Email Us

What Makes Stone Carving Milling Cutters the Future of Precision Stone Processing?

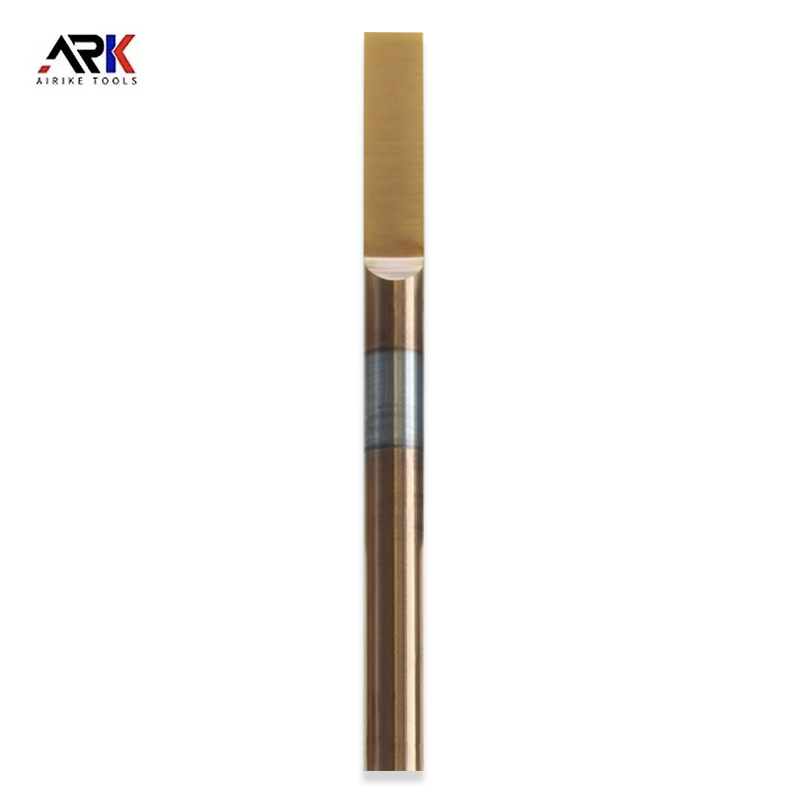

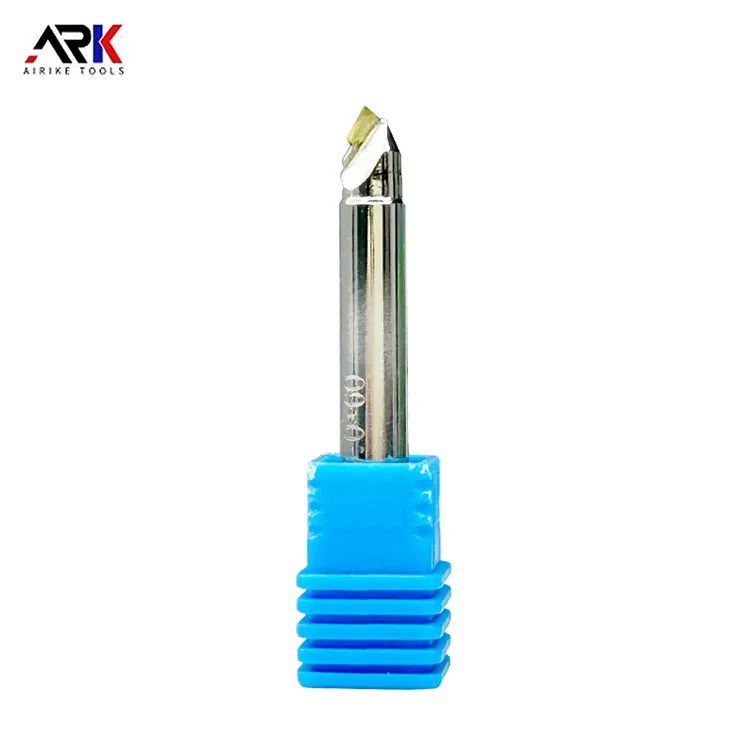

Stone carving has evolved from manual craftsmanship into an advanced precision engineering process. At the core of this transformation lies the Stone Carving Milling Cutter, a high-performance tool specifically designed for cutting, engraving, shaping, and polishing various types of natural and artificial stones. These cutters are engineered with industrial-grade tungsten carbide or diamond coatings, ensuring exceptional durability, speed, and accuracy when working with materials such as granite, marble, sandstone, and quartz.

Unlike traditional hand-carving tools, Stone Carving Milling Cutters operate with CNC machines, allowing automated control and precise detailing on complex stone surfaces. The innovation of milling technology not only enhances production efficiency but also significantly improves the consistency and intricacy of carved designs.

But what makes these tools indispensable in modern stone fabrication industries? The answer lies in their precision, endurance, and adaptability. As architectural design, monument production, and decorative art industries increasingly rely on complex stone detailing, the demand for professional-grade milling cutters continues to grow.

Below is a detailed overview of product specifications and technical features that demonstrate their versatility and performance.

| Parameter | Specification |

|---|---|

| Material | Tungsten Carbide / Diamond Coated Alloy |

| Shank Diameter | 6mm / 8mm / 10mm (custom sizes available) |

| Cutting Edge Diameter | 3mm–20mm |

| Overall Length | 50mm–100mm |

| Applicable Materials | Granite, Marble, Quartz, Sandstone, Artificial Stone |

| Surface Coating | Nano Diamond / Titanium Nitride |

| Cutting Type | Dry or Wet Milling |

| Tool Type | Ball Nose, Flat End, Tapered, V-Shaped, Engraving Bits |

| Tolerance | ±0.02mm |

| Usage | CNC Stone Router Machines, Engraving Centers, and 3D Carving Systems |

These specifications reveal how advanced engineering ensures a balance between tool rigidity and flexibility. Whether used in high-speed carving for artistic sculptures or for industrial-grade engraving, Stone Carving Milling Cutters deliver a refined edge finish and prolonged service life under demanding conditions.

