Email Us

Which is more commonly used, graphite milling cutters or tungsten carbide milling cutters?

In the field of advanced manufacturing, milling cutters are indispensable tools. When it comes to machining hard and wear-resistant materials, graphite milling cutters and tungsten carbide milling cutters often become the focus of attention. So, which one is more commonly used? Below, Zhongye Da will give you a detailed introduction.

Tungsten carbide milling cutter:

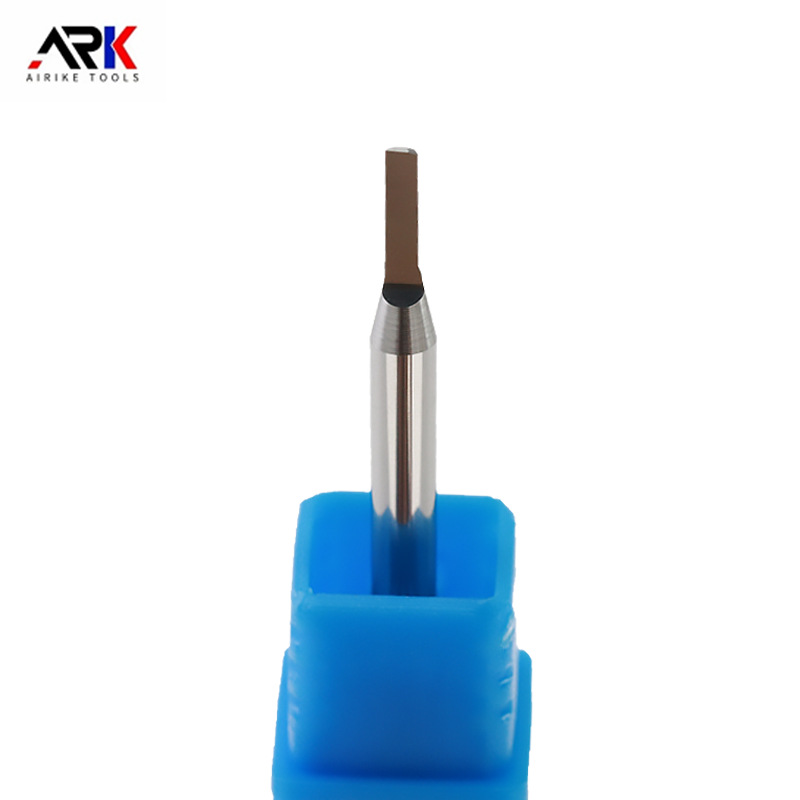

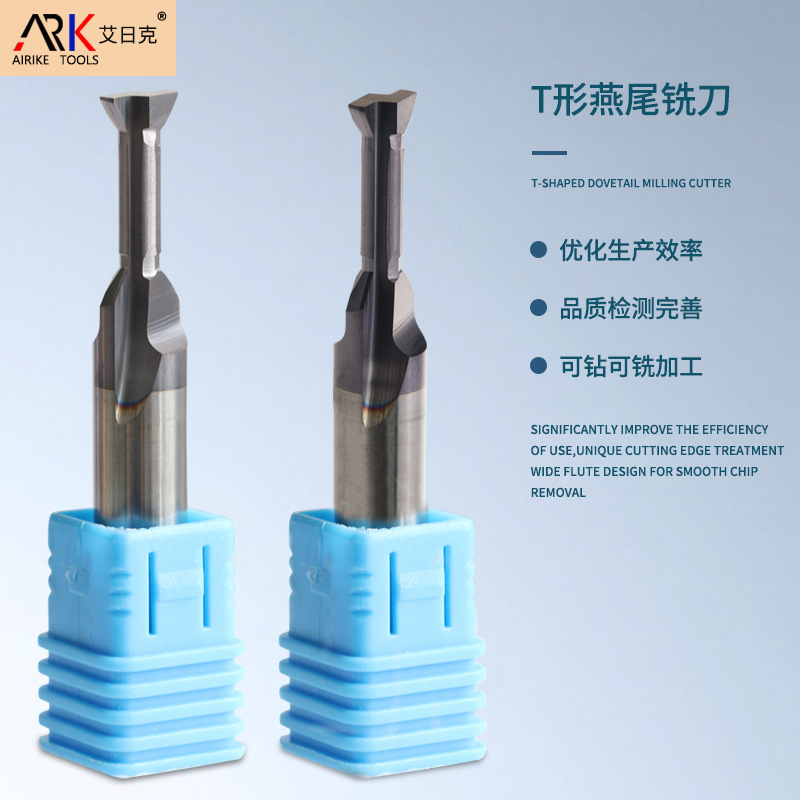

This usually refers to a milling cutter made of tungsten carbide as the hard alloy base material. Tungsten carbide itself is a compound composed of carbon and tungsten, which has extremely high hardness, wear resistance, and high temperature resistance. This makes tungsten carbide milling cutters ideal for processing a variety of materials such as steel, cast iron, non-ferrous metals, and composite materials.

