Email Us

The difference between PCD tools and CBN tools

There are significant differences between PCD tools (polycrystalline diamond tools) and CBN tools (cubic boron nitride tools), which are mainly reflected in the following aspects. The following is a detailed introduction by the editor of Zhongyeda.

1. Raw materials

The raw material of PCD tools is cubic boron nitride (Polycrystalline Cubic Boron Nitride, referred to as PCBN or CBN composite form), which is a synthetic superhard material.

The raw material of CBN tools is diamond, which is also a superhard material, but the chemical composition and crystal structure are different from cubic boron nitride.

2. Chemical stability

PCD tools are easy to react chemically with iron elements at high temperatures, so they are not suitable for processing metals containing iron elements.

CBN tools have strong chemical inertness. Even at high temperatures of 1200~1300 degrees Celsius, they will not react chemically with iron materials. Therefore, they are more suitable for processing ferrous metals, such as gray cast iron, high chromium cast iron, alloy cast iron, hardened steel, high manganese steel, high-speed steel, etc.

3. Scope of application

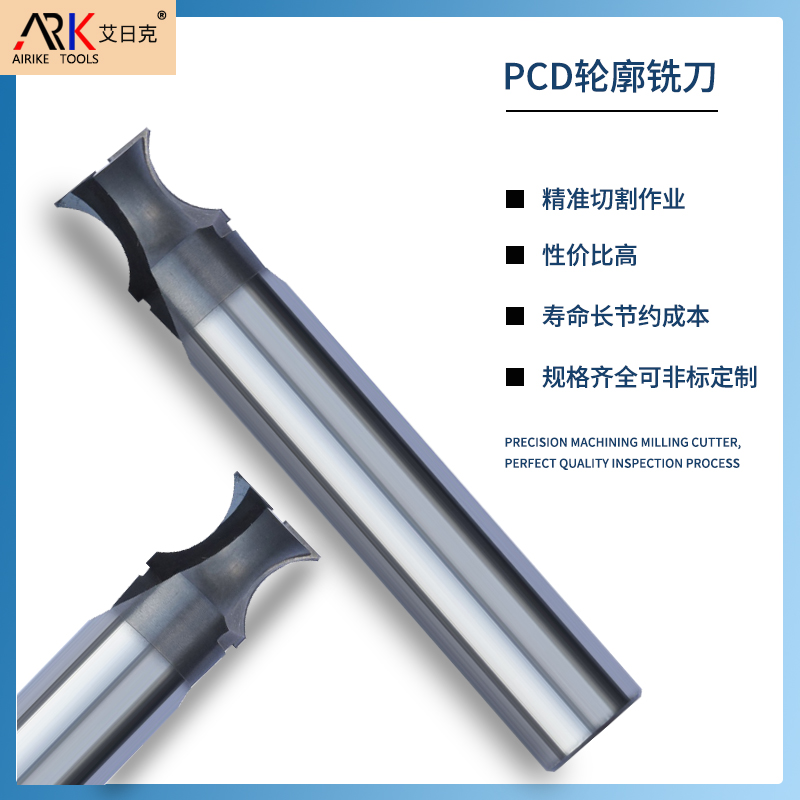

Due to the chemical properties of PCD tools, it is more suitable for processing non-ferrous metals and composite materials, such as aluminum, copper, alloys, carbon fiber composite materials, metal matrix composite materials, etc.

CBN tools are ideal for cutting difficult-to-process materials due to their high hardness and wear resistance, and are widely used in the automotive manufacturing industry, aerospace industry, mold manufacturing industry, bearing industry and other fields.

4. Performance characteristics

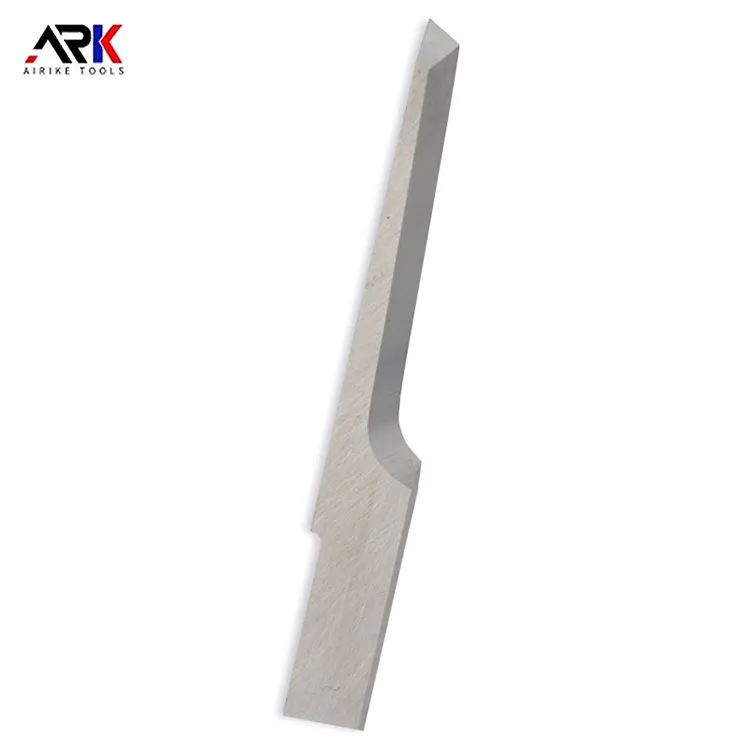

PCD tools have the advantages of high hardness, high heat resistance, high efficiency, sharp chip edge, good thermal conductivity, and long life.

CBN tools also have high hardness, wear resistance and thermal stability, and can maintain hardness and cutting performance under high temperature environment, which is very suitable for high-temperature cutting conditions such as high-speed cutting and dry cutting.

5. Manufacturing process

Both PCD and CBN tools are new superhard composite material processing tools developed in the 1970s. The manufacturing process is relatively complex, including multiple processing procedures such as cutting of the base, grinding of the tool head, welding, and grinding after welding.

In summary, PCD tools and CBN tools have significant differences in raw materials, chemical stability, application range, performance characteristics and manufacturing process. Therefore, when choosing tools, reasonable selection should be made according to specific processing materials and process requirements.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.