Email Us

Chamfering Cutter

Zhongyeda chamfering cutter also has a rich material. Chamfering cutters made of high-speed steel have good toughness and cutting performance as well as high durability. The price is relatively low. They are widely used in chamfering of ordinary metals and non-metallic materials, such as aluminum alloys, copper alloys and wood. Chamfering cutters made of cemented carbide have extremely high hardness and strong wear resistance. They can withstand higher cutting speeds and greater cutting forces. They are suitable for processing materials with higher hardness, such as steel, and perform well in chamfering with high precision and high surface quality requirements.

In terms of function, the chamfering cutter plays a significant role. On the one hand, it can remove burrs and sharp angles on the edge of the workpiece, making the edge smooth and rounded, which not only improves the appearance quality of the workpiece, but also effectively avoids scratches and other injuries to the operator during subsequent use. On the other hand, chamfering can improve the assembly performance of the workpiece. For example, in the assembly of mechanical parts, the chamfered edge is easier to fit between parts, reducing assembly resistance and improving assembly accuracy and efficiency. In addition, in some special processing technologies, chamfering can also create better conditions for subsequent welding, painting and other processes, and enhance connection strength and coating adhesion.

Whether in the processing of precision mechanical parts or in the daily production of hardware and wood products, chamfering knives have become important tools for achieving fine edge processing and improving product quality with their unique structure, diverse material selection and powerful functions.

1. Single-edged chamfering knife

Features: There is only one cutting edge, the cutting force is small, and the cutting surface is relatively flat. It is suitable for processing workpieces with high requirements for cutting surface and strict precision requirements, such as precision instrument parts, electronic components, etc. However, since there is only one cutting edge, it is easy to wear, the service life is relatively short, and the cutting speed is slow, and the processing efficiency is low.

Applicable scenarios: Commonly used for chamfering in one direction, such as chamfering the edges of some small parts, or chamfering with high requirements for specific angles and precision.

2. Double-edged chamfering cutter

Features: It has two cutting edges and can process chamfers in two directions at the same time. Compared with single-edged chamfering cutters, it has higher processing speed and efficiency, can effectively shorten processing time and improve production efficiency.

Applicable scenarios: It is suitable for situations where two opposite surfaces of the workpiece need to be chamfered at the same time, such as chamfering the two ends of some shaft parts, or chamfering the adjacent two sides of rectangular parts.

3. Three-sided staggered cutter

Features: It can complete the tasks of multiple cutting surfaces at the same time, the cutting effect is more ideal, and the processing efficiency is greatly improved. However, due to its relatively complex structure and high manufacturing process requirements, the processing cost is also high.

Applicable scenarios: It is often used for some workpieces with more complex shapes that need to chamfer multiple surfaces at the same time, such as mold cavities, complex mechanical parts, etc.

4. Multi-edged chamfering cutter (such as four-edged cutter)

Features: It is also called multi-tooth cutter, with a large processing depth, a smooth cutting process, and can withstand large cutting forces. Due to the large number of edges, the cutting amount shared by each edge is relatively small, so the tool wear is relatively uniform and the service life is long.

Applicable scenarios: Suitable for chamfering of larger diameter holes and mass production scenarios with high processing efficiency requirements, such as chamfering of holes in automobile engine cylinder blocks.

5. Inner hole chamfering tool

Features: It is composed of a tool bar, a blade and an elastic closed groove. The front end is a hole entry guide, the front end of the blade is 45 degrees, the inner end is 33 degrees, and the notch is 6 degrees. It is easy to clamp and can be used in almost all rotary processing equipment. It has a wide range of applications and can process holes ranging from 0.8mm to 25mm. It can effectively process burrs on the back of holes and cross-hole burrs.

Applicable scenarios: It is mainly used for chamfering and deburring of inner holes of various mechanical parts. It is widely used in the processing of parts in aviation, military industry, automobile and other industries, such as chamfering of inner wall holes of engine cylinder blocks, chamfering of through holes of cylinders and spheres, etc.

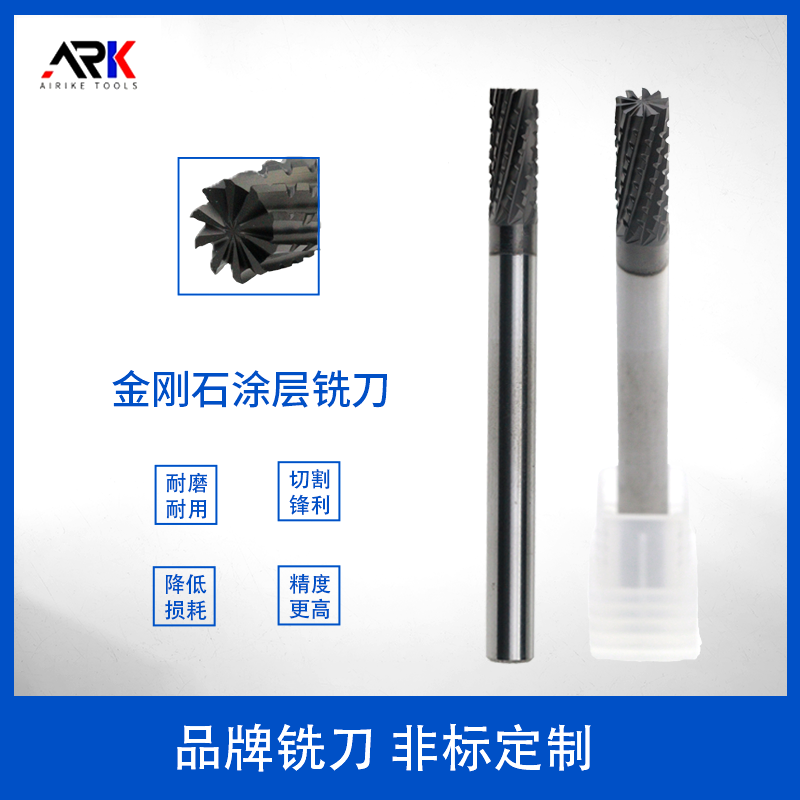

6. Deburring and chamfering cutter

Features: Using high-speed rotating blades, through precise cutting action, to achieve smooth transition and angle adjustment of workpieces, with the advantages of high precision, high efficiency, good safety, etc. The blades are made of carbide materials, with excellent wear resistance and impact resistance.

