Email Us

Metal Cutting Milling Cutter

Zhongyeda's high-quality and durable metal cutting milling cutters are usually made of high-performance materials such as carbide, high-speed steel, ceramics or cubic boron nitride (CBN) to ensure that the cutter has excellent wear resistance and heat resistance during high-load and high-speed cutting. The cutter body design focuses on rigidity and balance to ensure stability and cutting accuracy during the cutting process. At the same time, the cutting edge shape and angle of the milling cutter are precisely calculated and processed to optimize cutting performance, reduce cutting force and cutting heat, and extend the service life of the tool.

Our metal cutting milling cutters are of various types, mainly divided into flat bottom milling cutters, ball head milling cutters, end milling cutters, slot milling cutters and other types according to different cutting methods and uses. Flat bottom milling cutters are mainly used for cutting planes and grooves; ball head milling cutters are suitable for processing three-dimensional curved surfaces and complex shapes; end milling cutters are often used for contour cutting and slot processing; slot milling cutters are specially used for processing various slots and keyways.

Metal cutting milling cutters have significant characteristics such as efficient cutting, high-precision processing, high wear resistance and high stability. Its efficient cutting performance can greatly improve production efficiency and shorten processing cycle; its high-precision processing capability can ensure that the size and shape of the processed parts meet the design requirements and improve product quality; its high wear resistance and high stability can extend the service life of the tool, reduce the frequency of tool replacement, and reduce production costs.

- View as

Integral Alloy T-Type Cutter

Taper Milling Cutter

Welded T-Type Cutter

Stainless Steel High-Gloss Chamfering Cutter

Aluminum Milling Cutter

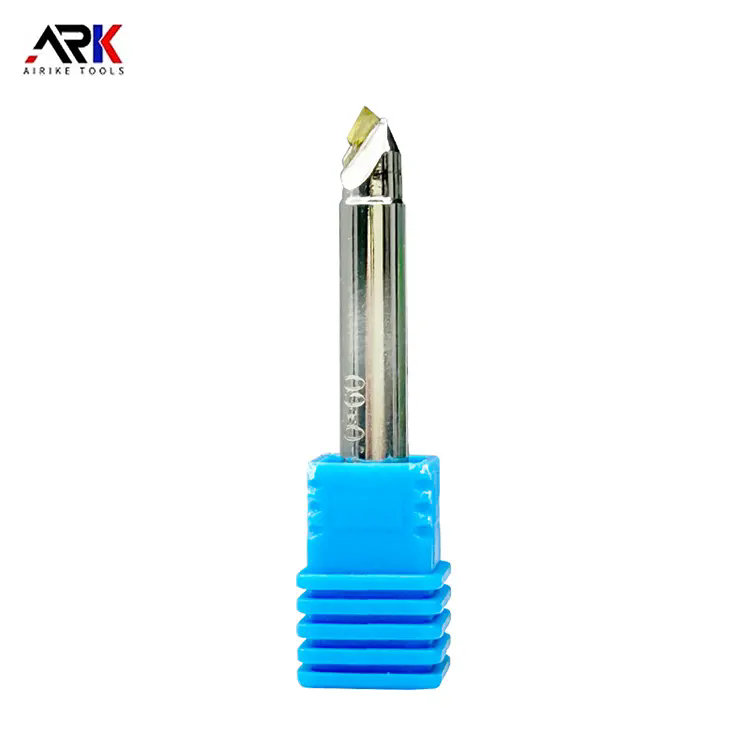

Chamfering Cutter

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.