Email Us

How often is the Engraving Machine Milling Cutter replaced?

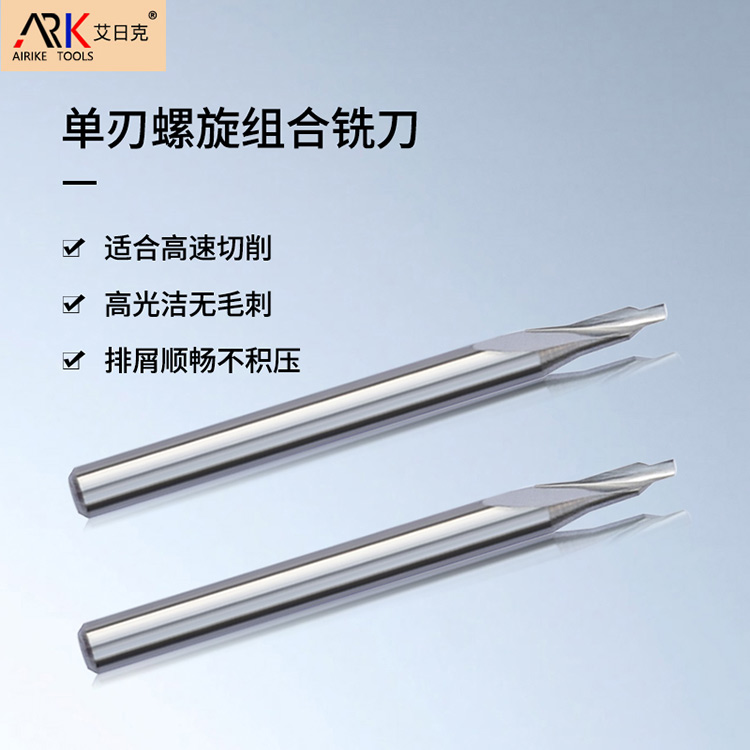

The Engraving Machine Milling Cutter is a tool specifically designed for carving various materials, it has the ability to rotate at high speeds and can quickly cut and carve various shapes and patterns, do you know how often engraving machine milling cutters are usually replaced? Below, the editor of Zhongyeda will introduce it to everyone.

The replacement frequency of the Engraving Machine Milling Cutter is not fixed and is influenced by various factors, including but not limited to the following:

Usage frequency: If the engraving machine is used frequently, the wear rate of the milling cutter will also increase accordingly, so it needs to be replaced more frequently. On the contrary, if the frequency of use is low, the wear rate of the milling cutter will slow down, and the replacement cycle can be relatively extended.

Processing materials: The hardness and properties of the processing materials have a significant impact on the wear of milling cutters. For example, when processing materials with higher hardness, milling cutters wear faster. Therefore, the replacement cycle of milling cutters will also vary depending on the different processing materials.

Cutting conditions: Cutting speed, feed rate, cutting depth, and other cutting conditions can also affect the wear rate of milling cutters. Unreasonable cutting conditions can accelerate the wear of milling cutters, thereby shortening their service life.

Milling cutter quality: The quality of milling cutters is also an important factor affecting their service life. High quality milling cutters typically have better wear resistance and durability, thus extending the replacement cycle.

In practical situations, in order to determine the replacement cycle of engraving machine milling cutters, the following measures can be taken:

Regular inspection: Regularly inspect the milling cutter and observe its wear condition, when obvious wear or damage is found on the milling cutter, it should be replaced in a timely manner.

Record usage data: Record the time, processing materials, cutting conditions, and other information of each use of the engraving machine in order to analyze the wear pattern of the milling cutter.

Reference manufacturer's suggestion: Based on the brand and model of the Engage Machine Milling Cutter, refer to the replacement cycle recommendations provided by the manufacturer.

The above is the relevant content on how often to replace the Engaging Machine Milling Cutter. In general, the replacement cycle of the Engaging Machine Milling Cutter needs to be determined according to the actual situation. By regularly inspecting, recording usage data, and referring to manufacturer recommendations, we can better understand the wear of milling cutters and arrange replacement cycles accordingly.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.