Email Us

Why choose alf-Cutting Cutter?

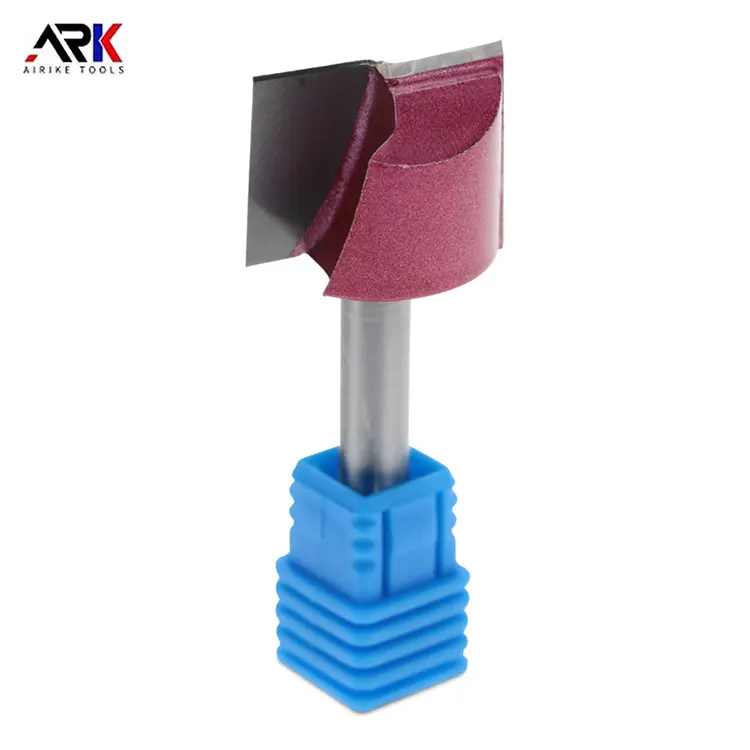

In the evolving world of precision machining, Half-Cutting Cutter has emerged as a crucial innovation that bridges accuracy, durability, and speed. It is widely used in manufacturing processes where precise depth control and clean cutting edges are essential — such as in die-cutting, flexible printed circuits (FPCs), adhesive materials, and thin films. The name “half-cutting” refers to its ability to cut through material layers without penetrating the entire substrate, leaving the backing layer intact. This functionality allows for improved product integrity, faster processing times, and minimal waste — making it indispensable for industries that rely on micro-fabrication and fine material processing.

The primary function of a Half-Cutting Cutter is to achieve precision-controlled depth cutting, which ensures that materials such as laminates, labels, tapes, and electronic films maintain their structural stability during separation or assembly. The tool design focuses on balancing sharpness with rigidity, allowing it to cut only the required surface layer while preserving the base material beneath.

In today’s high-demand manufacturing sectors — from electronics and automotive to packaging — accuracy is no longer optional. The Half-Cutting Cutter answers the global call for ultra-precise and consistent cutting technology that enhances both product performance and operational efficiency.

Below is a technical parameter summary that highlights the standard specifications of Half-Cutting Cutters used across industries:

| Parameter | Specification | Description |

|---|---|---|

| Material | Tungsten Carbide / High-Speed Steel (HSS) | Ensures long tool life, resistance to wear and heat. |

| Coating | TiN, TiAlN, or DLC (Diamond-Like Carbon) | Reduces friction, enhances surface hardness, and prevents chip adhesion. |

| Cutting Edge Angle | 15° – 45° | Optimized for precise depth and smooth cutting. |

| Cutting Depth Accuracy | ±0.005 mm | Guarantees consistent layer control during processing. |

| Applicable Materials | PET, PVC, Polyimide, Copper Foil, Adhesive Films | Suitable for electronics, packaging, and label industries. |

| Tool Diameter Range | 0.5 mm – 6.0 mm | Available in multiple configurations for various machine types. |

| Shank Type | Straight / Tapered | Designed to fit high-speed CNC and precision cutting systems. |

| Usage | Die-cutting, Kiss-cutting, Micro-depth Engraving | Ideal for FPC manufacturing and adhesive material processing. |

This table underscores the cutter’s versatility and high performance across diverse applications. Manufacturers often choose Half-Cutting Cutters for their ability to enhance productivity while maintaining dimensional accuracy even under high-speed machining conditions.

Why Half-Cutting Cutters Are the Key to Next-Generation Manufacturing

As industries increasingly demand high precision and material optimization, the Half-Cutting Cutter has become the centerpiece of modern fabrication systems. Its growing importance stems from several key advantages that go beyond conventional cutting technologies.

1. Enhanced Precision and Control

Half-Cutting Cutters are designed for ultra-fine material removal, maintaining a perfectly controlled depth that allows partial penetration of the workpiece. This accuracy reduces errors in production lines and eliminates the need for additional finishing steps, significantly shortening manufacturing cycles.

