Email Us

What is the difference between PCD cutting tools and single-crystal cutting tools?

In the field of precision machining, PCD cutting tools and single-crystal diamond cutting tools are two highly regarded ultra-hard material cutting tools. With their exceptional hardness and wear resistance, they make it possible to process a variety of difficult-to-machine materials. However, these two types of cutting tools have significant differences in structure, performance, and application. Understanding these differences is crucial for selecting the appropriate cutting tool. Below, the Zongye da team will introduce these differences to you.

The differences between PCD cutting tools and single-crystal cutting tools are as follows:

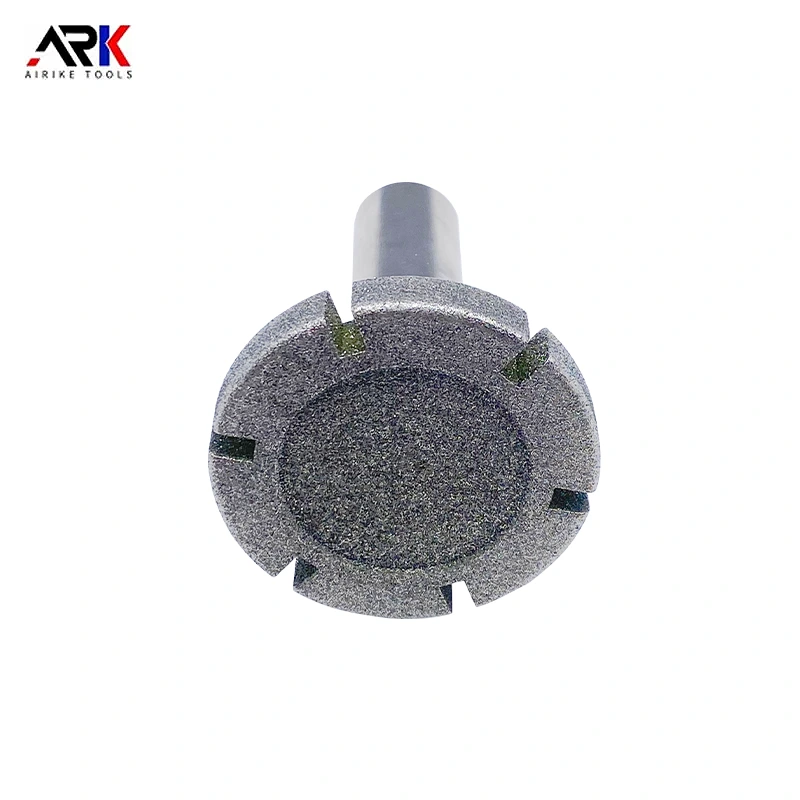

The core advantage of PCD cutting tools lies in their extreme hardness and wear resistance, with a hardness of up to 8000 HV, far exceeding that of traditional cemented carbide cutting tools. This makes PCD cutting tools excel in machining high-hardness materials such as aluminum alloys, copper alloys, graphite, composite materials, and various non-metallic materials.

PCD cutting tools have an extremely high thermal conductivity, approximately five times that of copper. This property enables them to effectively dissipate heat during high-speed cutting, reduce thermal deformation, and maintain cutting tool geometric accuracy. Additionally, PCD cutting tools exhibit excellent chemical stability, making them unlikely to react chemically with the workpiece material. They are particularly suitable for machining non-ferrous metals and their alloys, achieving extremely high surface finish quality. However, PCD cutting tools also have their limitations, such as poor toughness, making them prone to chipping when encountering hard particles or impacts during machining. They are also unsuitable for machining ferrous metals like steel, as diamond reacts chemically with iron at high temperatures, causing graphitization and failure.

