Email Us

Which material is more durable for engraving machine milling cutters?

The durability of milling cutters is directly related to processing efficiency and cost. Faced with a wide variety of materials on the market, how to choose a cutting tool that is both durable and suitable for specific processing scenarios is a concern for many operators. So, which material is more durable for engraving machine milling cutters? Let's take a look with Zhongye Da!

High-speed steel milling cutters: economical but with limited durability

High-speed steel is one of the most traditional materials for engraving machine milling cutters. It has good toughness and vibration resistance, performs stably when processing soft materials such as ordinary wood and foam, and is relatively inexpensive, making it suitable for users with limited budgets. However, high-speed steel has relatively low hardness and wear resistance. When processing harder materials or cutting at high speeds, the cutting edge is prone to wear and tear, resulting in poor durability.

For precision machining or high-intensity operations with high requirements, high-speed steel milling cutters are often not up to the task and need to be replaced or sharpened frequently, which increases the cost of use in the long run.

Carbide milling cutters: the mainstream choice for high durability

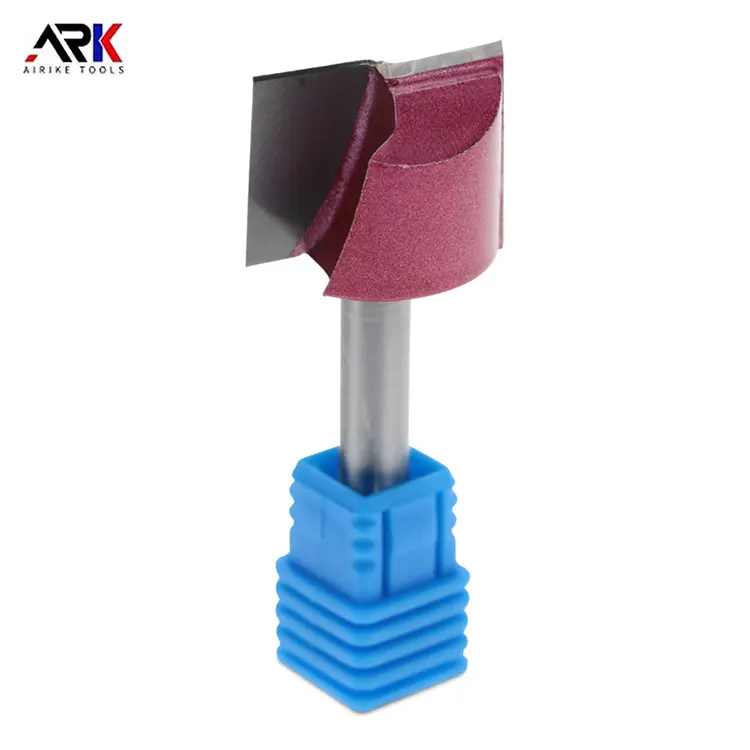

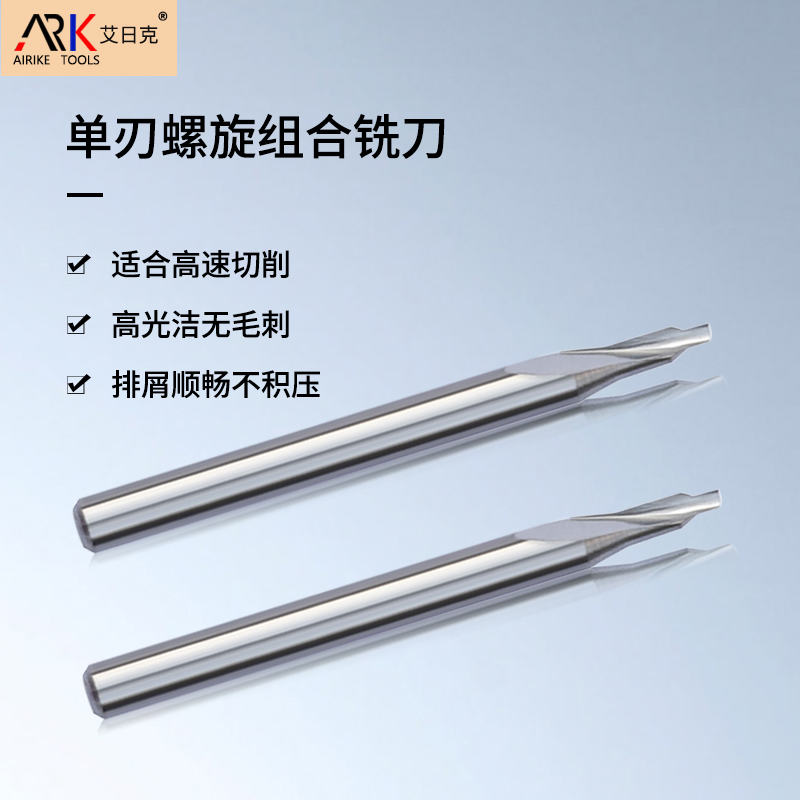

