Email Us

The same milling cutter, the market phenomenon of milling cutter price difference

In the field of mechanical processing, milling cutters are the most basic and most critical cutting tools. Their prices range from ordinary milling cutters of a few yuan to high-end products of thousands of yuan, and the price difference can reach hundreds of times. This huge price difference not only confuses the purchasers who are new to the industry, but even many experienced engineers may not fully understand the reason.

In fact, the difference in the price of milling cutters is by no means accidental, but the result of multiple factors such as material science, manufacturing process, brand value, and application scenarios. There is a wide range of choices for milling cutters on the market, and the price range spans a large range. Cheap milling cutters may only cost a few yuan, while expensive high-end milling cutters can sell for hundreds or even thousands of yuan. Many companies do not know which price of milling cutters to choose when purchasing milling cutters. Too high a price will exceed the budget, and too low a price will worry about the quality. So what is the difference between cheap and expensive milling cutters?

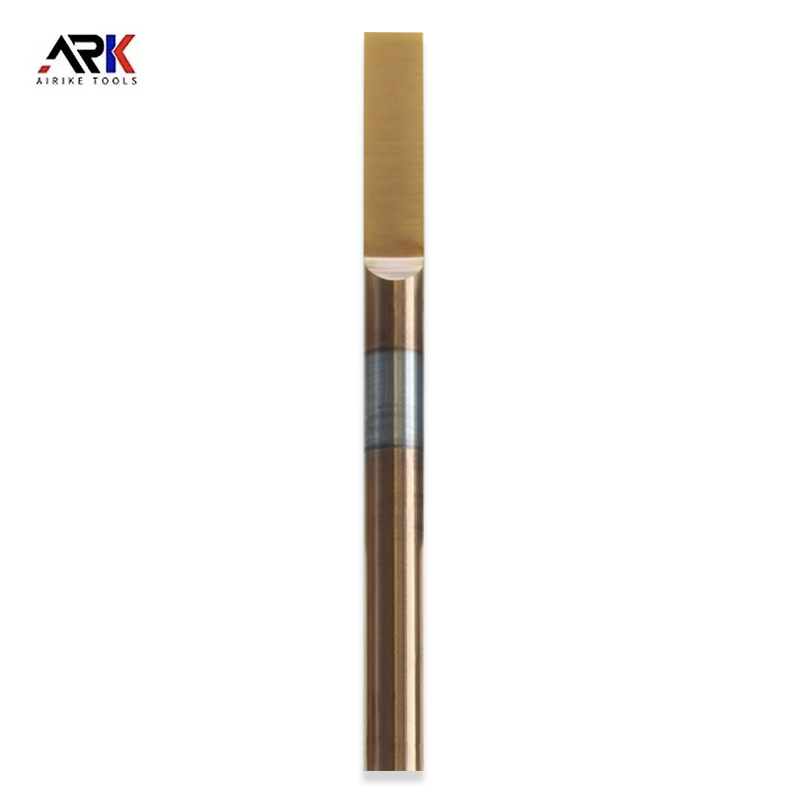

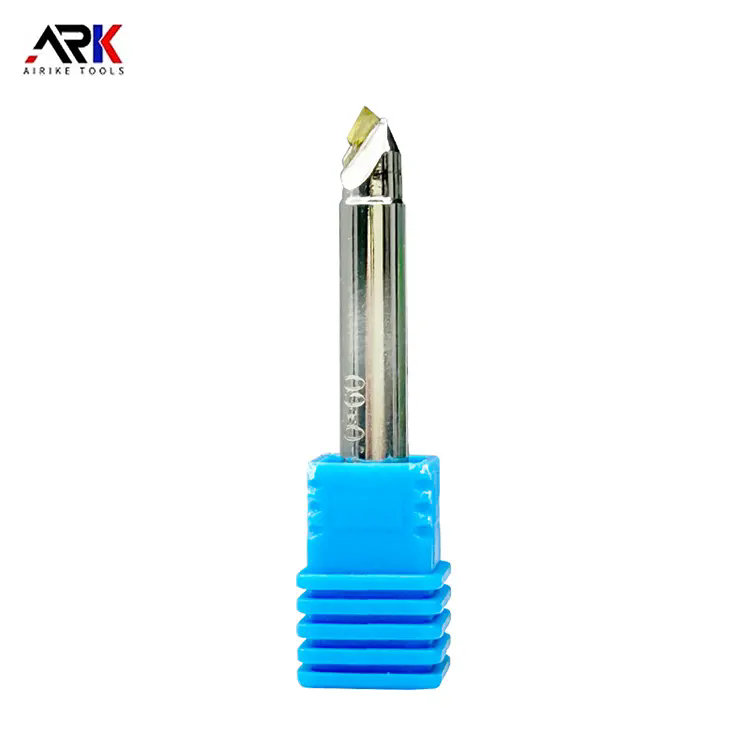

1. Differences in raw materials of milling cutters The raw materials of milling cutters can be divided into tungsten steel, high-speed steel, ceramic, diamond, etc. The cost of high-speed steel milling cutters is lower than that of tungsten steel but they are not durable. Ceramic milling cutters and diamond milling cutters have good processing effects but are too expensive. Tungsten steel is moderately priced and durable, and is the most common material for milling cutters. In addition, tungsten steel materials are also divided into virgin materials and recycled materials. The so-called virgin materials are directly processed from raw materials; recycled materials are recycled after some worn-out milling cutters are processed for the second time. The cost of virgin materials is higher than that of recycled materials, so the price of milling cutters made of raw materials will be more expensive than that of recycled materials.

2. Differences in processing and production equipment The mechanical equipment for processing and producing milling cutters is undoubtedly one of the key factors affecting the price of data tools. In the market, imported high-precision mechanical equipment is usually known for its excellent performance and stability. These equipment are often expensive and cost much more than domestic equipment. Imported equipment uses more advanced technology in the design and manufacturing process, which enables them to produce milling cutters with higher precision. Such high-quality equipment will naturally bring higher-priced milling cutters. In contrast, although domestic milling cutters also have good performance in terms of function and reliability, they may not be comparable to imported equipment in terms of precision and processing efficiency.

