Email Us

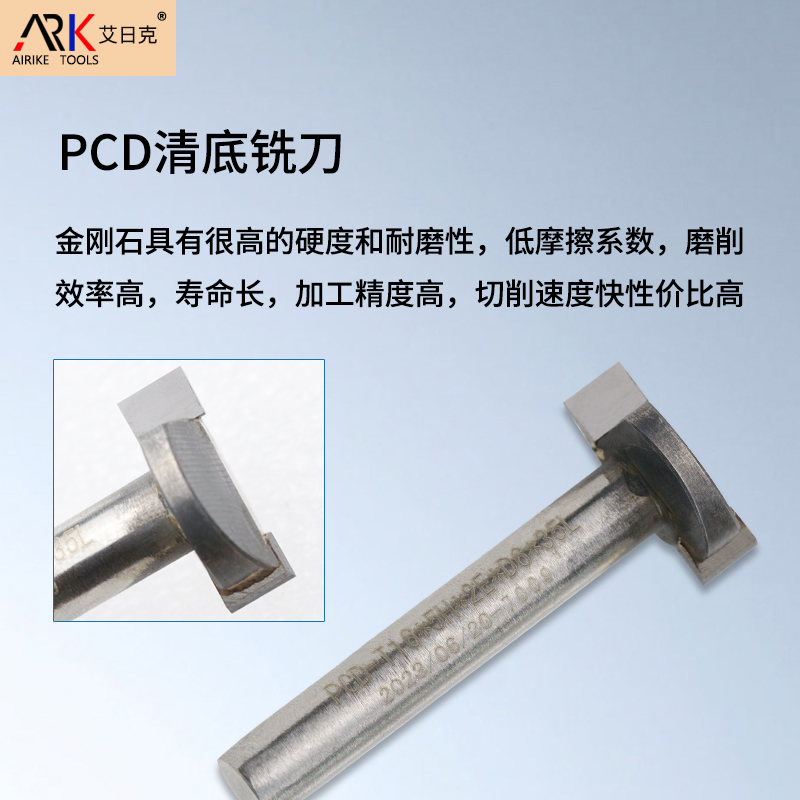

PCD tool grinding requirements for tooling

PCD tools are made by sintering diamond micropowders with metal binders such as cobalt under high temperature and ultra-high pressure conditions. The whole tool is sintered into a milling cutter for milling. However, the high hardness and high wear resistance of PCD tools make it a relatively difficult tool to grind. The ideal method is to use diamond grinding wheels for grinding or grinding. Because the grinding of PCD tools has requirements for tooling, the following editor of Zhongyeda will introduce it to you.

The requirements for tooling for PCD tool grinding are as follows:

1. The machine tool has good process system rigidity.

2. The machine tool has a short-range swing mechanism with adjustable stroke and speed.

3. The tool holder of the machine tool has a high-precision rotation function and an online detection device.

The above requirements for tooling for PCD tool grinding are shared here. Because PCD tools have the advantages of high hardness, high thermal conductivity, low thermal expansion coefficient, high elastic modulus and low friction coefficient, they have been widely used in various industries.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.