2. Material Preservation and Waste Reduction

By cutting only the surface layer, the Half-Cutting Cutter minimizes waste material and preserves the structural integrity of the remaining substrate. This is particularly important in environmentally conscious industries where material conservation is a corporate priority.

3. Superior Edge Quality

The sharp geometry and high-quality coatings of modern Half-Cutting Cutters create clean, burr-free edges that are ideal for high-end products such as electronic components, optical films, and custom adhesive tapes. This enhances final product aesthetics and functionality.

4. Compatibility with Automated Systems

Automation is redefining industrial efficiency. Half-Cutting Cutters are engineered to operate seamlessly with CNC, laser-assisted, and robotic machining systems. Their consistency and reliability make them ideal for integration into smart factories and Industry 4.0 environments.

5. Extended Tool Life

Advanced coating technologies like TiAlN and DLC dramatically reduce tool wear and heat generation, enabling longer continuous operation. This translates into lower tool replacement costs and higher throughput — a vital factor for large-scale manufacturers.

6. Adaptability to Diverse Materials

From polymer films to metallic laminates, Half-Cutting Cutters perform with exceptional uniformity. Their geometry can be customized based on specific cutting depth requirements, material hardness, and production line speed.

In essence, the Half-Cutting Cutter is not merely a tool — it’s a precision solution that drives manufacturing efficiency, sustainability, and innovation.

How Half-Cutting Cutters Are Shaping Future Manufacturing Trends

The future of machining and fabrication relies on smarter tools capable of integrating with digital and automated systems. Half-Cutting Cutters are already aligning with these trends in several transformative ways:

A. Integration with Smart Machining Systems

Manufacturers are now coupling Half-Cutting Cutters with intelligent CNC software capable of auto-calibrating cutting depth and speed in real time. This ensures consistent accuracy, even when switching between materials of varying thicknesses.

B. Advanced Coating Technologies

Innovations in nanocomposite coatings are further enhancing cutter longevity and performance. Future Half-Cutting Cutters will feature adaptive coatings that respond dynamically to cutting temperatures and friction, ensuring uniform edge quality across extended production runs.

C. Micro-Manufacturing and Flexible Electronics

As the electronics industry shifts toward flexible devices and thinner materials, the need for cutters that can execute micro-level precision continues to grow. Half-Cutting Cutters will play a central role in producing flexible printed circuits, wearable sensors, and advanced microchips.

D. Sustainability and Material Efficiency

With global initiatives emphasizing eco-friendly manufacturing, tools like the Half-Cutting Cutter contribute to waste minimization and energy efficiency. Precision cutting ensures less scrap, optimized resource use, and reduced carbon emissions.

E. Customization and AI-Driven Design Optimization

While traditional cutting tools are static, future Half-Cutting Cutters are expected to leverage computational modeling and AI-based geometry design to create custom tool paths and blade shapes tailored to specific materials or processes.

The combination of smart technology, material science, and sustainability positions Half-Cutting Cutters as an integral component of the future industrial ecosystem — where accuracy, speed, and responsibility converge.

Common Questions About Half-Cutting Cutters

Q1: What is the difference between a Half-Cutting Cutter and a Full-Cutting Cutter?

A Half-Cutting Cutter performs partial-depth cutting, meaning it only penetrates the surface layer of a material while leaving the base layer intact. This technique is essential for applications like label cutting or FPC manufacturing, where precision layer separation is necessary. A Full-Cutting Cutter, in contrast, slices through the entire material thickness, which may not be suitable for processes requiring controlled depth.

Q2: How can the lifespan of a Half-Cutting Cutter be maximized?

The lifespan depends on several operational factors, including cutting speed, material type, and cooling method. Using proper lubrication, maintaining consistent cutting speeds, and choosing cutters with advanced coatings (such as TiAlN or DLC) can extend tool life significantly. Regular inspection for wear and micro-chipping also ensures consistent performance and prevents costly downtime.

In a rapidly changing industrial landscape, the Half-Cutting Cutter stands as a symbol of precision engineering and sustainable manufacturing. Its ability to deliver clean, controlled, and repeatable cuts not only increases productivity but also helps manufacturers reduce waste and achieve superior product quality. From flexible circuit fabrication to high-speed label production, this tool’s versatility underscores its role in shaping the next era of high-precision industries.

Zhongyeda, a leading manufacturer specializing in precision cutting tools, continues to push the boundaries of performance and reliability in Half-Cutting Cutter technology. By combining cutting-edge materials, meticulous craftsmanship, and strict quality control, Zhongyeda ensures every cutter meets the exacting standards of global industries.

For technical consultation, custom specifications, or bulk orders of Half-Cutting Cutters, contact us to discover how Zhongyeda can enhance your production capabilities with precision tools designed for the future.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.