Email Us

What is plunge milling? What are its applications in machining?

In the field of mechanical machining, milling is a common metal cutting method, and plunge milling, as a special milling process, is increasingly gaining attention in high-efficiency machining. So, what exactly is plunge milling? What are its unique applications and advantages in machining? Let's take a look with the Zhongye da editor.

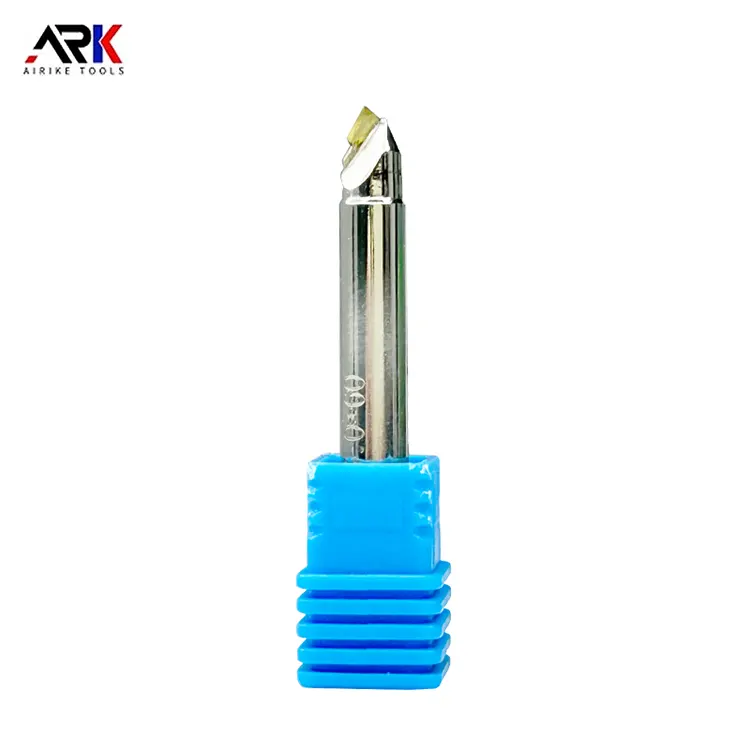

Plunge milling, also known as axial milling or straight plunge milling, is a machining method in which the milling cutter cuts directly into the workpiece along the axial direction. Unlike traditional side milling, the cutting force is mainly along the axis of the cutting tool rather than radially, which gives it significant advantages in machining deep grooves, cavities, difficult-to-cut materials, and large stock removal.

Plunge milling usually uses a special plunge milling cutter or a long-edge end mill. The cutting tool rotates at high speed while moving up and down along the Z-axis, removing material layer by layer, similar to a combination of “drilling + milling.”

A. It has a wide range of applications and performs particularly well in the following processing scenarios

(1) Deep cavity/deep groove processing: Traditional milling is prone to vibration due to the long overhang of the cutting tool when processing deep cavities, which affects processing accuracy and tool life. Its axial cutting method can effectively reduce radial force and improve stability, making it particularly suitable for deep cavity processing in industries such as aerospace and mold making.

(2) Machining of difficult-to-cut materials: Materials such as titanium alloys, high-temperature alloys, and hardened steel have high hardness and poor thermal conductivity, and traditional milling can easily cause excessive cutting tool wear. Since the cutting force is concentrated in the axial direction, plunge milling provides better heat dissipation, which can extend cutting tool life and improve machining efficiency.

(3) Heavy-duty rough machining: During the rough machining stage, where large amounts of material need to be removed quickly, layered cutting can be performed efficiently, saving time compared to conventional milling. This is particularly suitable for the initial machining of large castings and forgings.

(4) Thin-walled part machining: Thin-walled parts are prone to deformation due to radial cutting forces in traditional milling. However, the axial feed method of plunge milling reduces the risk of workpiece deformation and improves machining accuracy.

B. Multiple advantages in machining

First, the cutting force is more concentrated, effectively reducing radial vibration and significantly improving machining stability;

Second, due to the use of axial cutting, the cutting tool has a longer service life, which is especially suitable for the machining of high-hardness materials and can reduce cutting tool wear.

In addition, plunge milling is highly efficient and particularly suitable for large-volume removal, which can greatly shorten the machining time. At the same time, it performs well in the machining of complex structures, such as deep cavities and narrow grooves, which are difficult to handle with traditional milling.

However, plunge milling also has certain limitations. On the one hand, its surface quality is usually low, and it is mostly used for rough machining, while finishing still requires the combination of other milling methods. On the other hand, it has high requirements for machine tools and cutting tools, requiring equipment with good rigidity, otherwise it is prone to vibration, which affects the machining effect.

That's all for now. For more related knowledge, please feel free to consult us!

- The same milling cutter, the market phenomenon of milling cutter price difference

- Korean customers visited our company to discuss a new chapter of milling cutter cooperation!

- Using the wrong cutting fluid is like throwing away money on milling cutters?

- Zongyeda Explains - Clockwise or Counterclockwise Rotation for Woodworking Milling Cutters?

- Zhongyeda - What's the Difference Between Chamfering Tools and Centering Drills?

- How to Scientifically Determine the Milling Depth for Woodworking Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.