Email Us

How to Scientifically Determine the Milling Depth for Woodworking Milling Cutters?

In woodworking milling, setting the cutting depth is critical for influencing machining quality, tool life, and operational safety. Too shallow requires repeated processing, reducing efficiency, while too deep can lead to tool overload, workpiece tearing, or even equipment damage.

Therefore, selecting the appropriate cutting depth for woodworking milling cutters is an essential skill for woodworkers. How should it be chosen?

Zhongyeda recommends the following approach:

I. Prioritize Manufacturer Specifications

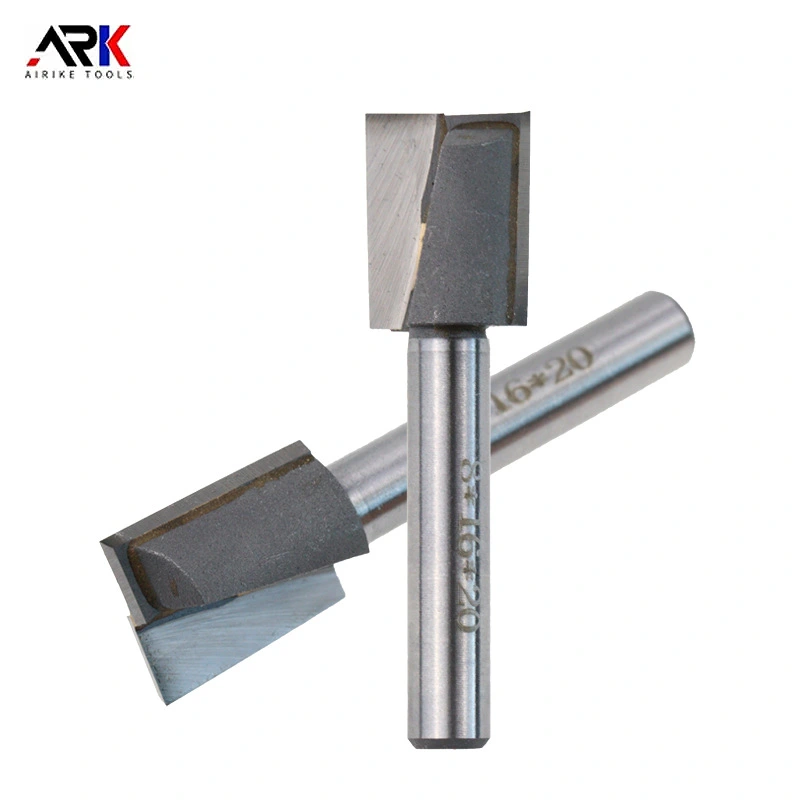

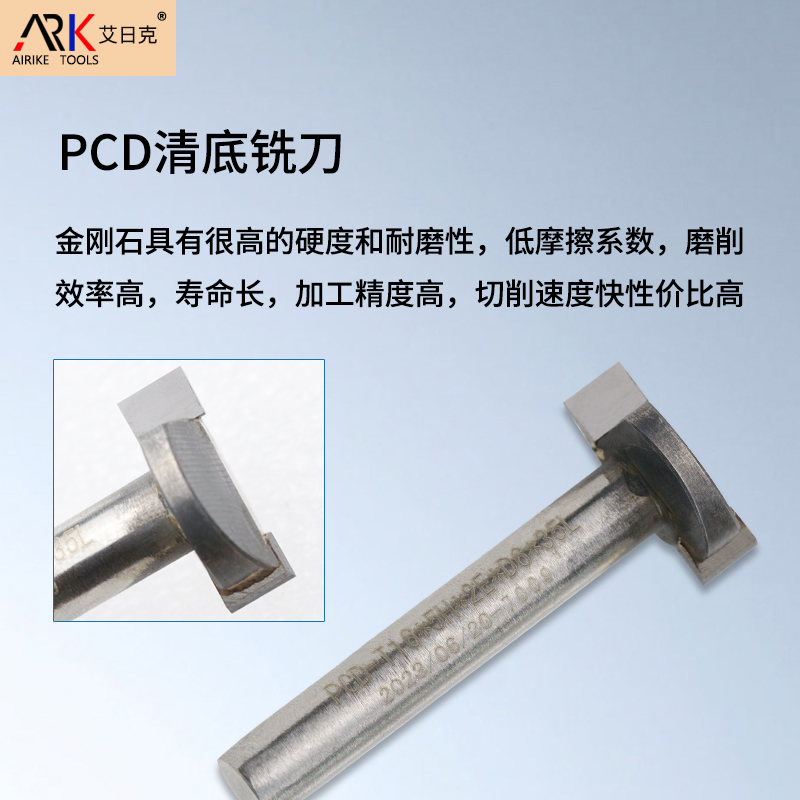

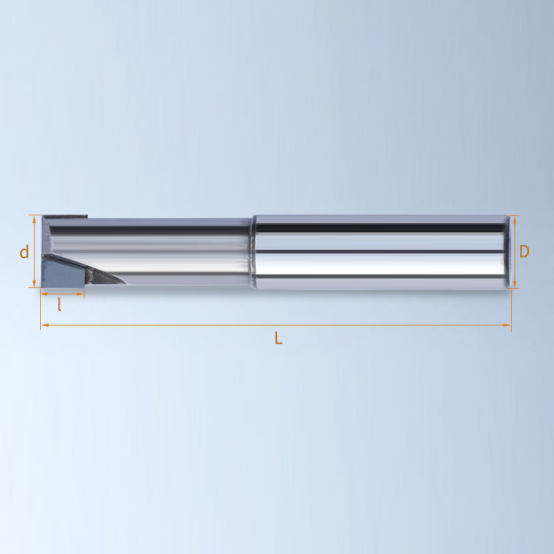

Different brands and models of Woodworking Milling Cutters come with recommended cutting parameters. Before selecting a depth, carefully consult the tool manual or follow the manufacturer's guidelines. This provides the most direct scientific basis and avoids issues caused by arbitrary settings.

II. Determine Optimal Depth Through Trial Cutting and Adjustment

Before actual machining, gradually adjust the depth via trial cuts: Start with a shallow depth, observe the machining results and tool condition, then fine-tune as needed until suitable parameters are found. Trial cutting is especially crucial for new wood types or complex workpieces to ensure machining quality.

III. Plan Depth in Conjunction with Tool Maintenance

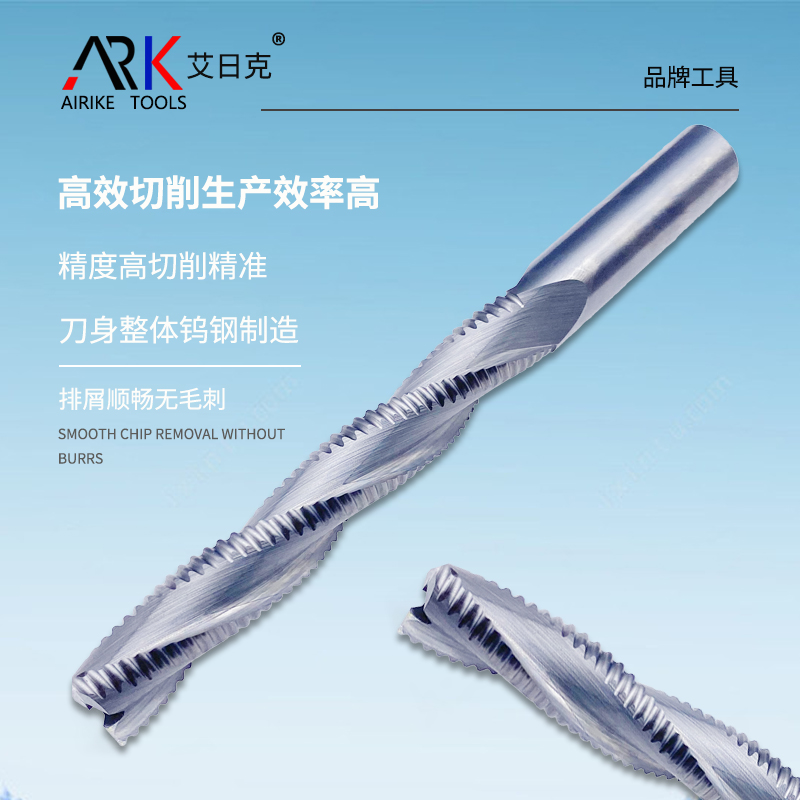

Greater milling depth accelerates tool wear. When selecting depth, simultaneously consider tool consumption. Regularly inspect cutting edge wear and promptly replace or regrind tools. This maintains machining precision while extending tool life through optimal depth selection.

IV. Align Depth with Safety Protections

Deep cuts generate higher cutting forces and noise. Safety must be prioritized when setting depth: Operators must wear protective gear, ensure workpieces are securely clamped, and prevent accidents caused by vibration or flying chips. This ensures depth selection and safety measures are implemented simultaneously.

In summary, scientifically selecting the milling depth for Woodworking Milling Cutters requires balancing factors such as material, tooling, and equipment. Through accumulated experience and experimental optimization, both machining quality and efficiency can be enhanced.

- The same milling cutter, the market phenomenon of milling cutter price difference

- Korean customers visited our company to discuss a new chapter of milling cutter cooperation!

- Using the wrong cutting fluid is like throwing away money on milling cutters?

- Zongyeda Explains - Clockwise or Counterclockwise Rotation for Woodworking Milling Cutters?

- Zhongyeda - What's the Difference Between Chamfering Tools and Centering Drills?

- Metal cutting process inventory, which method of machining is more applicable?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.