Its wide application is reflected in almost all metal processing fields: from precision milling of auto parts to the manufacture of complex structural parts in the aerospace field; from mold engraving to the processing of metal shells for electronic products, tungsten carbide milling cutters are everywhere. It is highly versatile and can adapt to a variety of cutting speeds and feed rates, with a wide processing range. It can be said that in the vast field of metal processing, tungsten carbide milling cutters are the absolute mainstay, far surpassing many other types of milling cutters in terms of frequency of use and popularity.

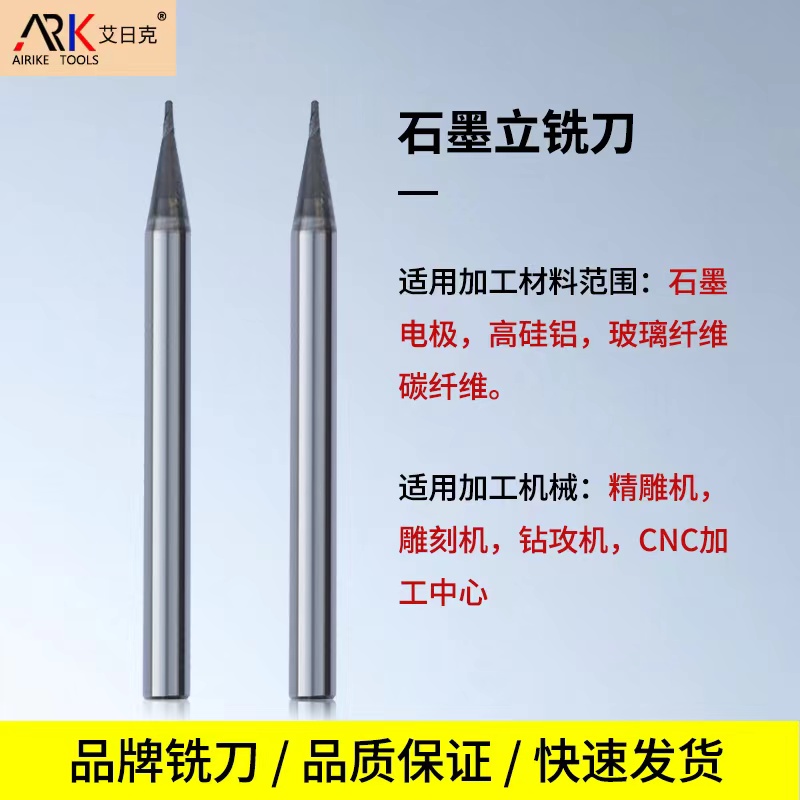

Graphite milling cutters:

This is a more specialized tool, mainly used for processing graphite materials. Due to its unique physical and chemical properties, such as high heat resistance, high electrical and thermal conductivity, self-lubrication, and chemical stability, graphite is widely used in semiconductor manufacturing (such as wafer processing), EDM (electrical discharge machining) electrode manufacturing, lithium-ion battery negative electrode materials, fuel cells, high-temperature furnace components, and other fields.

