Email Us

The role of diamond milling cutter

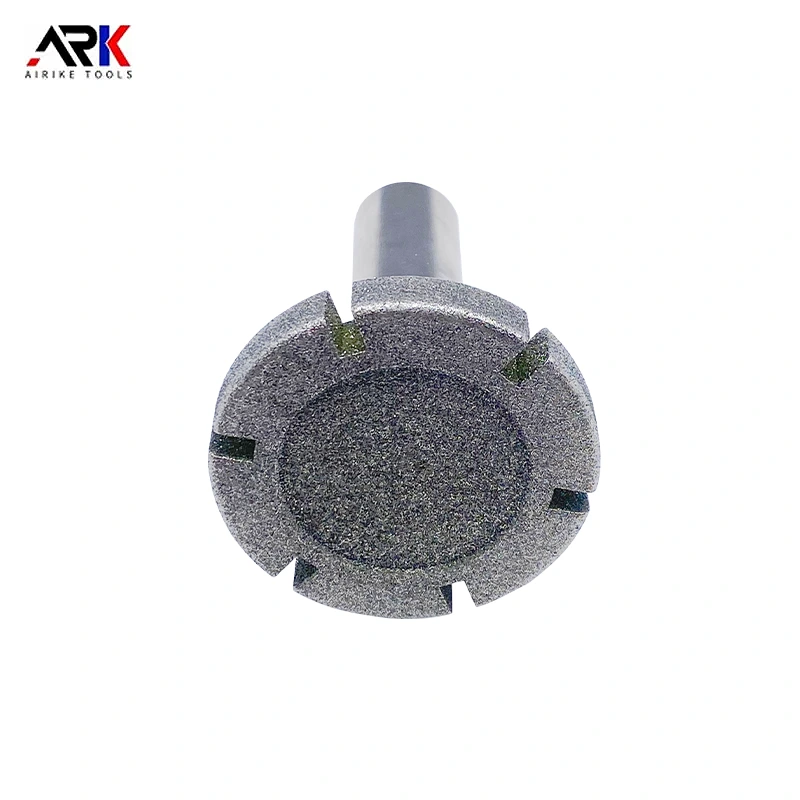

Currently, in the mechanical processing and machine tool industry, diamond is made into milling cutters used on machine tools, which solves the ultra-high surface brightness, smoothness, ultra-high precision, high hardness and other performances and difficult-to-process materials required by some cemented carbide, cubic boron nitride tools, ceramic tools, high-speed steel tools, etc. when processing workpieces.

Diamond milling cutters are therefore called super-hard tools for the machinery manufacturing industry. So what are the functions of diamond milling cutters? The following editor of Zhongyeda will introduce this issue in detail.

The functions of diamond milling cutters are as follows:

1. Improve processing efficiency: Diamond milling cutters have fast and efficient cutting capabilities, can complete a large number of processing tasks in a short time, and improve production efficiency.

2. Improve processing accuracy: Diamond milling cutters have the characteristics of high hardness and high precision, which can ensure the accuracy and surface quality of the processed parts.

3. Increase service life: Diamond milling cutters have a long service life and rarely need to be replaced, which can save costs, and also reduce the damage to machine tools and tools caused by tool change frequency.

The above is just the sharing of the role of diamond milling cutters. In short, diamond milling cutters have been widely used in modern manufacturing. Their high efficiency, precision, wear resistance, and high temperature resistance make them an ideal tool for processing various materials.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.