Carbide milling cutters are currently one of the most widely used milling cutter materials. They are made of hard phases such as tungsten carbide and titanium carbide, as well as binders such as cobalt, and have extremely high hardness and wear resistance. Under high-speed cutting conditions, carbide milling cutters can maintain good cutting performance, with cutting speeds several times higher than high-speed steel, greatly improving processing efficiency. At the same time, they have excellent wear resistance and a service life far exceeding that of high-speed steel milling cutters. Carbide milling cutters are suitable for processing a variety of materials such as wood, plastic, and aluminum alloy, and are the mainstream choice for engraving machine users.

Although the initial cost of carbide milling cutters is relatively high, their durability means that they need to be replaced less frequently, making them more economical in terms of overall cost. In addition, modern carbide milling cutters often use coating technology to further enhance their hardness and wear resistance, allowing them to remain sharp even under more severe processing conditions.

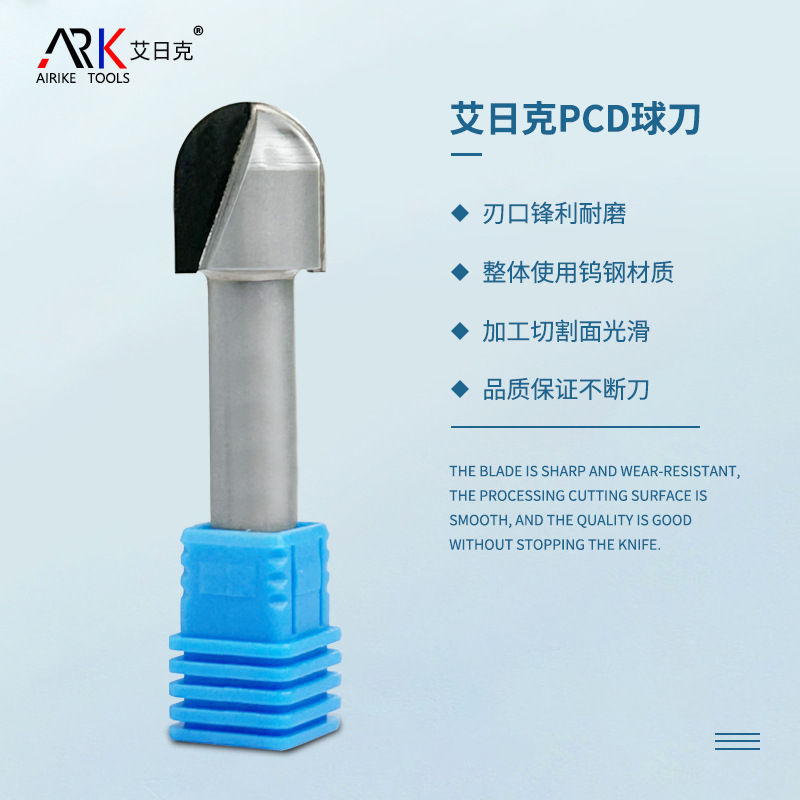

PCD milling cutters: extreme durability, but high price

PCD (polycrystalline diamond) milling cutters are made of synthetic diamond and have extremely high hardness and wear resistance, making them one of the most durable of all milling cutter materials. PCD milling cutters are particularly suitable for machining high-hardness, high-wear-resistant materials such as aluminum alloys, magnesium alloys, and composite materials. They can maintain a sharp cutting edge for a long time, significantly reducing wear. However, PCD milling cutters are extremely expensive to manufacture, costing several times or even dozens of times more than ordinary carbide milling cutters.

