Email Us

How to choose the right chamfering milling cutter?

In mechanical processing and woodworking, chamfering is a common but crucial process. It not only removes burrs from the edges of parts and prevents scratches, but also improves stress concentration and facilitates subsequent assembly. But with so many chamfering milling cutters on the market, how can you choose the right type for you? Now, let's take a look with Zhongye Da!

First, clearly defining your machining requirements is the foundation for selection. What material are you chamfering? Is it hard steel, or relatively soft aluminum alloy or wood? Different materials have different requirements for tool hardness and wear resistance.

For example, machining steel usually requires carbide tools, while machining wood can use high-speed steel or special woodworking chamfering milling cutters. At the same time, consider the size requirements of the chamfer. Do you need a fine chamfer with a small angle and small chamfer radius, or a quick process with a large angle and large chamfer radius? This directly affects the geometry and size specifications of the tool you choose.

You also need to pay attention to the type and structure of the chamfering milling cutter. There are three main types of chamfering cutters.

1. Integral type

The cutting part and the shank of the tool are integrated, with a simple structure, easy to use, and usually relatively low in price. It is suitable for occasions where the precision requirements are not particularly high and the batch size is not large.

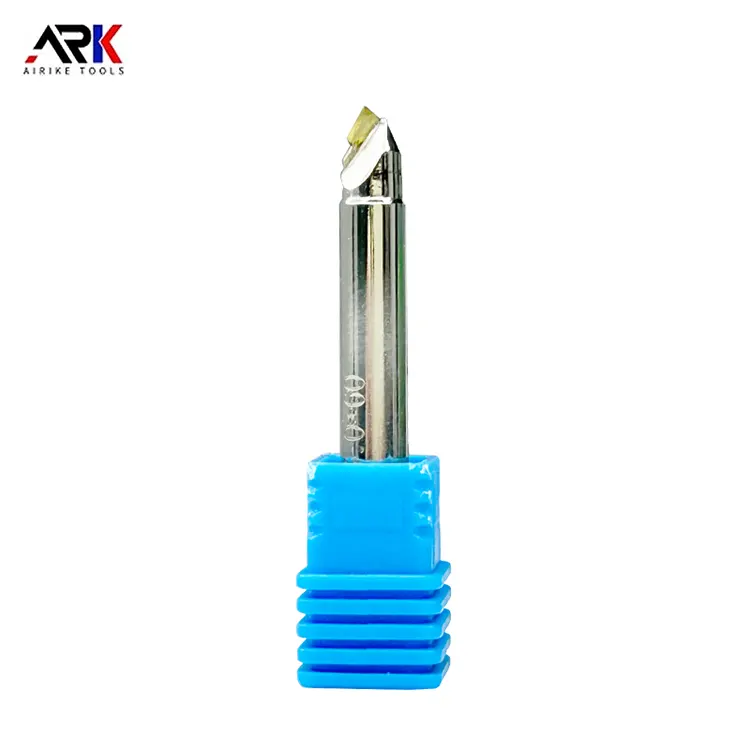

2. Indexable type

The tool head can be replaced, allowing a single tool handle to accommodate multiple blades of different sizes or angles. The advantage of this tool lies in its cost-effectiveness: when the blade wears out, only the blade needs to be replaced rather than the entire tool, reducing downtime and improving efficiency. It is particularly suitable for large-scale production.

3. Modular chamfering system

This is a more advanced configuration, typically including a dedicated chamfering machine or machine tool accessory. The tool head can be quickly replaced, making adjustments convenient and ensuring high precision. It is suitable for applications with extremely high requirements for chamfering quality and efficiency.

Additionally, the installation method of the chamfering tool must be considered. Is it directly mounted on the machine tool spindle, or does it require a specific tool holder or accessory? Ensure the selected tool is compatible with your equipment.

Finally, do not overlook operational convenience and safety. Choose tools with comfortable grips and simple adjustments to reduce operator fatigue and improve work efficiency. Additionally, verify that the tool has proper safety guards to ensure safe operation.

In short, carefully evaluate your specific needs and compare the advantages and disadvantages of different types of tools to select the right tool that can bring you an accurate, efficient, and safe chamfering milling cutter experience, adding professional and exquisite details to your workpieces.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.