Applicable scenarios: Suitable for workpieces of various materials, including metals, plastics, ceramics, etc., widely used in automobiles, aviation, electronics, medical, new energy, rail transportation and other industries, used to remove burrs on the surface of workpieces and perform chamfering to improve the quality and service life of workpieces.

7. Floating deburring and chamfering cutter

Features: It can automatically compensate between the actual contour of the workpiece and the program. Through the floating mechanism of the tool holder, it can move along the uneven edge of the workpiece for processing, so that the tool has an edge compensation of 5-10mm. The pressure on the edge of the workpiece can be adjusted through the adjustment mechanism inside the tool holder. It has the advantages of maintenance-free, high feed and high speed, and uniform chamfering size.

Applicable scenarios: Suitable for processing workpieces with irregular contours and uneven surfaces. It can effectively improve processing accuracy and efficiency in CNC processing and reduce manual intervention.

8. Other special types of chamfering cutters

(1) Spiral chamfering cutters

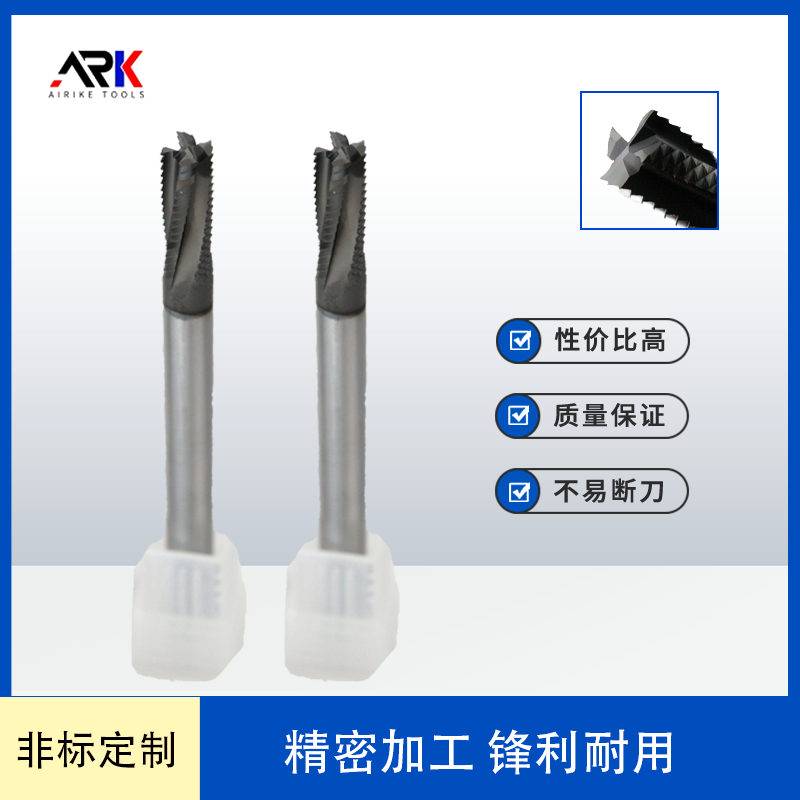

Features: With a unique spiral blade design, it is efficient, sharp and durable. Its excellent sharpness can quickly and accurately complete the chamfering work, greatly improving production efficiency. Its durability greatly extends the service life of the tool and reduces the frequency and cost of tool replacement. It is also suitable for a variety of materials, such as copper, aluminum, steel, stainless steel, titanium alloy and quenched materials.

Applicable scenarios: It performs well in the processing of engine parts and transmission system parts in the automotive manufacturing field, as well as the high-precision processing of complex parts in aerospace and precision instrument manufacturing.

(2) Angle-adjustable chamfering cutters

Features: The chamfering angle can be easily adjusted within a certain angle range. For example, the C-type chamfering cutter of BIG DAISHOWA can be adjusted within the range of 5°-85°, which can reduce the number of tools used in processing and the processing time. Its small cyclone chamfering cutter also has the triple functions of 4 blades, small blade diameter and new coating, which greatly improves the processing efficiency.

Applicable scenarios: It is suitable for various workpieces and processing scenarios that need to be chamfered at different angles, and has strong versatility and flexibility.

(3) Micro chamfering tool

Features: Generally, it is a front and back chamfering tool made of cemented carbide, with a very small diameter. It can also perform front and back chamfering on complex workpiece shapes, which is convenient for chamfering the edges of workpieces at deeper positions and the back of drilled holes. The long neck size has been standardized, and the tool tip is usually coated with chromium nitride with high resistance to welding.

Applicable scenarios: Mainly used for processing small and precision parts, or chamfering in limited space, such as electronic components, micro-mechanical parts, etc.

-

Address

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

-

Tel

-

E-mail

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.