Email Us

How durable are insulating material milling cutter?

In modern manufacturing, insulating materials are increasingly used, such as epoxy resins, polyimides, polyether ether ketones, and phenolic resin laminates. These materials have become the first choice for critical components due to their excellent insulating properties, high temperature resistance and mechanical strength. However, their characteristics such as high hardness, high fiber content and low thermal conductivity also pose a serious challenge to cutting tools for machining. Therefore, the durability of insulating material milling cutter is directly related to the machining efficiency, cost control and final product quality, and has become the core index to measure its performance. How about the durability of insulating material milling cutter? The following follow the Zhongye Da editorial to find out!

First, the key factors affecting the durability

Insulation material milling cutter durability is not a single indicator, but by the material, design, coating and machining process together to determine the complex system.

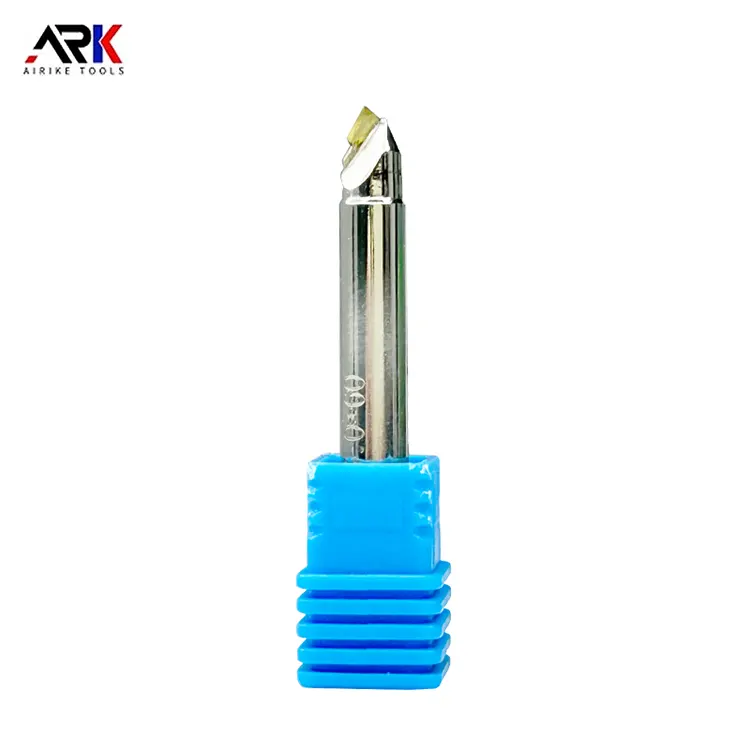

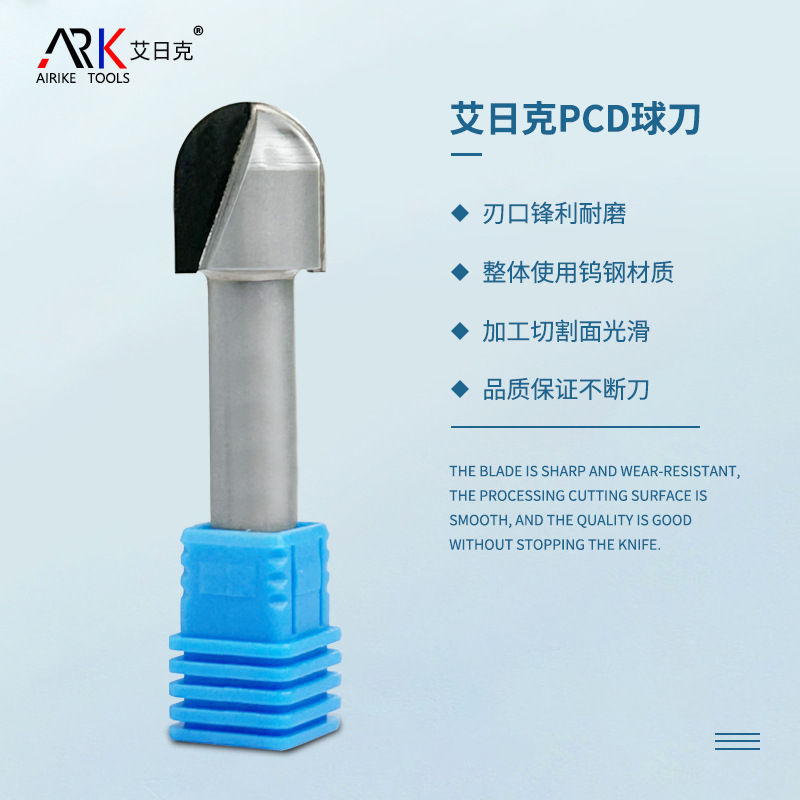

First of all, the cutting tool base material is the cornerstone of durability. High-speed steel cutting tools are low-cost, but have limited hardness and wear resistance, and wear extremely quickly and with poor durability when machining hard insulating materials. Cemented carbide (especially ultra-fine grain carbide) has become the mainstream choice for machining insulating materials due to its extremely high hardness, wear resistance and red-hardness, which can significantly improve cutting tool life. In addition, polycrystalline diamond and cubic boron nitride, as superhard materials, show unparalleled durability when machining extremely hard or highly abrasive insulating materials, but are also relatively costly.

