News

We are pleased to share with you the outcomes of our work, company news, and keep you updated on timely developments as well as the latest personnel appointments and departures.

22 2025-08

22 2025-08 What is the difference between PCD cutting tools and single-crystal cutting tools?

In the field of precision machining, PCD cutting tools and single-crystal diamond cutting tools are two highly regarded ultra-hard material cutting tools. With their exceptional hardness and wear resistance, they make it possible to process a variety of difficult-to-machine materials.

15 2025-08

15 2025-08 What is plunge milling? What are its applications in machining?

In the field of mechanical machining, milling is a common metal cutting method, and plunge milling, as a special milling process, is increasingly gaining attention in high-efficiency machining. So, what exactly is plunge milling? What are its unique applications and advantages in machining?

14 2025-08

14 2025-08 What materials are welded milling cutters suitable for machining?

In the vast field of industrial processing, welded milling cutters cleverly weld high-performance carbide blades to the cutter body to create an integrated structure that combines rigidity and cutting efficiency, making it easy to handle both simple processing and complex tasks. So, what materials are welded milling cutters suitable for processing?

08 2025-08

08 2025-08 Which material is more durable for engraving machine milling cutters?

The durability of milling cutters is directly related to processing efficiency and cost. Faced with a wide variety of materials on the market, how to choose a cutting tool that is both durable and suitable for specific processing scenarios is a concern for many operators. So, which material is more durable for engraving machine milling cutters?

08 2025-08

08 2025-08 How to correctly choose and use a high-gloss knife?

High-gloss cutting tools are not traditional cutting tools. They are usually composed of a precisely machined hard alloy roller (or multiple balls).

07 2025-08

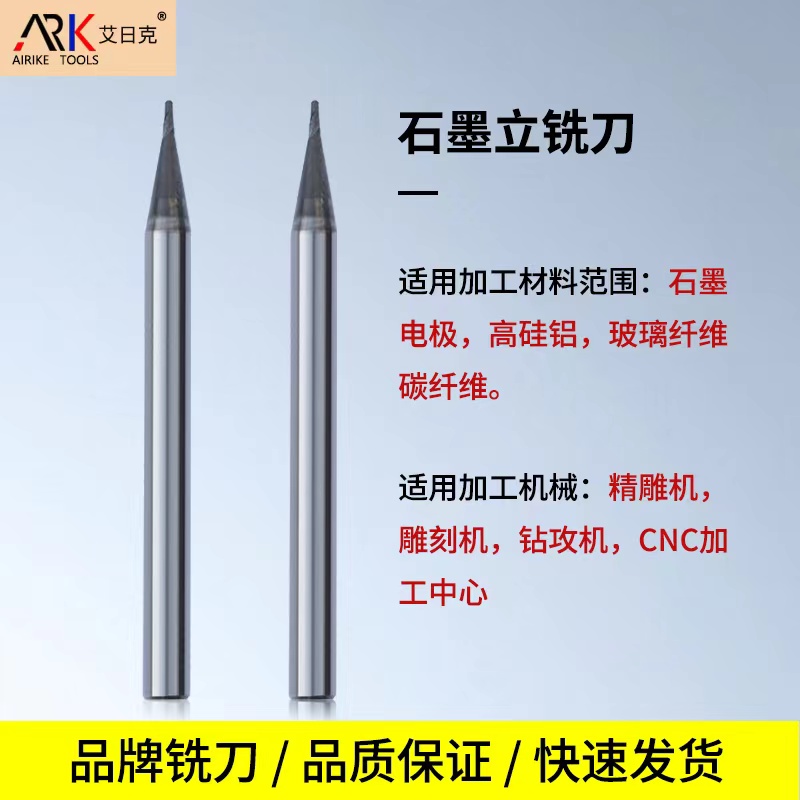

07 2025-08 Which is more commonly used, graphite milling cutters or tungsten carbide milling cutters?

In the field of advanced manufacturing, milling cutters are indispensable tools. When it comes to machining hard and wear-resistant materials, graphite milling cutters and tungsten carbide milling cutters often become the focus of attention. So, which one is more commonly used?