Email Us

Why is there such a big price difference for the same milling cutter?

As a core cutting tool in the machinery manufacturing industry, milling cutter plays an indispensable role in a number of industries, and its application range is extremely wide, being used in many fields such as aerospace, rail transportation, intelligent equipment marine engineering, etc., from large to high-precision manufacturing plants, small to individual machining enterprises can be applied to the milling cutter.

Wide choice of milling cutter on the market, the price range span, cheap milling cutter may only need a few dollars, while the expensive high-end milling cutter can be sold to hundreds or even thousands of dollars. Many companies in the procurement of milling cutter do not know which price of the milling cutter is appropriate, too high beyond the budget, too low to worry about the quality. Then the price of cheap and expensive milling cutter in the end what difference exists?

First, the difference between the raw material of milling cutter

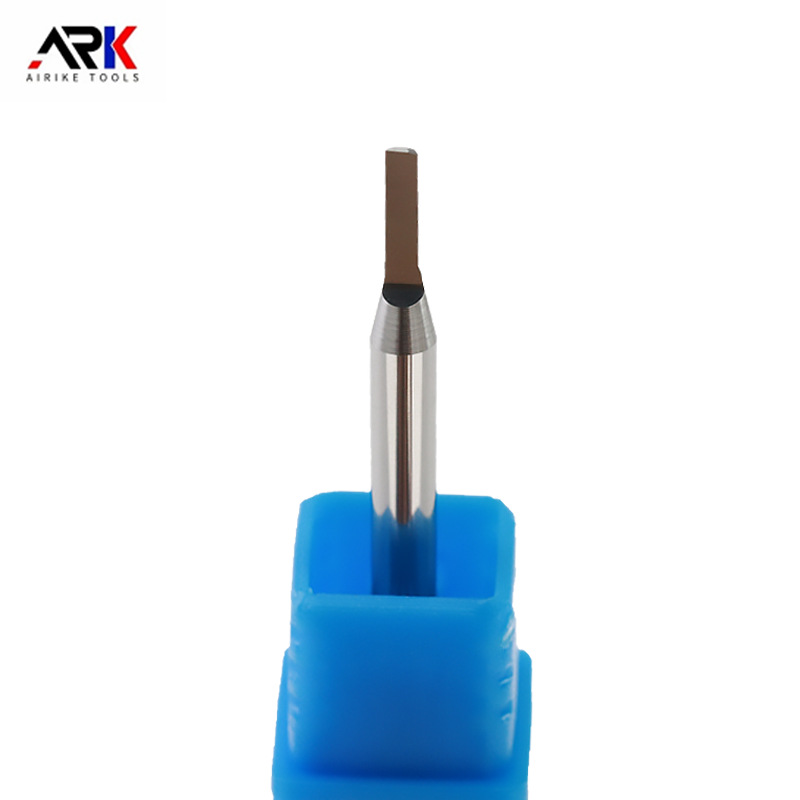

The raw material of milling cutter can be divided into tungsten steel, high-speed steel, ceramic, diamond and so on. The cost of high-speed steel milling cutter is lower than tungsten steel but not durable, ceramic milling cutter, diamond milling cutter processing effect is good but the price is too expensive, and tungsten steel is moderately priced and durable, is the most common milling cutter material.

In addition, tungsten steel material is also divided into raw material and recycled material, the so-called raw material is directly processed from raw materials; recycled material is some wear and tear milling cutter can not be recycled after the second processing, raw material will be higher than the cost of recycled material, so made of raw materials milling cutter price will be more expensive than the recycled material milling cutter.

Second, the difference in processing equipment

Processing and production of milling cutter machinery and equipment, is undoubtedly one of the key factors affecting the price of data cutting tool. In the market, imported high-precision machinery and equipment is usually known for its excellent performance and stability, these devices are often expensive, the cost is much higher than domestic equipment.

Imported equipment in the design, manufacturing process using more advanced technology, making them able to produce milling cutters with a higher degree of precision, this high-quality equipment will naturally bring a higher price milling cutter. In contrast, the domestic milling cutter, although the function and reliability is also a good performance, but in the fineness and machining efficiency may not be able to match the imported equipment.

Third, the difference between the level of master craftsmanship

The difference between experienced masters and general masters is obvious, they are in the same mechanical equipment manufactured milling cutter product quality has a significant difference. Novice may need to spend more time and effort to ensure that every detail is optimized, which is mainly reflected in the milling cutter on the degree of fineness.

In short, milling cutters don't have to be expensive, but they do have to be the right ones. Excluding the quality itself, each material made out of milling cutter itself is not absolutely good or bad, only in the case of budget and processing material match, is the best choice.

- The same milling cutter, the market phenomenon of milling cutter price difference

- Korean customers visited our company to discuss a new chapter of milling cutter cooperation!

- Using the wrong cutting fluid is like throwing away money on milling cutters?

- Zongyeda Explains - Clockwise or Counterclockwise Rotation for Woodworking Milling Cutters?

- Zhongyeda - What's the Difference Between Chamfering Tools and Centering Drills?

- How to Scientifically Determine the Milling Depth for Woodworking Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.