Email Us

What are the characteristics of graphite milling cutters?

Graphite milling cutters are milling cutters that use the high electrical conductivity and good thermal conductivity of graphite materials to quickly dissipate heat during processing. It is widely used in the fields of processing electronics, high-precision machining, and high-strength alloys. So do you know what the characteristics of graphite milling cutters are? The following editor of Zhongyeda will introduce them to you.

The characteristics of graphite milling cutters are mainly reflected in the following aspects:

1. Material selection:

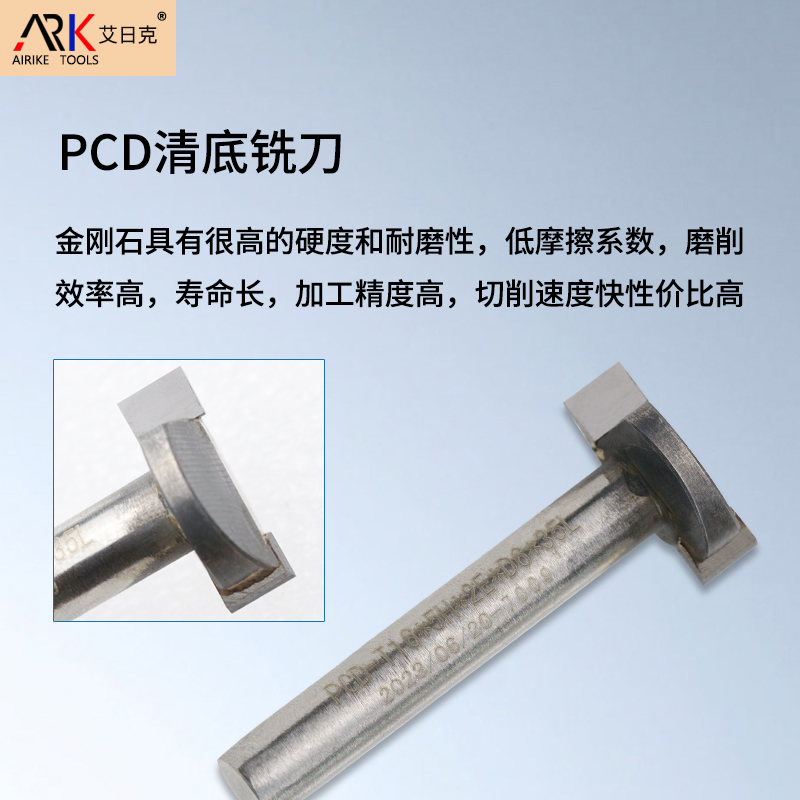

Graphite milling cutters are usually made of diamond coating or cemented carbide to ensure their high hardness and wear resistance. Diamond coating can significantly improve the hardness and wear resistance of the tool and extend its service life.

2. Blade design:

The blade of the graphite milling cutter is specially designed to optimize cutting performance and reduce wear. The geometry and angle of the blade are usually adjusted according to the characteristics of the graphite material and the processing requirements.

3. Efficient cutting:

Graphite milling cutters show excellent cutting performance when processing graphite materials, with high cutting efficiency and can significantly shorten the processing time.

4. Long life: Due to the use of high hardness and wear-resistant materials, the service life of graphite milling cutters is relatively long, which can reduce the number of tool changes and improve production efficiency. 5. High precision: Graphite milling cutters can maintain high precision and stability during the processing process to ensure that the workpiece size and shape that meet the requirements are processed. 6. Strong applicability: Graphite milling cutters are not only suitable for the processing of graphite materials, but also for the processing of alloy non-ferrous materials, composite materials, carbon fiber, glass fiber, etc., showing a wide range of applicability. 7. Thermal management: Graphite milling cutters will generate a certain amount of heat during the processing process, so they usually need to be equipped with an effective cooling system to ensure that the temperature of the tool and the workpiece is controlled within a reasonable range to avoid thermal damage. 8. High cost: Due to the use of high-quality materials and precise manufacturing processes, the cost of graphite milling cutters is relatively high. However, considering its characteristics of efficient cutting and long life, graphite milling cutters can bring significant economic benefits in long-term use. In summary, graphite milling cutters play an important role in the processing of graphite materials with their high hardness, wear resistance, efficient cutting, long life, high precision and wide applicability. When selecting graphite milling cutters, comprehensive consideration should be given to specific processing requirements and material properties to ensure the best processing effect.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.