Email Us

What types of diamond tools are there?

Diamond has the advantages of extremely high hardness and wear resistance, low friction coefficient, high elastic modulus, high thermal conductivity, low thermal expansion coefficient, and low affinity with non-ferrous metals. It is currently a tool material with very high hardness. So what types of diamond tools are there? Let's follow the editor of Zhongyeda to take a look!

Types of diamond tools:

Diamond tools are divided according to tool structure: mainly used for turning tools, milling cutters, reamers, drill bits, coated tools and other non-standard forming tools.

1. Diamond blades

1. Standard blades: Single crystal diamond blades are mainly used for single-point diamond lathes or other precision lathes. The surface roughness can reach Rz0.1-0.05μm when processing non-ferrous metals. Polycrystalline diamond (PCD) blades are generally used in lathes, machining centers, etc., mainly for turning and boring. Compared with traditional alloy blades, higher feed and linear speed can be used; blade life is also greatly improved compared with carbide blades; at the same time, the surface finish of the workpiece processed by PCD blades can reach Ra0.2 at best.

2. Non-standard blades: mainly used for some working conditions with complex structures, strict tolerance requirements and complex processing procedures. The use of machine-clamped polycrystalline diamond (PCD) non-standard blades can greatly improve the processing efficiency. At the same time, the use of machine-clamped structure can reduce production costs.

2. Diamond milling blades

Polycrystalline diamond (PCD) milling blades, with milling cutter discs or milling cutter rods, are generally used for milling planes and steps. The linear speed can be as high as 2500-3000m/min. Compared with carbide blades, the tool life is increased by 5-10 times. It is the choice for non-ferrous metal surface milling such as automotive aluminum alloy cylinder heads, motorcycle boxes, and mold planes! The price-performance ratio is very suitable.

3. Diamond rod milling cutter

Diamond rod milling cutters are divided into single crystal diamond milling cutters and polycrystalline diamond (PCD) milling cutters.

Polycrystalline diamond (PCD) rod milling cutters are divided into two types. One is a through-center milling cutter, which can be used to penetrate the workpiece surface vertically along the axis. For milling pit-like workpieces, the efficiency will be greatly improved. The other is a non-through-center milling cutter. This type of milling cutter generally cuts into the workpiece radially, and mills bosses, steps, surfaces and other parts through CNC programming.

4. Diamond reamer

Diamond reamer, generally based on the diameter size, uses an alloy matrix or a steel matrix, and the number of cutting edges is 2 or more.

This type of tool is mainly used for processing holes with strict tolerance requirements and high finish requirements. Both through holes and blind holes can be processed. The finish of the holes processed by this type of tool can reach up to Ra0.1.

5. Diamond drill bits

Polycrystalline diamond (PCD) drill bits are generally made of alloy or steel substrates according to the diameter. Polycrystalline diamond (PCD) drill bits drill holes directly on the workpiece. There are no holes on the workpiece itself, and the precision requirements are not high. PCD drill bits are only suitable for machining center equipment.

Polycrystalline diamond (PCD) drill bits mainly include: PCD hole expansion drill bits, PCD step drill bits, PCD twist drill bits, PCD flat bottom drill bits, etc.

6. Diamond coated tools

Diamond coated tools use the CVD method to directly deposit a 1-25μm diamond film on a substrate such as cemented carbide or ceramics. They can be used for tools with complex geometric shapes and are ideal tools for processing difficult-to-process materials.

Tool types suitable for coating: blades, milling cutters, drill bits, reamers, forming cutters, etc.

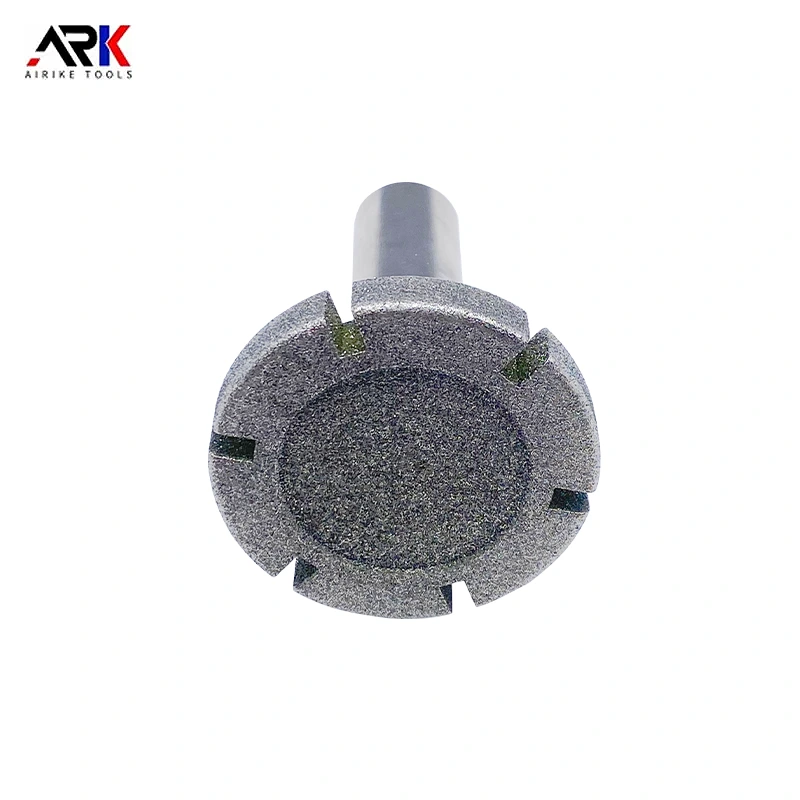

7. Diamond forming tool

Polycrystalline diamond (PCD) forming tool belongs to the rotary tool. Its advantage is high processing efficiency. It can mill multiple step holes at the same time and ensure relatively accurate geometric tolerances. It is divided into two types according to different processing methods. One is axial processing and one-time forming; the other is CNC programming and trajectory processing. The tool holder has BT handle, HSK handle, straight handle, etc.

The above types of diamond tools are shared here. There are many types of diamond tools with significant performance differences. There are also great differences in the structure, preparation method and application field of different types of diamond tools.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.