Email Us

Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

In machining scenarios, chipping is a frustrating issue many machinists encounter—especially when new milling cutters break shortly after unpacking, severely impacting efficiency. While many blame tool quality, they overlook critical details in handling and storing new cutters. In reality, seemingly simple practices like immediate use after unpacking and careless storage are key reasons for rapid chipping and shortened tool life.

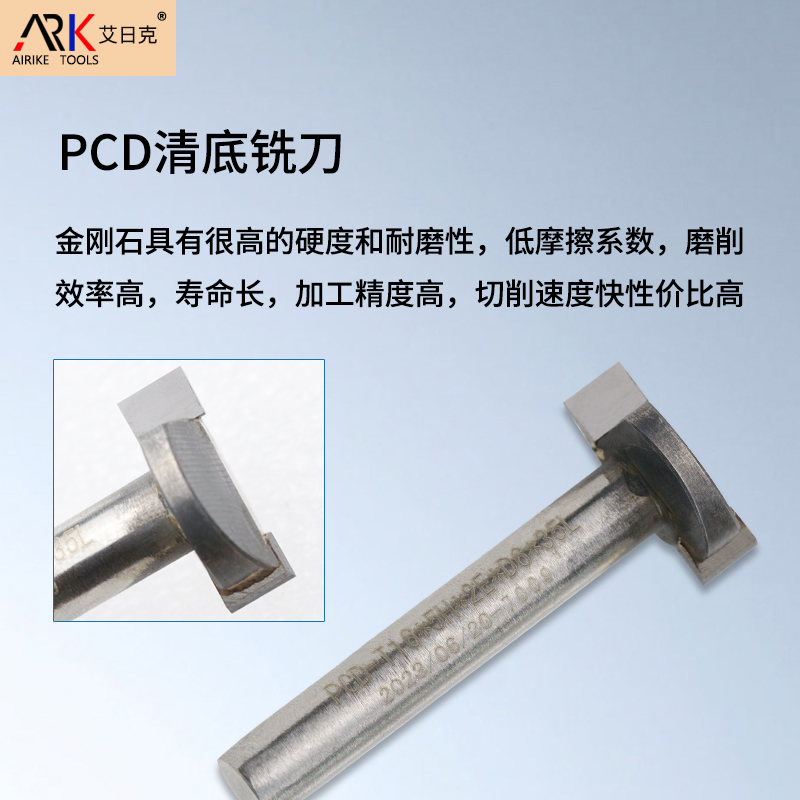

Cutting Tool Chipping Due to Improper Use, Case Study and Anecdote

Master Zhang, who recently purchased Zhongye Da diamond milling cutters, reported that a brand-new tool chipped immediately upon contact with a high-hardness workpiece within half an hour of use. Compounding the issue, careless storage led to the tool becoming unusable within two months. —In our after-sales maintenance, “new tool pre-treatment + standardized storage” form a critical combination. Proper execution can extend tool life by 35%.

After following our recommended edge pre-treatment and storing the tool in a dedicated case, the customer reported: “This tool now handles nearly 50% more work than before, with more uniform surface finish.”

Without further ado, let's get straight to the point!

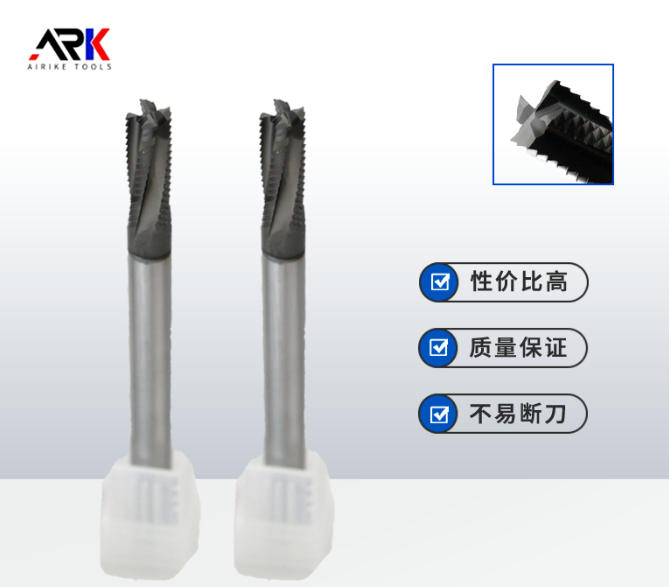

Never use new tools “bare.” Follow these two-step pre-treatment procedures.Both carbide and diamond milling cutters have microscopic burrs on their new cutting edges.

