Email Us

Zhongyeda Summary: You must know the causes of milling cutter wear!

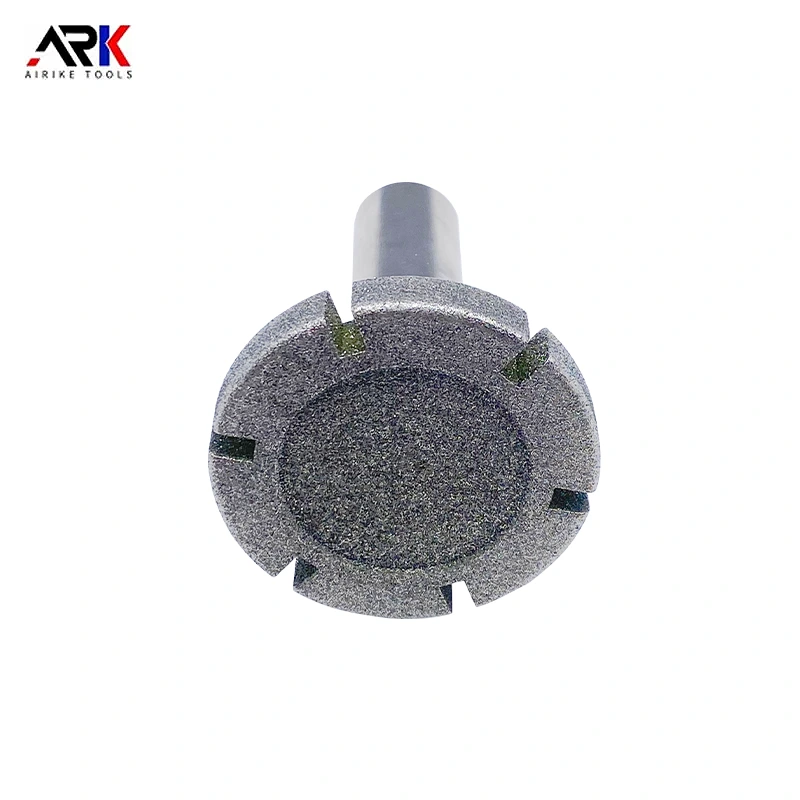

A milling cutter is a cutting tool with a cylindrical shape and cutting edges on the circumference and bottom, which is used to rotate to cut and process workpieces. However, during the use of the milling cutter, wear may occur sometimes. So what are the causes of milling cutter wear? Next, Zhongyeda's editor will introduce this issue to you.

The causes of milling cutter wear are relatively complex, but they can be roughly or mainly divided into two categories:

(1) Mechanical wear: Wear caused by the violent friction between the chip and the front face of the tool, the elastic deformation of the workpiece processing surface and the back face of the tool is called mechanical wear.

When the cutting temperature is not too high, the mechanical scratches caused by this friction are the main cause of tool wear.

(2) Thermal wear: During cutting, due to the violent plastic deformation of the metal and the cutting heat generated by friction, the hardness of the blade is reduced and the cutting performance is lost, which is called thermal wear.

In addition to the above two types of wear, there are the following types of wear:

Under high temperature and high pressure, there will be adhesion between the tool and the workpiece material, and part of the tool material will be carried away by the chips, causing the tool to produce adhesion wear.

At higher temperatures, certain elements in the tool material (such as tungsten, cobalt, titanium, etc.) will diffuse into the workpiece material, thereby changing the chemical composition of the surface layer of the tool cutting part, reducing the tool strength and wear resistance, and causing diffusion wear of the tool.

For high-speed steel tools, at higher cutting temperatures, the metallographic structure of the tool surface will change, reducing the hardness and wear resistance, and phase change wear will occur. Each tooth of the milling cutter is periodically intermittently cut. The temperature of the tooth changes greatly from idle travel to cutting. It can be said that each time it enters cutting, it is subjected to a thermal shock. Under thermal shock, carbide tools will produce great stress inside the blade and cause cracking, resulting in thermal cracking wear of the tool. Since the milling cutter cuts intermittently, the cutting temperature is not as high as that of turning. The main cause of tool wear is generally mechanical wear caused by mechanical friction.

In summary, these are the reasons for the wear of the milling cutter. I hope this article will be helpful to you. If you have other questions about carbon fiber milling cutters, you can follow Zhongyeda or leave a message to the editor. We look forward to discussing with you!

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.