3. Differences in the craftsmanship of masters

The difference between experienced masters and ordinary masters is obvious. The quality of the milling cutter products they produce on the same mechanical equipment is significantly different. Novices may need to spend more time and energy to ensure that every detail is in the best state, which is mainly reflected in the fineness of the milling cutter.

After understanding the nature of the price difference of milling cutters, a scientific procurement strategy can be formulated:

1. Material matching principle: Do not excessively pursue high-performance materials. It may be more economical to use high-quality high-speed steel than low-end cemented carbide to process ordinary carbon steel.

2. Principle of precision application: Use ordinary-grade milling cutters for rough processing, and use high-precision products for key processes to achieve the optimal cost configuration.

3. Full life cost calculation: Considering the price of a single piece × the number of uses + the time cost of tool change + scrap loss, high-end tools are often more cost-effective in mass production.

4. Professional selection: Special milling cutters must be used for specific materials (such as high-temperature alloys and composite materials). They seem expensive but actually save comprehensive costs. Enterprises can break the mindset of "the more expensive the better" or "the cheaper the more economical", establish a scientific tool selection system, and ultimately achieve a perfect balance between processing efficiency and cost control. In the era of intelligent manufacturing, accurate judgment of tool value will become an important part of the core competitiveness of the manufacturing industry.

- Korean customers visited our company to discuss a new chapter of milling cutter cooperation!

- Using the wrong cutting fluid is like throwing away money on milling cutters?

- Zongyeda Explains - Clockwise or Counterclockwise Rotation for Woodworking Milling Cutters?

- Zhongyeda - What's the Difference Between Chamfering Tools and Centering Drills?

- How to Scientifically Determine the Milling Depth for Woodworking Milling Cutters?

- Metal cutting process inventory, which method of machining is more applicable?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.