Email Us

Properties and characteristics of chamfering cutters

Chamfering cutters are tools used on milling machines, drilling machines, planing machines, chamfering machines and other machine tools to process 60-degree or 90-degree chamfers and tapered holes of workpieces, and chamfer edges. They belong to end mills. So what are the properties and characteristics of chamfering cutters? Let's take a look at them together!

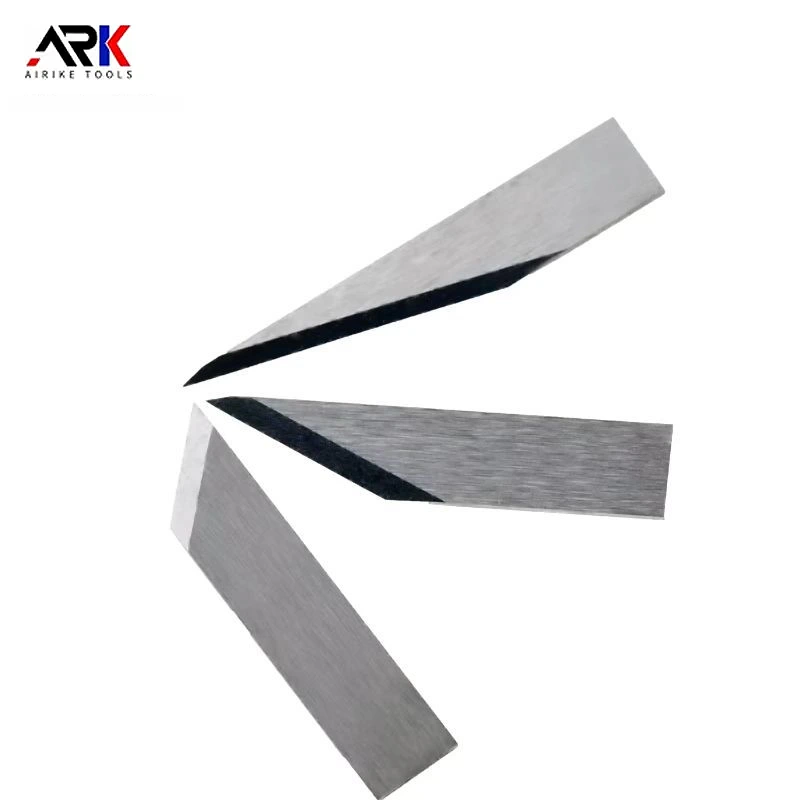

Properties and characteristics of chamfering cutters: Specifications: three-edged, single-edged. Angles: 90 degrees, 60 degrees, other angles are non-standard and need to be customized.

Specifications: ¢4-¢80. Purpose: Used for 60°, 90° chamfers or tapered holes of workpiece circular holes, and chamfering of edges and corners of various surfaces.

Features: The processing of the conical surface can be completed in one go. Suitable for small cutting amount processing.

Material: HSS, high-speed steel. The above-mentioned properties and characteristics of chamfering cutters are shared here.

Chamfering cutters have a wide range of applications. They are not only suitable for chamfering of ordinary machined parts, but also for chamfering and deburring of precision and difficult chamfered parts.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.