Email Us

How to Align a T-Slot Cutter?

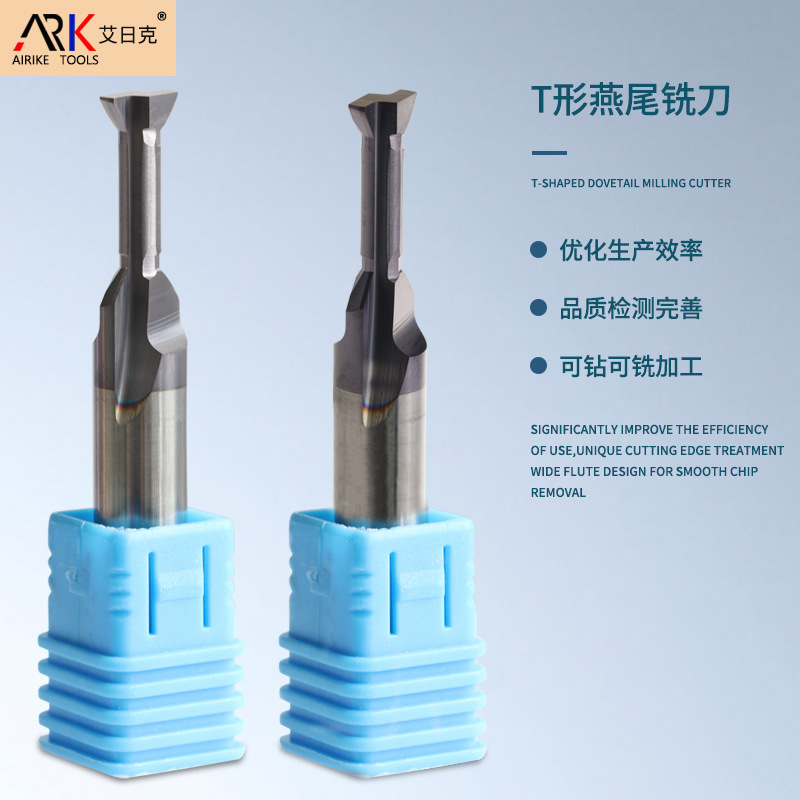

The T-slot cutter, also known as a T-slot milling cutter or semi-circular milling cutter, is a critical tool for machining T-slots and side grooves. Widely used in mold manufacturing and mechanical processing, proper alignment is essential for ensuring machining accuracy and efficiency. So, do you know how to align a T-slot cutter?

The specific method is as follows:

I. Preparations Before Alignment

Check the accuracy and stability of the machine tool spindle to prevent loosening or wobbling. Clean the tool and fixture, removing oil and contaminants. Prepare auxiliary tools such as a tool presetter, dial indicator, and gauge blocks to lay the foundation for precise tool setting.

II. Basic Tool Setting Steps

First, install the tool. Securely mount the T-slot cutter on the spindle to prevent loosening during machining.

Second, tool alignment: Adjust the tool position using a dial indicator or tool setting device to align it with the workpiece machining reference—this is the critical step in tool setting.

Third, tool height setting: Determine the cutting depth according to machining requirements to ensure the groove depth meets the drawing specifications.

III. Tool Setting Techniques for Different Scenarios

For standard T-slot machining, use the direct tool setting method, determining the position through visual inspection and simple measurement. High-precision keyway machining requires precision tool setting using a tool presetter or dial indicator. Software like UG can simulate tool paths for preset milling from bottom-up, accommodating complex groove machining to enhance efficiency and accuracy.

IV. Precautions

Always ensure secure tool clamping to prevent quality or safety issues from loosening. Perform tool setting gently to avoid damaging tools or workpieces. Maintain a clean tool setting environment. For high-precision machining, perform operations in a temperature-controlled environment to minimize thermal effects on accuracy.

Overall, tool setting for T-slot cutters is a highly technical task requiring operators to possess extensive professional knowledge and practical experience.

By mastering correct tool setting methods and techniques, we believe you can effectively enhance machining quality and efficiency, extend tool life, and generate greater economic benefits for your enterprise.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.