News

We are pleased to share with you the outcomes of our work, company news, and keep you updated on timely developments as well as the latest personnel appointments and departures.

06 2025-11

06 2025-11 What Makes Stone Carving Milling Cutters the Future of Precision Stone Processing?

Stone carving has evolved from manual craftsmanship into an advanced precision engineering process. At the core of this transformation lies the Stone Carving Milling Cutter, a high-performance tool specifically designed for cutting, engraving, shaping, and polishing various types of natural and artificial stones. These cutters are engineered with industrial-grade tungsten carbide or diamond coatings, ensuring exceptional durability, speed, and accuracy when working with materials such as granite, marble, sandstone, and quartz.

29 2025-10

29 2025-10 What are the rotational speed and feed rate of a welding milling cutter?

In metalworking, welding milling cutters are commonly used tools. Proper selection of their rotational speed and feed rate directly impacts work efficiency, part quality, and tool life.

24 2025-10

24 2025-10 How to Scientifically Determine the Milling Depth for Woodworking Milling Cutters?

In woodworking milling, setting the cutting depth is critical for influencing machining quality, tool life, and operational safety. Too shallow requires repeated processing, reducing efficiency, while too deep can lead to tool overload, workpiece tearing, or even equipment damage. Therefore, selecting the appropriate cutting depth for woodworking milling cutters is an essential skill for woodworkers.

24 2025-10

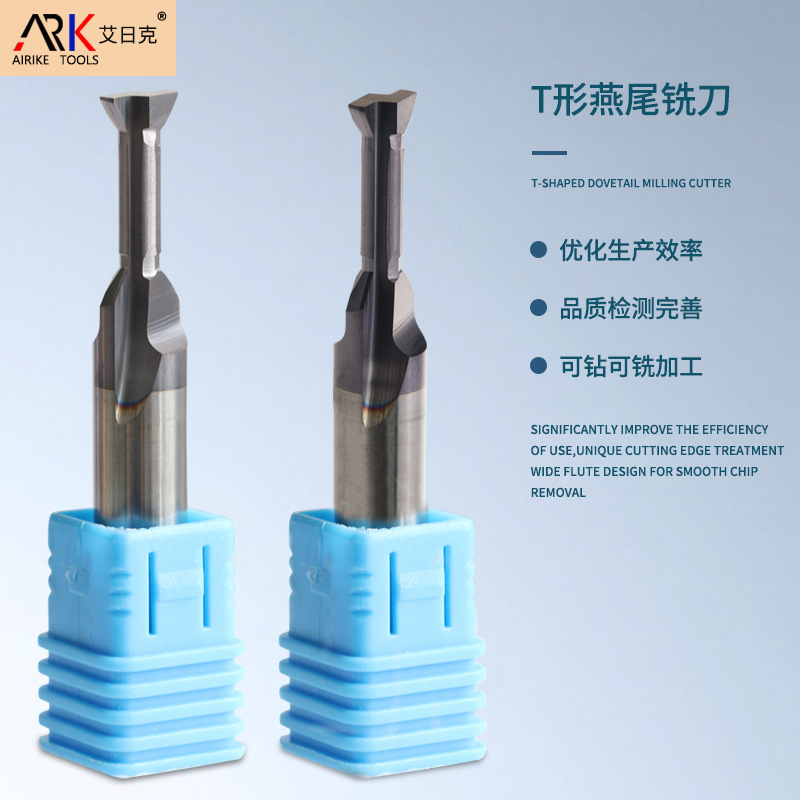

24 2025-10 How to Align a T-Slot Cutter?

The T-slot cutter, also known as a T-slot milling cutter or semi-circular milling cutter, is a critical tool for machining T-slots and side grooves. Widely used in mold manufacturing and mechanical processing, proper alignment is essential for ensuring machining accuracy and efficiency.

23 2025-10

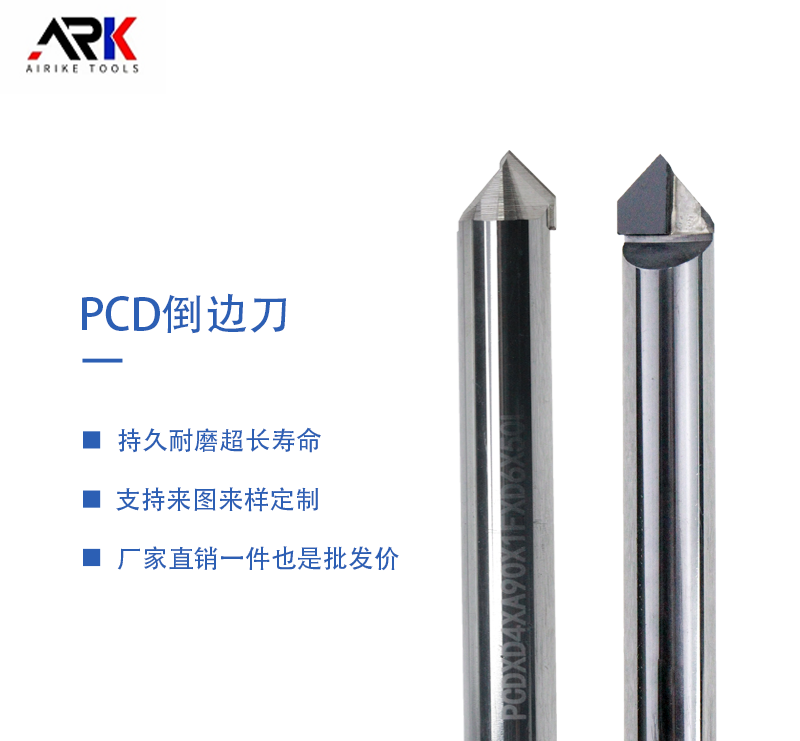

23 2025-10 What Is a Diamond Milling Cutter and How Does It Enhance Machining Efficiency?

Diamond Milling Cutters are precision cutting tools designed with polycrystalline diamond (PCD) edges, enabling high-speed, high-accuracy material removal. These tools are widely used in aerospace, automotive, mold-making, and wood, plastics, and non-ferrous metals machining industries. Unlike conventional carbide cutters, diamond milling cutters provide superior wear resistance, reduce cutting forces, and deliver smooth surface finishes.

15 2025-10

15 2025-10 Metal cutting process inventory, which method of machining is more applicable?

In the field of machining, metal cutting is the most basic and most commonly used to a process, metal cutting processing is divided into many kinds, there are turning, drilling, boring, planing, broaching, milling and grinding.