Why Stone Carving Milling Cutters Are Revolutionizing Modern Stone Processing

Why are these cutters so essential for modern stone industries?

The fundamental reason is efficiency and precision. Traditional carving tools require manual effort and are limited in detail control. In contrast, CNC-compatible milling cutters can execute intricate patterns and smooth finishes within minutes. The adoption of these cutters reduces production time by up to 70% while maintaining consistent surface quality.

Key Advantages:

-

Superior Precision:

The geometrical accuracy of these cutters enables perfect contouring, engraving, and fine detailing without surface chipping or cracks. -

Enhanced Durability:

With diamond or tungsten carbide coatings, they resist wear even under intense cutting pressure, ensuring long operational life. -

Heat Resistance:

Specialized coatings provide thermal stability, minimizing deformation or micro-cracking during extended operation. -

Versatile Applications:

Ideal for use in artistic sculpture, architectural cladding, tombstone engraving, monument carving, and decorative pattern creation. -

Reduced Maintenance Costs:

The high-strength tool body and coating significantly decrease tool replacement frequency and machine downtime.

Moreover, the integration of digital control technology has expanded the potential of milling cutters beyond traditional sculpting. Advanced CAD/CAM software allows engineers and artists to create digital designs that can be translated into flawless three-dimensional carvings with micrometer precision. This seamless link between design and production forms the backbone of Industry 4.0 in stone manufacturing.

In today’s competitive global market, where demand for aesthetic architectural details and custom art pieces is rising, Stone Carving Milling Cutters represent a turning point in achieving superior results with minimal waste. They embody the future of high-efficiency, precision-oriented stone processing.

How to Choose the Right Stone Carving Milling Cutter for Your Application

Selecting the right Stone Carving Milling Cutter depends on several technical factors such as material hardness, carving depth, desired finish, and machine type. Understanding these parameters helps ensure optimal performance and extended tool life.

Key Selection Factors:

-

Stone Type:

-

For granite and quartz, use diamond-coated cutters for maximum durability and cutting strength.

-

For marble and sandstone, tungsten carbide tools are sufficient for smooth and clean edges.

-

-

Cutting Depth and Diameter:

-

Deep carving requires longer tools with stable rigidity.

-

Shallow engraving benefits from short, fine-tipped cutters for precision.

-

-

Feed Rate and Spindle Speed:

-

Lower feed rates ensure accuracy on hard stones.

-

Adjust spindle speeds based on stone density and cutter geometry.

-

-

Cooling Method:

-

Wet milling is recommended for extended tool life and improved finish quality.

-

Dry milling should only be used when water cooling is not feasible.

-

-

Coating Type:

-

Nano diamond coatings provide high friction resistance and smoother surface output.

-

Titanium nitride coatings are ideal for moderate hardness stones and extended performance.

-

Maintenance Tips:

-

Always clean the tool after each use to prevent stone dust accumulation.

-

Check the cutting edge regularly for wear and replace before it dulls to prevent tool breakage.

-

Ensure correct tool holder alignment to minimize vibration and ensure consistent accuracy.

The correct application and maintenance of the milling cutter not only preserve tool longevity but also protect the CNC spindle and maintain production stability.

Future Trends and Market Outlook for Stone Carving Milling Cutters

The future of stone carving tools lies in innovation and sustainability. As industries move toward smart manufacturing, AI-assisted CNC systems and automated toolpath optimization are transforming how milling cutters are used. Future developments will emphasize advanced coating technologies, self-lubricating materials, and eco-friendly production processes.

Emerging Trends:

-

Smart Tool Recognition: Integration of RFID chips in milling cutters for automatic tool data recognition and CNC synchronization.

-

Nano-Composite Coatings: Enhanced resistance to heat and abrasion, extending the tool’s service life.

-

Hybrid Machining Systems: Combination of laser and milling for ultra-fine detailing on hard stone surfaces.

-

Sustainability Focus: Reduction in waste materials and energy-efficient machining through optimized tool geometry.

The market demand for Stone Carving Milling Cutters continues to rise globally, driven by the expansion of construction, memorial art, and luxury décor industries. Manufacturers and artisans are now prioritizing tools that deliver both artistic finesse and industrial reliability.

Common Questions About Stone Carving Milling Cutters

Q1: How long does a Stone Carving Milling Cutter typically last?

A high-quality diamond-coated cutter can last for hundreds of carving hours, depending on stone hardness, spindle speed, and maintenance. Regular cleaning and proper cooling can extend its lifespan significantly.

Q2: Can the same cutter be used for both marble and granite?

While some universal cutters exist, it is advisable to use specific tools tailored to each stone type. Granite requires diamond-coated cutters due to its high density, whereas marble can be efficiently processed with tungsten carbide tools for smoother finishes.

The Future Belongs to Precision and Innovation

In the evolving world of stone processing, Stone Carving Milling Cutters stand as a testament to engineering excellence and technological evolution. They enable industries to achieve precise, artistic, and durable stonework at unmatched efficiency. With continuous advancements in tool design, coating materials, and CNC integration, these cutters are shaping the future of architectural art and precision manufacturing.

As a trusted name in high-performance cutting tools, Zhongye Da remains dedicated to providing professional-grade milling cutters that combine innovation, durability, and precision. For further inquiries or customized solutions for stone processing applications, contact us today to discover how advanced cutter technology can elevate your production quality and efficiency.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.