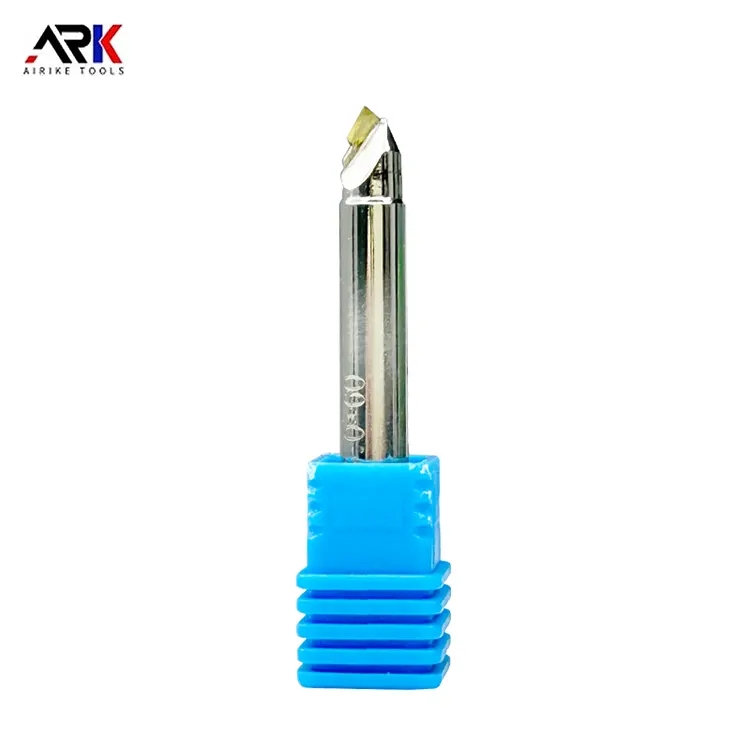

① After unpacking, lightly grind the cutting edge with a fine oilstone. For carbide end mills, create a 0.02mm micro-chamfer (enhances impact resistance). For diamond end mills, remove burrs (prevents edge chipping).

② During workpiece changeovers, use a brush dipped in cutting fluid to clean metal chips from the cutting edge (especially for carbide end mills—chips lodged in gaps can scratch the edge).

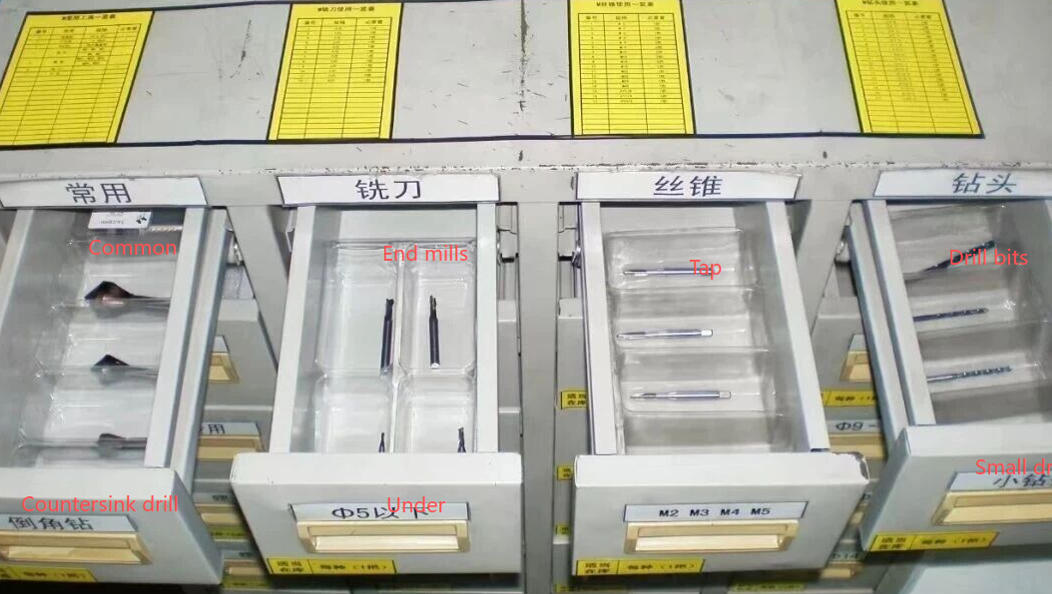

Storage pitfalls: Don't let idle time ruin good tools. Many milling cutters aren't worn out—they're stored out! Remember these 3 storage essentials.

① Store individually in dedicated tool boxes/holders to prevent edge collisions and damage.

② In humid workshops, coat tools with rust-preventive oil or place them in a drying cabinet to prevent edge rusting and dulling.

③ Separate tools for different materials (e.g., steel and aluminum cutters must not be mixed) to avoid cross-contamination from residual chips.

As shown in the diagram, Proper tool storage illustration—actual photos of dedicated racks and dry storage cabinets.

In short, implement these techniques for just one month, and you'll naturally develop the habit. Diamond milling cutter changeover time can drop from 1.5 hours daily to 0.5 hours—reducing costs while boosting production capacity by 25%! Choosing the right tools is fundamental, but proper storage is the key to saving costs!

- What is the welding process for Welded Milling Cutters?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

- How to Choose Between PCD and MCD Tools?

- Your Essential Guide to Choosing the Perfect Engraving Machine Milling Cutter

- Which is better, graphite milling cutter or HSS milling cutter?

- Do you know what are the practical ways to reduce the cost of acrylic milling cutter processing?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.