Email Us

What are the performance advantages of single crystal diamond tools?

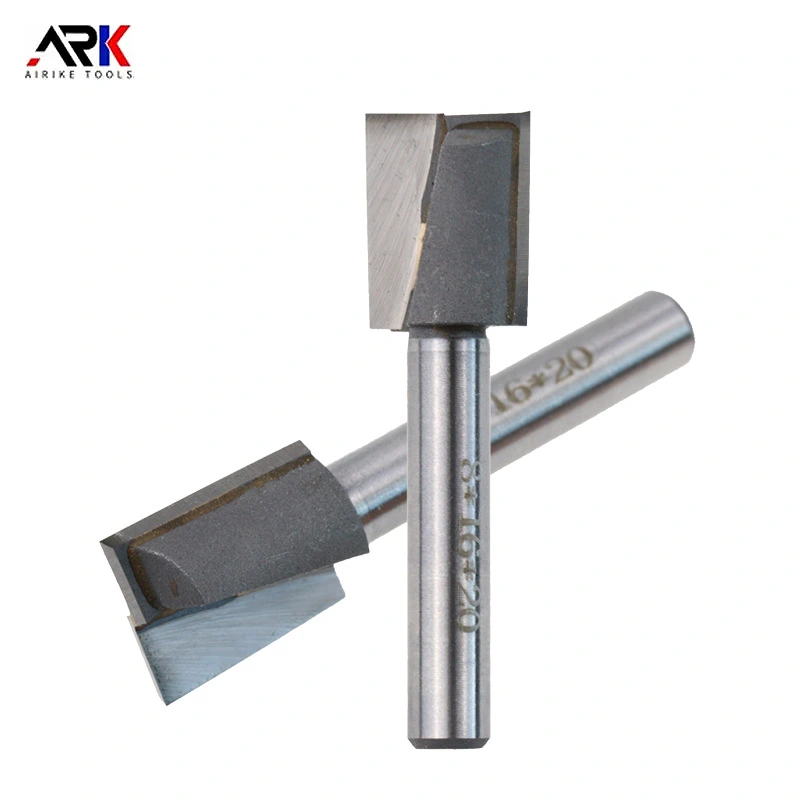

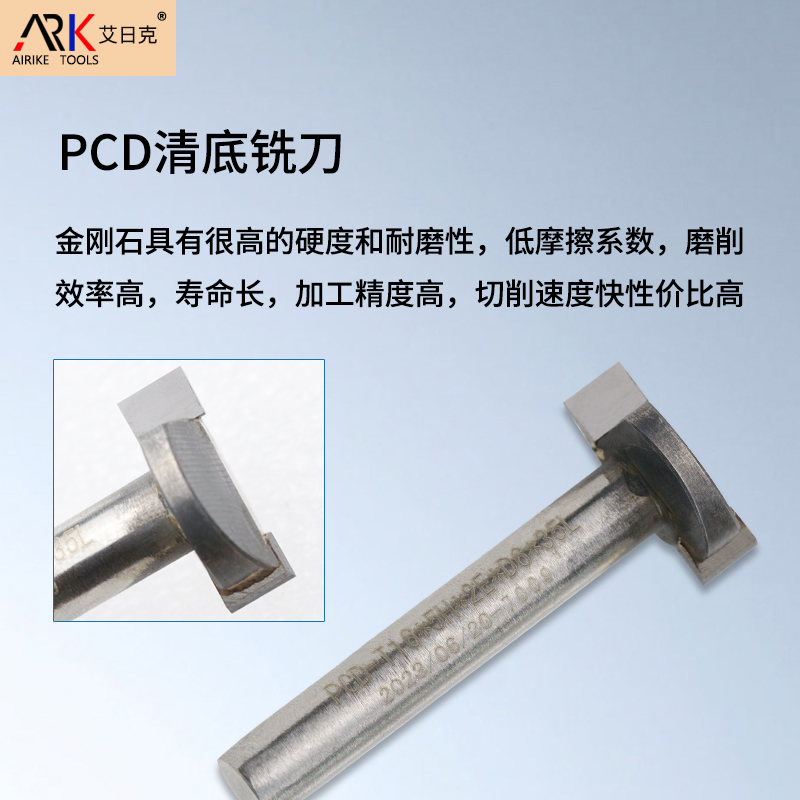

Diamond is mainly divided into two categories: single crystal diamond and polycrystalline diamond. Single crystal diamond is divided into natural single crystal diamond (abbreviated as: ND) and artificial single crystal diamond (abbreviated as: MCD). Polycrystalline diamond is divided into polycrystalline diamond (abbreviated as: PCD) and chemical vapor deposition method (abbreviated as: CVD). So what are the performance advantages of single crystal diamond tools? Let's take a look at it together!

Performance advantages of single crystal diamond tools:

1. Low friction coefficient, small deformation during processing, can reduce cutting force;

2. Single crystal diamond tools have extremely high hardness (10000HV), thus obtaining good wear resistance;

3. The cutting edge of single crystal diamond tools can be sharpened very sharply, and it is not easy to stick the tool and produce built-up edge during cutting, and ultra-thin cutting and ultra-precision processing can be performed;

4. The cutting edge is defect-free under the 800x Nomarski microscope. When processing non-ferrous metals, the surface roughness can reach Rz0.1~0.05μm, and the shape accuracy of the workpiece being processed is controlled below 50nm;

5. The selected single crystal diamond tool particles have good consistency and the service life is 100 times or even hundreds of times that of cemented carbide tools.

The above performance advantages of single crystal diamond tools are shared here for everyone. I hope this article will be helpful to everyone. If you have other questions about diamond milling cutters, you can follow Zhongyeda or leave a message to the editor. We look forward to discussing with you!

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.