge milling cutter, single-edge combination cutter, tct cutting milling cutter from Zhongyeda. High quality, great select and expert advice are our characteristics. You can rest assured to buy the products from our factory and we will offer you good after-sale service and timely delivery.

- View as

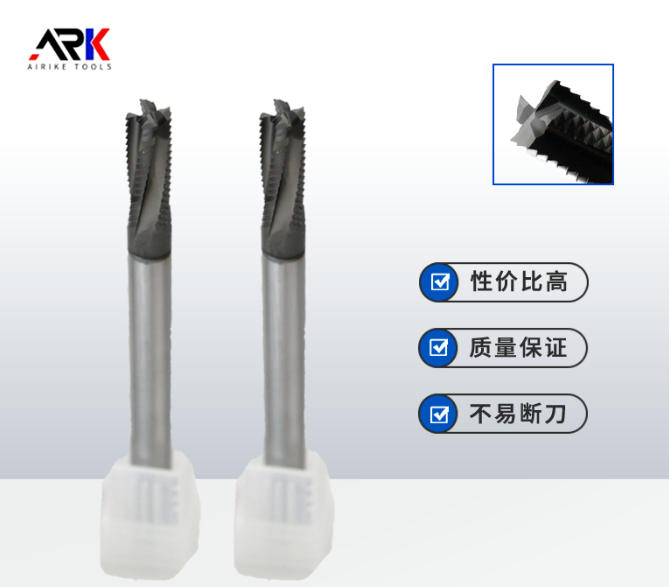

Smc Milling Cutter

Zhongyeda's high-quality SMC milling cutter is a cutting tool that is widely praised in the market. SMC milling cutter is widely praised in the market for its high performance, high precision and good chip removal performance. When using, users should choose the appropriate milling cutter specifications and types according to the processing requirements, and follow the correct use and maintenance methods to ensure processing quality and efficiency.

Stone Relief Milling Cutter

The head of Zhongyeda's high-quality stone relief milling cutter is usually made of carbide, diamond or other high-performance materials to ensure sufficient hardness and wear resistance during the engraving process. The design of this tool fully considers the hardness and engraving needs of the stone, so it has a sharp edge and a reasonable edge angle, which can easily carve delicate and precise relief patterns on the surface of the stone.

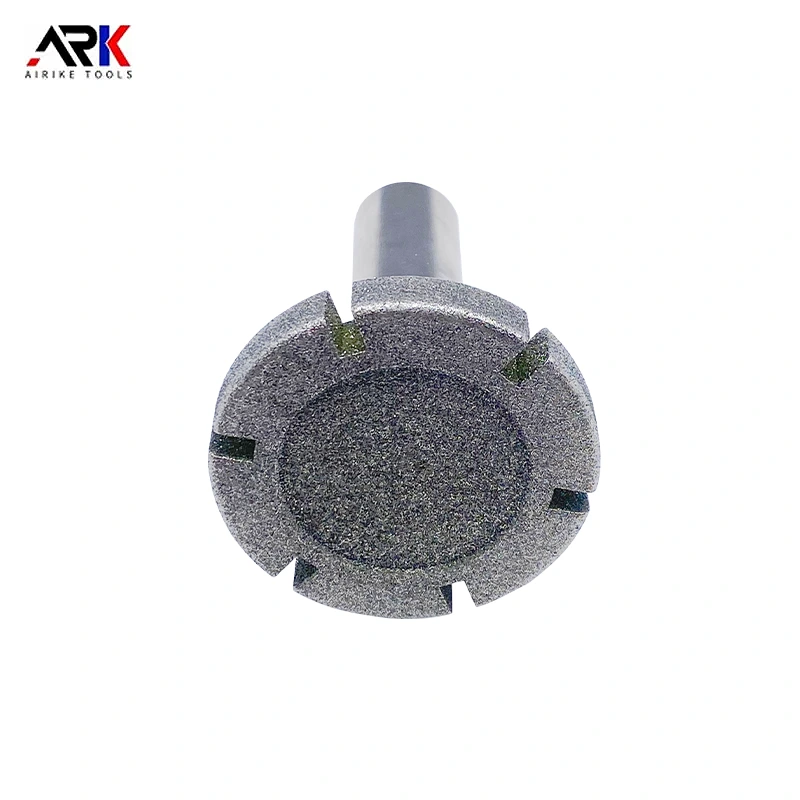

Electroplated Diamond Grinding Wheel

Our high-quality electroplated diamond grinding wheels from Zhongyeda have broad application prospects in the field of industrial processing due to their advantages of efficient grinding, no need for dressing, high working speed, wide application range and good heat dissipation performance. With the continuous advancement of science and technology and the continuous development of industry, the performance and application range of electroplated diamond grinding wheels will continue to expand and improve.

Diamond Sintered Grinding Head

Zhongyeda's high-quality diamond sintered grinding head is a professional tool that uses the high hardness and wear resistance of diamond and is widely used in grinding, polishing and other processing fields.