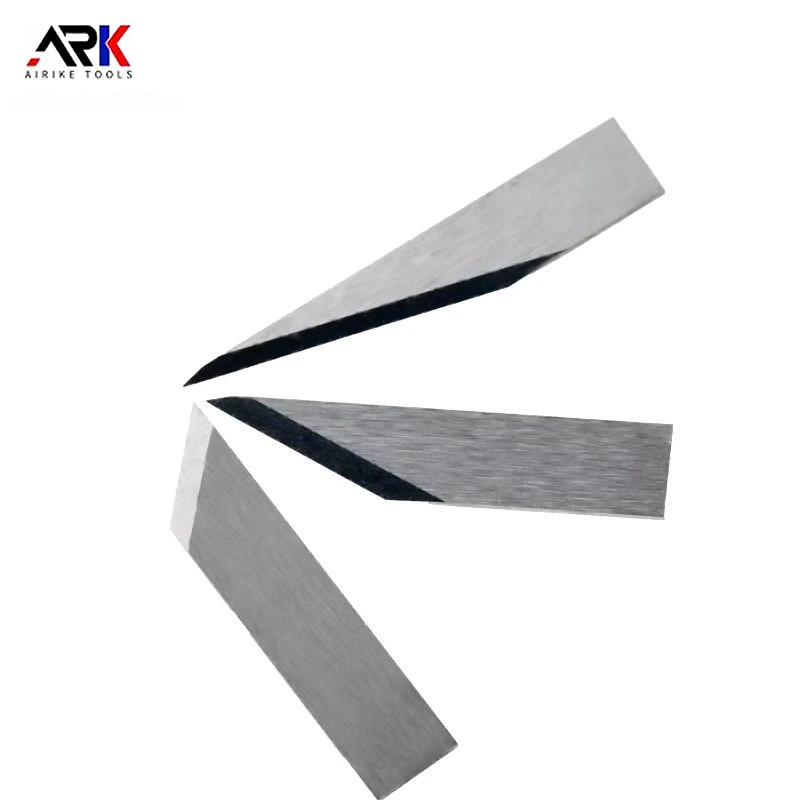

In contrast, single-crystal diamond cutting tools are precision-machined cutting tools made from a single, intact, defect-free diamond crystal. They contain no metallic binders and are composed of pure diamond structure. The hardness of single-crystal diamond cutting tools exceeds that of PCD cutting tools, reaching over 10,000 HV, and they exhibit extremely high compressive strength and wear resistance. Their advantage lies in their ability to achieve atomic-level precision cutting, producing extremely smooth surfaces (Ra values as low as the nanometer level) and extremely high dimensional accuracy. This makes single-crystal diamond cutting tools a powerful tool in the field of ultra-precision machining, widely used in high-demand applications such as optical lenses, semiconductor wafers, precision molds, and hard disk drives.

Single-crystal diamond cutting tools also exhibit excellent thermal conductivity and chemical inertness, making them particularly suitable for ultra-precision machining of non-ferrous metals. However, the manufacturing cost of single-crystal diamond cutting tools is extremely high, as they must be cut and ground from large-sized natural or synthetic single-crystal diamond rough stones into the desired shape. Their shape is constrained by the crystal structure of the rough stone, typically limiting them to specific angles, resulting in lower versatility compared to PCD cutting tools.

Additionally, single-crystal diamond cutting tools are not suitable for machining ferrous metals such as steel. They combine high hardness with a certain degree of toughness, making them suitable for mass production. However, if the machining task requires surface roughness at the nanometer level, extremely high dimensional accuracy, or the processing of surfaces with special optical or physical properties—such as ultra-precision molds or optical components—then single-crystal diamond cutting tools are the only viable option, despite their higher cost.

The above is the difference between PCD cutting tools and single crystal cutters, PCD tools and single crystal diamond tools each have their own strengths. pcd tools with its excellent comprehensive performance and relatively low cost, in many precision machining areas occupy an important position; while single crystal diamond tools with unparalleled machining accuracy and surface quality, in the field of ultra-precision machining plays a key role. Understand the difference between them, according to the specific requirements of the machining task to make a wise choice, is to ensure the quality of machining, improve productivity is the key.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.