Industry News

06 2025-11

06 2025-11 What Makes Stone Carving Milling Cutters the Future of Precision Stone Processing?

Stone carving has evolved from manual craftsmanship into an advanced precision engineering process. At the core of this transformation lies the Stone Carving Milling Cutter, a high-performance tool specifically designed for cutting, engraving, shaping, and polishing various types of natural and artificial stones. These cutters are engineered with industrial-grade tungsten carbide or diamond coatings, ensuring exceptional durability, speed, and accuracy when working with materials such as granite, marble, sandstone, and quartz.

29 2025-10

29 2025-10 What are the rotational speed and feed rate of a welding milling cutter?

In metalworking, welding milling cutters are commonly used tools. Proper selection of their rotational speed and feed rate directly impacts work efficiency, part quality, and tool life.

24 2025-10

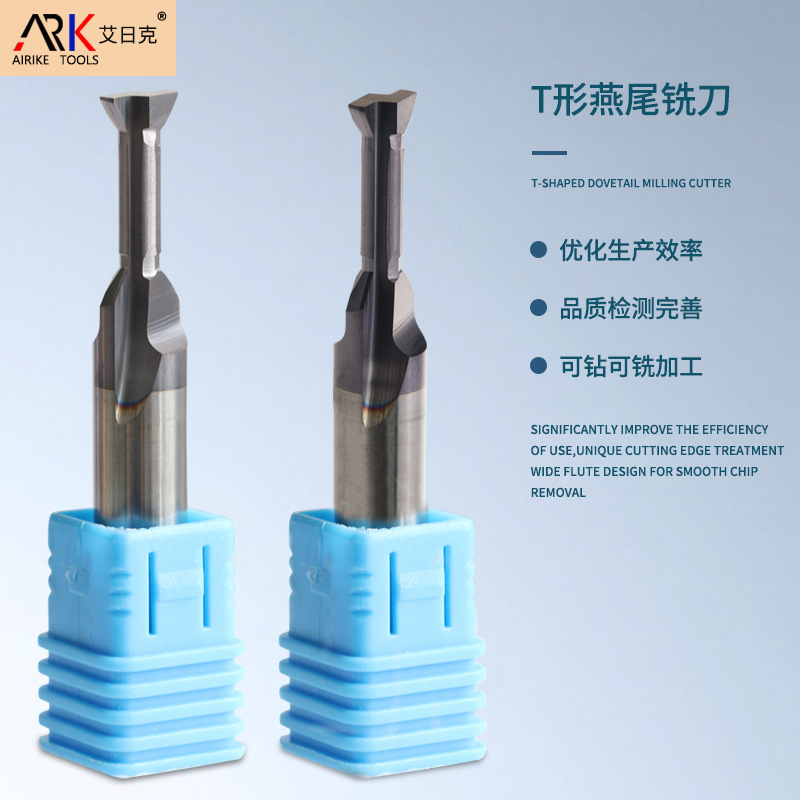

24 2025-10 How to Align a T-Slot Cutter?

The T-slot cutter, also known as a T-slot milling cutter or semi-circular milling cutter, is a critical tool for machining T-slots and side grooves. Widely used in mold manufacturing and mechanical processing, proper alignment is essential for ensuring machining accuracy and efficiency.

23 2025-10

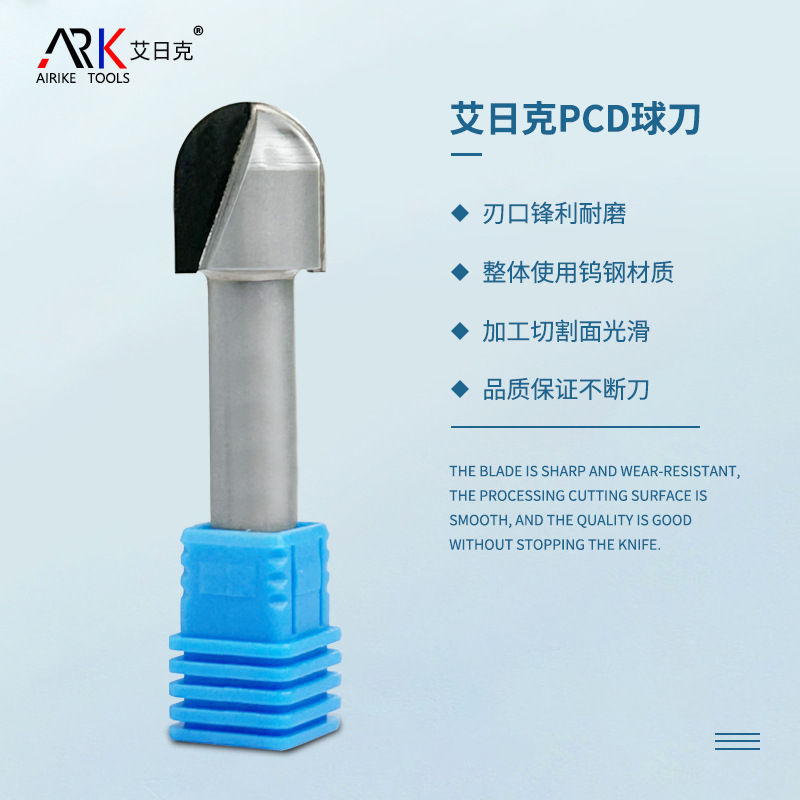

23 2025-10 What Is a Diamond Milling Cutter and How Does It Enhance Machining Efficiency?

Diamond Milling Cutters are precision cutting tools designed with polycrystalline diamond (PCD) edges, enabling high-speed, high-accuracy material removal. These tools are widely used in aerospace, automotive, mold-making, and wood, plastics, and non-ferrous metals machining industries. Unlike conventional carbide cutters, diamond milling cutters provide superior wear resistance, reduce cutting forces, and deliver smooth surface finishes.

11 2025-10

11 2025-10 How to maintain the graphite milling cutter?

Good maintenance not only extends the life of the cutting tool, but also ensures machining accuracy and surface quality. So how much do you know about the maintenance of graphite milling cutter?

11 2025-10

11 2025-10 Why choose alf-Cutting Cutter?

In the evolving world of precision machining, the Half-Cutting Cutter has emerged as a crucial innovation that bridges accuracy, durability, and speed. It is widely used in manufacturing processes where precise depth control and clean cutting edges are essential — such as in die-cutting, flexible printed circuits (FPCs), adhesive materials, and thin films. The name “half-cutting” refers to its ability to cut through material layers without penetrating the entire substrate, leaving the backing layer intact. This functionality allows for improved product integrity, faster processing times, and minimal waste — making it indispensable for industries that rely on micro-fabrication and fine material processing.