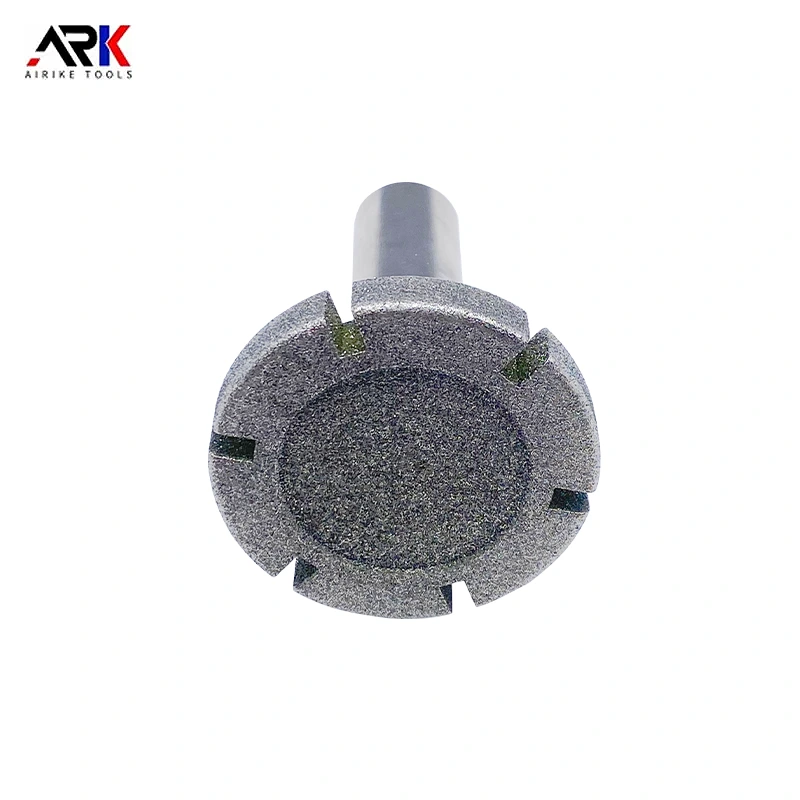

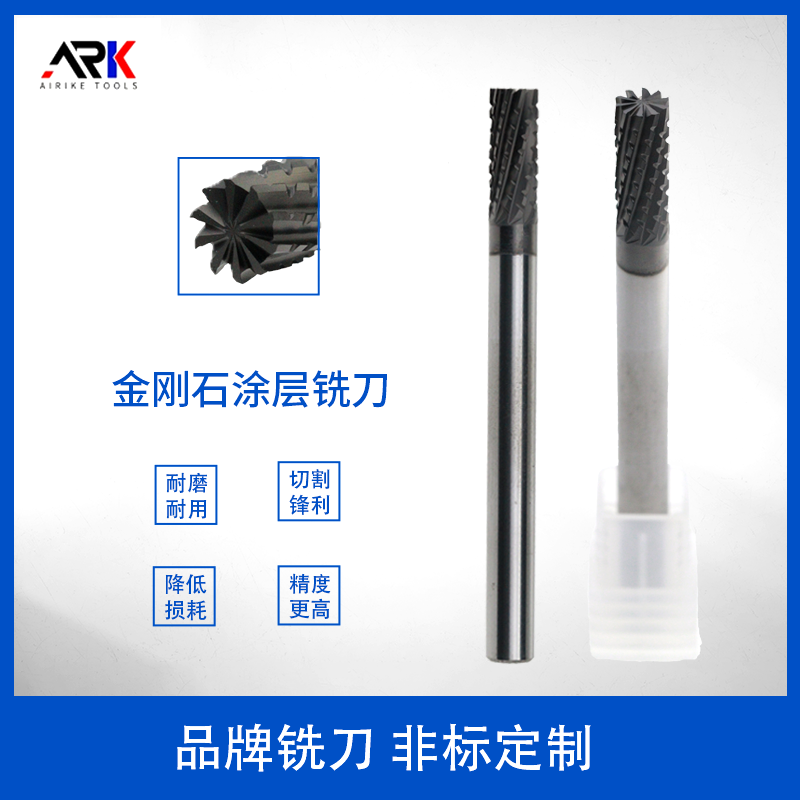

The design and manufacture of graphite cutters has its own special characteristics. Due to the relative brittleness of graphite materials, dust is easily generated during processing, which places special requirements on the cutting edge and chip removal capacity of the cutting tool. Therefore, it usually adopts special geometric shapes, such as a larger helix angle or a unique cutting edge design, to reduce cutting force, prevent graphite fragmentation, and effectively remove graphite dust to avoid secondary wear. In addition, in order to protect the environment and the health of operators, dust collection devices are usually required when processing graphite, which also places higher demands on the chip removal performance of milling cutters.

Comparison of common use:

Wide range of applications: Tungsten carbide milling cutters can process most common engineering materials, covering most areas of the manufacturing industry. The application of graphite cutters is highly concentrated in specific graphite processing fields.

Large market size: Since the volume of metal processing is much greater than that of graphite processing, the market demand for tungsten carbide milling cutters is huge, and they are used in almost every mechanical processing workshop. Graphite milling cutters mainly serve relatively specialized industries such as semiconductors, EDM, and new energy.

High versatility: The versatility of tungsten carbide milling cutters makes them a “panacea” for many processing tasks, while graphite cutters are highly specialized tools that are only used for graphite processing tasks.

In summary, tungsten carbide milling cutters have become the more commonly used tool in the field of industrial milling due to their wide applicability and huge market demand. Graphite milling cutters, on the other hand, play an irreplaceable role in specialized fields due to their special design and performance for graphite materials. Both have their own advantages and serve the different needs of modern manufacturing.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.