Email Us

How to correctly choose and use a high-gloss knife?

High-gloss cutting tools are not traditional cutting tools. They are usually composed of a precisely machined hard alloy roller (or multiple balls). During operation, they rotate at high speed. By applying appropriate pressure, they flatten and compact the metal surface, eliminating microscopic unevenness and thus forming an extremely smooth surface. This process does not cut off a large amount of material. Instead, it creates a tight and uniform grain structure on the surface through physical deformation, thus achieving a mirror-like effect far exceeding that of ordinary finishing. So, how to correctly choose and use a high-gloss knife? Next, the editor of Zhongyeda will provide a detailed introduction to this issue for everyone.

How to choose the right high-gloss knife?

When choosing a high-gloss cutting, the first step is to clearly define the object to be processed. The cutting properties of different metal materials vary greatly. Copper, aluminum and their alloys are relatively easy to achieve high-gloss effects, while stainless steel, die steel and the like pose greater challenges. Therefore, it is crucial to choose a high-gloss knife that is optimized for specific materials. Typically, such cutting tools adopt special tip geometries, such as having a small negative rake Angle or special edge treatment, to reduce built-up edge during cutting and form an extremely thin cutting layer.

Secondly, consider the material and coating of the cutting tool. Hard alloy with high hardness and high wear resistance is a commonly used base material for high-gloss cutting tools. Advanced PVD coatings, such as TiAlN and AlTiN, not only enhance the durability of cutting tools but also improve surface quality to a certain extent. When making a selection, one should refer to the products recommended by the tool manufacturer for specific materials and processing conditions.

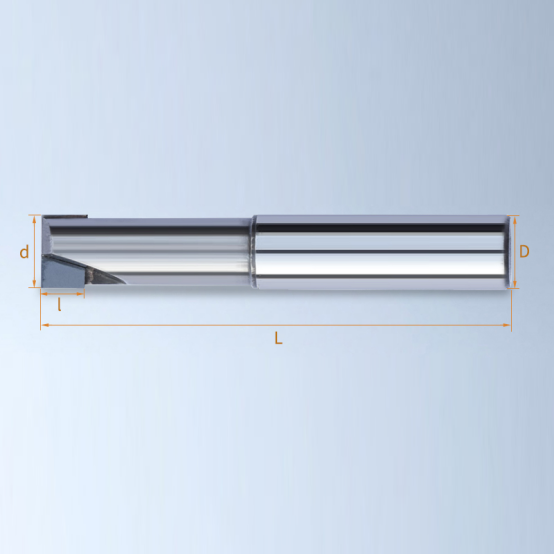

Finally, pay attention to the size and parameters of the cutting tool. The high-gloss effect is extremely sensitive to cutting parameters. Therefore, choosing a high-gloss tool with precise design and strict tolerance is the foundation. The geometric parameters such as the radius of the tool tip and the Angle of the tool tip all need to match your processing strategy.

How to use a high-gloss knife correctly?

When using a high-gloss knife, the setting of cutting parameters is the core. Usually, extremely high spindle speeds and extremely low feed rates are required. High-speed rotation can form a more stable cutting flow, while low-speed feed can ensure that the cutting layer is thin enough, reducing the fluctuation of cutting force and tool vibration. The cutting depth (depth of cut) must be extremely small, often only a few micrometers, and it may even require multiple passes to gradually reach the target depth.

It is crucial to keep the cutting tools and workpieces clean. Any tiny impurity or oil stain may damage the mirror effect. The selection of cutting fluid is also very particular. Generally, it is necessary to use cutting fluid with excellent lubricating performance and less likely to produce oil mist, and ensure an adequate supply and stable pressure.

The rigidity of the machine tool is another key factor. High-gloss processing is extremely sensitive to the vibration of the machine tool. Any slight vibration may cause ripples to appear on the surface. Therefore, before processing, it is essential to ensure that the machine tool is in the best condition, the workpiece is firmly clamped, and the tool is precisely installed without eccentricity.

In conclusion, when choosing a high-gloss cutting, it is necessary to take into account the material properties, and when using it, parameters should be finely adjusted and environmental conditions strictly controlled. Only by fully understanding and adhering to these principles can the high-gloss knife truly exert its charm in creating a mirror-like effect, adding unparalleled luster and value to your workpieces.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.