Email Us

How to maintain the graphite milling cutter?

Good maintenance not only extends the life of the cutting tool, but also ensures machining accuracy and surface quality. So how much do you know about the maintenance of graphite milling cutter? Below, Zhongye Da editorial will introduce the graphite milling cutter maintenance method in detail.

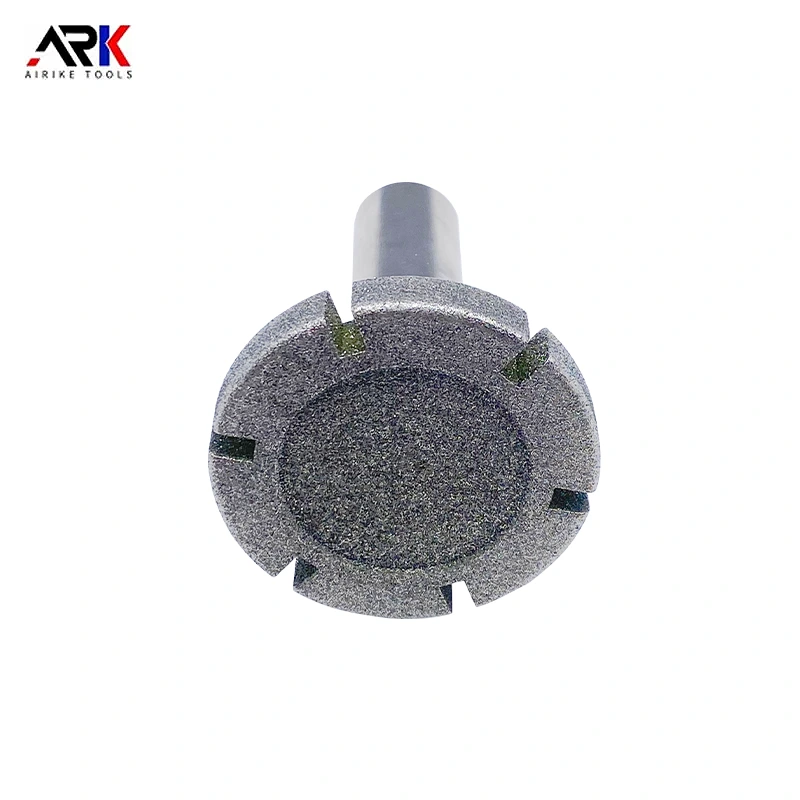

Graphite milling cutter designed for processing high hardness, high brittleness of graphite material design, widely used in molds, electronics, semiconductor field, due to graphite abrasive, cutting tool maintenance to extend the life of the tool, to protect the machining accuracy is critical, the specific methods are as follows.

First, daily cleaning: after processing with compressed air to blow off the surface of the cutting tool and the graphite dust of the clamping system, stubborn residue with a special cleaner with a soft cloth to wipe, avoid scraping with a metal brush, to avoid damage to the cutting tool; regular inspection of the clamping system, to ensure that the clamping force is appropriate, to prevent vibration aggravate wear.

Second, regular inspection: observe whether the knife edge chipping, wear or coating peeling, with the help of machine tool monitoring system to grasp the status in real time, wear and tear in a timely manner when grinding or replacement, to avoid scrapping of the workpiece.

Storage management: store the cutting tool in a dry, ventilated, non-corrosive environment, with a special tool box to prevent collision; long-term idle tools need to be coated with antirust oil, wrapped in rust-resistant paper, away from high temperatures and high humidity and strong magnetic fields.

Four, grinding and replacement: passivated cutting tool priority professional grinding, to ensure that the geometric parameters and coatings up to standard and testing qualified; can not be grinding or high cost timely replacement, the new knife needs to be adapted to the processing requirements.

Fifth, parameter optimization: reasonable setting of cutting speed, feed rate and depth, too high is easy to aggravate the wear, too low affects the efficiency; with air-cooled or micro-lubrication to reduce friction and heat accumulation.

Sixth, personnel training: regular training of operators, so that they master the correct maintenance methods, the establishment of cutting tool management system, standardize the use, inspection, repair and grinding process.

The above graphite milling cutter maintenance methods for you to share here, do a good job of all-round maintenance, in order to give full play to the performance of graphite milling cutter, improve processing quality and efficiency.

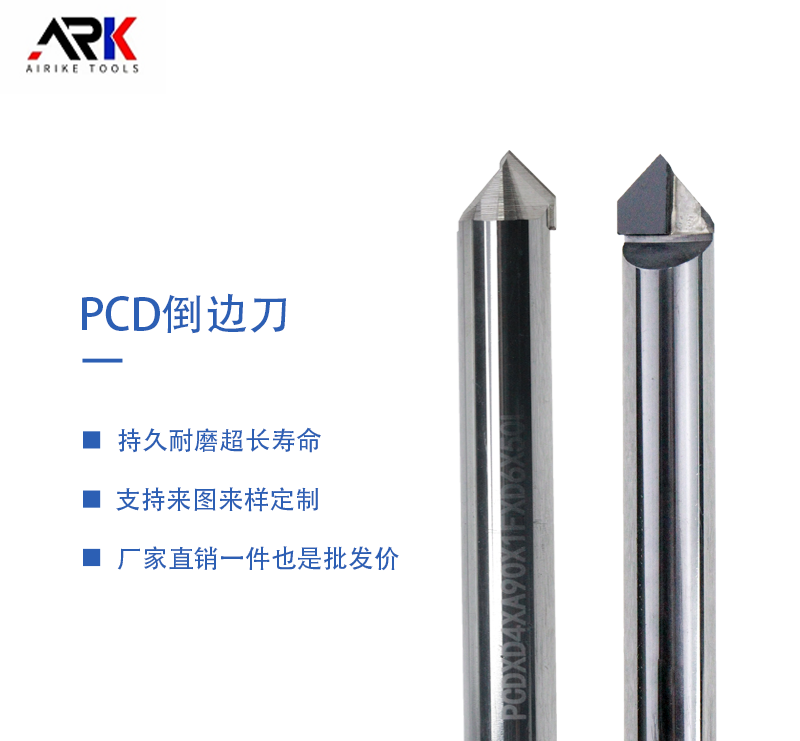

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.