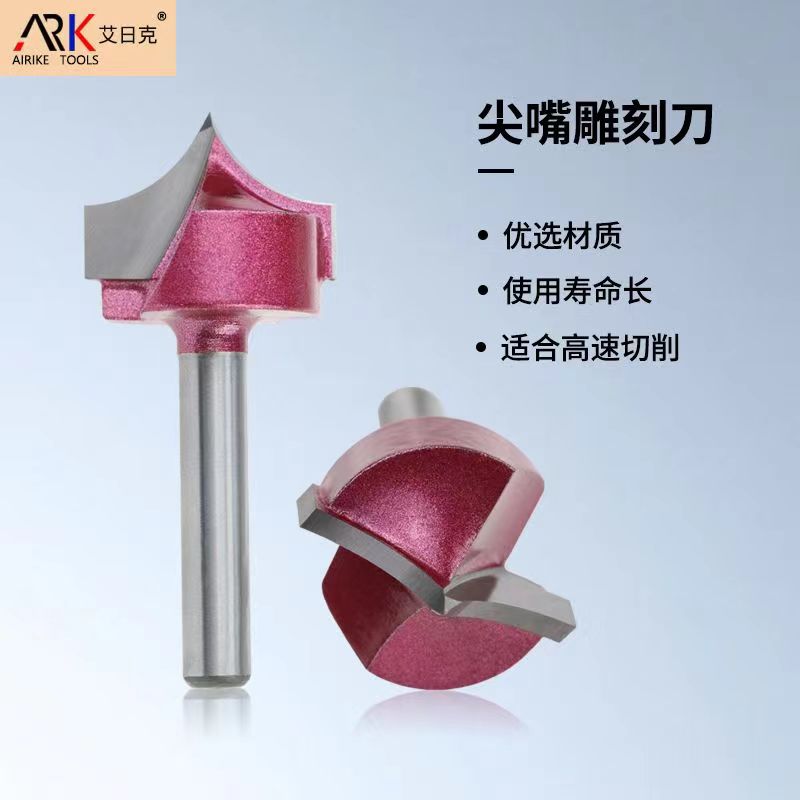

Secondly, the geometric design of the cutting tool and the coating play a decisive role in durability. The high cutting temperatures that are not easily dissipated in the machining of insulating materials can easily lead to softening and burnishing of the cutting tool edge. Therefore, optimized cutting tool design is crucial. For example, the use of sharp and smooth edge can reduce the cutting force and cutting heat; the choice of the appropriate helix angle and chip removal groove to help smooth chip discharge, to avoid the wear of the edge of the second cutting; and increase the chip space can effectively prevent chip clogging.

Coating technology is also a powerful tool to enhance durability. Physical vapor deposition technology prepared by titanium nitride (TiN), titanium aluminum nitride (TiAlN), diamond-like (DLC) and other coatings, these coatings are not only very high hardness, outstanding wear resistance, but also effectively reduce the friction coefficient between the cutting tool and the workpiece, reducing the generation of cutting heat. In particular, TiAlN coating, because of its excellent high temperature oxidation resistance and red hardness, in high-speed dry cutting or processing of high thermal conductivity of poor insulation materials, can greatly extend the life of cutting tools to prevent edge chipping and crescent pits wear.

Second, the actual performance of durability

In practice, the durability of milling cutters for insulating materials varies greatly. Processing of pure resin matrix, cutting tool wear pattern is mainly for the rear face wear and slight dulling of the edge; and once the fiber reinforced materials (such as glass fibers in G10), the situation becomes complex. The hard fibers, like countless tiny abrasives, produce strong abrasive wear on the cutting tool, which can easily lead to chipping and flaking of the cutting edge, which is the most important factor affecting the durability of the tool.

In addition, the choice of processing parameters also directly affect the durability. Too high cutting speed or feed will sharply increase the cutting force and temperature, accelerating tool wear; conversely, too low a parameter will reduce the efficiency, and may be due to insufficient cutting burrs, also affecting the life of the cutting tool. Therefore, to find the balance between machining efficiency and cutting tool durability is the core task of process optimization.

In conclusion, the durability of milling cutters for insulating materials is a comprehensive performance embodiment, which relies on advanced base materials, scientific cutting tool structure design and efficient surface coating technology. In the face of a wide variety of insulating materials with different properties, choosing the right cutting tool and optimizing the machining parameters is the key to achieving efficient, high-quality and low-cost machining.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.