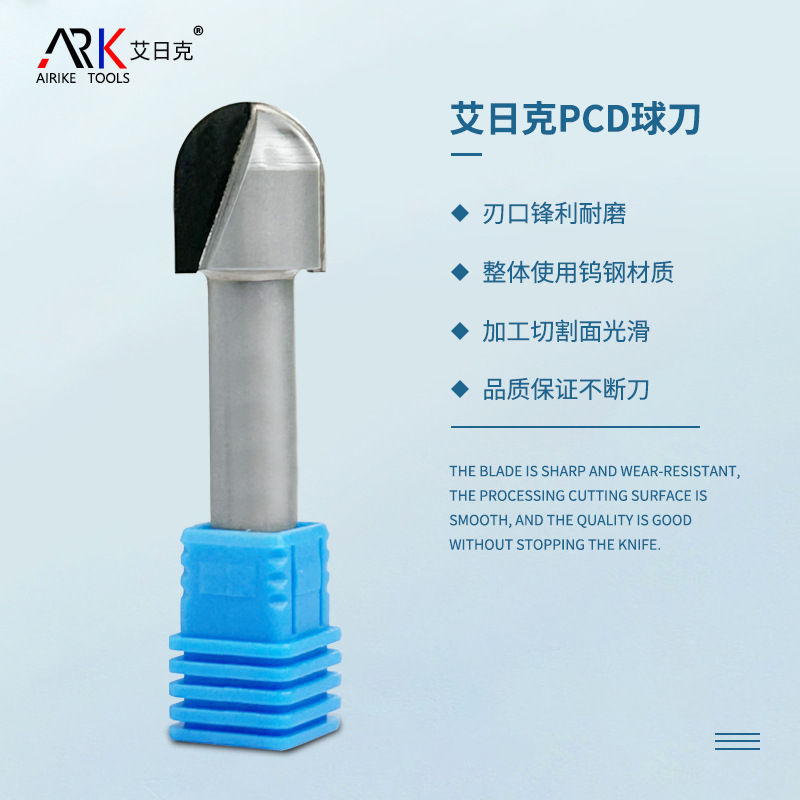

2-Edge Diamond Milling Cutter

Zhongyeda's high-quality 2-edge diamond milling cutter is a high-performance tool with unique advantages in the field of milling. With its excellent material properties and structural design, it is widely used in processing scenarios with extremely high requirements for precision and surface quality.

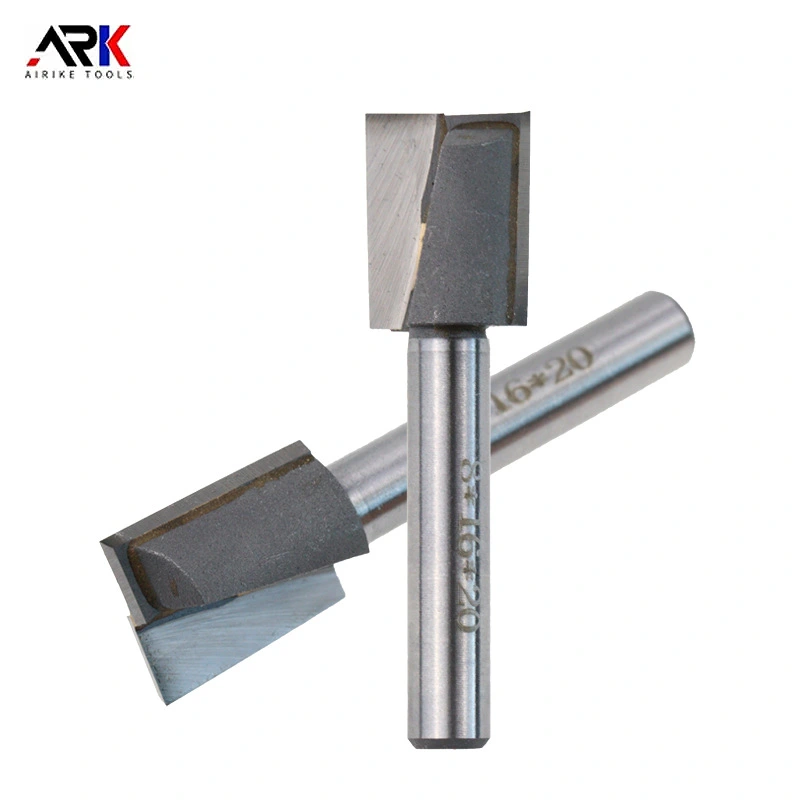

Diamond Bottom Cleaning Cutter

Zhongyeda will make the product quality meet customer satisfaction in the future. In the selection of diamond bottom cleaning cutter, the key material of the bottom cleaning knives is high-quality diamond. Diamond has the characteristics of extremely high hardness and strong wear resistance, which enables the tool to easily deal with a variety of materials with high hardness or special textures such as hardwood, density board, artificial stone, ceramics, etc. during the bottom cleaning process. Even in the face of long-term and high-intensity bottom cleaning operations, the diamond cutter head can remain sharp, greatly reducing the wear and replacement frequency of the tool, and in the long run, effectively reducing the processing cost for users.

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.