In addition, PCD material is not suitable for ferromagnetic materials such as steel, and has poor impact resistance, making it prone to chipping when subjected to large impacts. Therefore, PCD milling cutters are usually only used in specific situations where machining accuracy and cutting tool life are extremely important, such as in high-end manufacturing fields such as aerospace and automotive molds.

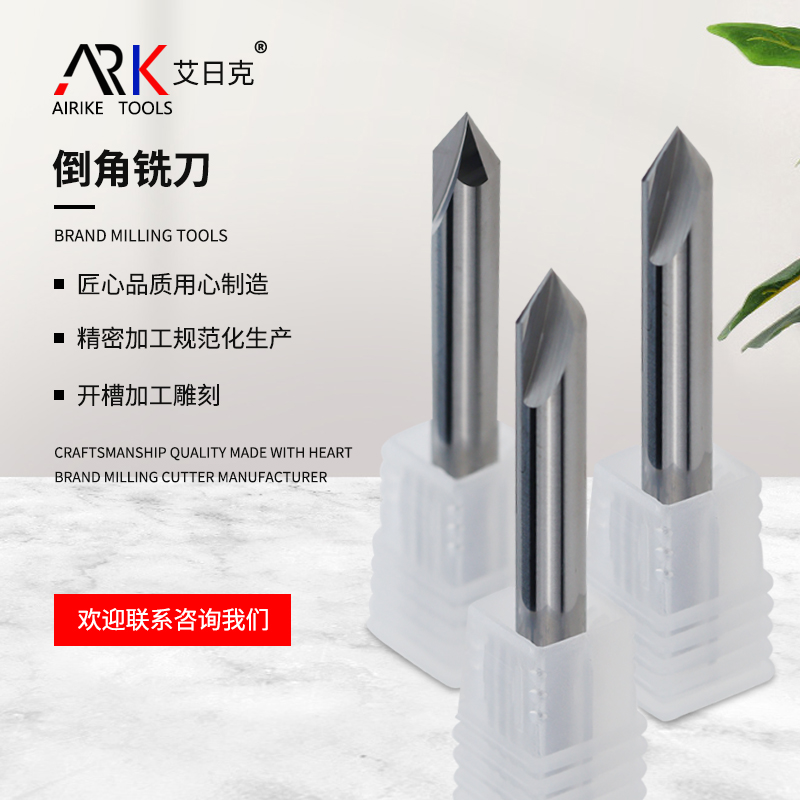

Other special materials: ceramics and CBN

Ceramic milling cutters have extremely high hardness and wear resistance, and are suitable for machining high-hardness, high-strength, difficult-to-machine materials such as hardened steel and high-temperature alloys. However, ceramic materials are brittle and have poor impact resistance, requiring high machine tool rigidity and operating skills. Once the cutting parameters are improper or an impact occurs, the cutting edge is extremely prone to chipping. Therefore, the scope of application of ceramic milling cutters is limited, and they are mainly used in specific high-end machining fields.

Cubic boron nitride (CBN) milling cutters are similar to ceramics in that they have extremely high hardness and thermal stability, making them particularly suitable for machining difficult-to-machine materials such as hardened steel and cold-hardened cast iron. CBN milling cutters have excellent high-temperature resistance and remain sharp under high-temperature cutting conditions, but they are also expensive and are not suitable for machining non-ferrous materials.

In summary, the durability of engraving machine milling cutters is closely related to their material properties. When selecting a milling cutter, factors such as the hardness of the material being processed, cutting conditions, cost budget, and machine tool performance should be taken into consideration in order to find a durable milling cutter material and achieve efficient and stable processing.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.