Email Us

What are the factors to consider when choosing a carbon fiber milling cutter?

Carbon fiber milling cutters are tools specifically designed for machining carbon fiber composites and other high-strength, high-hardness materials. Because carbon fiber materials are extremely strong and hard, the machining process can easily lead to cutting tool wear and material delamination, so choosing the right carbon fiber milling cutter is crucial. So what factors need to be considered when choosing a carbon fiber milling cutter? Next, Zhongye da editorial for this issue to introduce in detail.

Selection of carbon fiber milling cutter need to consider the following factors:

First, the material characteristics of the impact of cutting tool selection

Carbon fiber is a high-strength fiber containing more than 90% carbon, its strength is 7 to 10 times higher than steel, widely used in aerospace, automotive manufacturing and other fields. However, the high hardness and brittleness of this material makes the cutting tool easy to wear during processing, and it is very easy to cause material delamination when drilling and milling.2 Therefore, when selecting carbon fiber milling cutters, it is necessary to give full consideration to the hardness of the material and the processing characteristics, and to select a tool with strong abrasion resistance and excellent cutting performance, in order to prolong the life of the tool and to ensure the quality of processing.

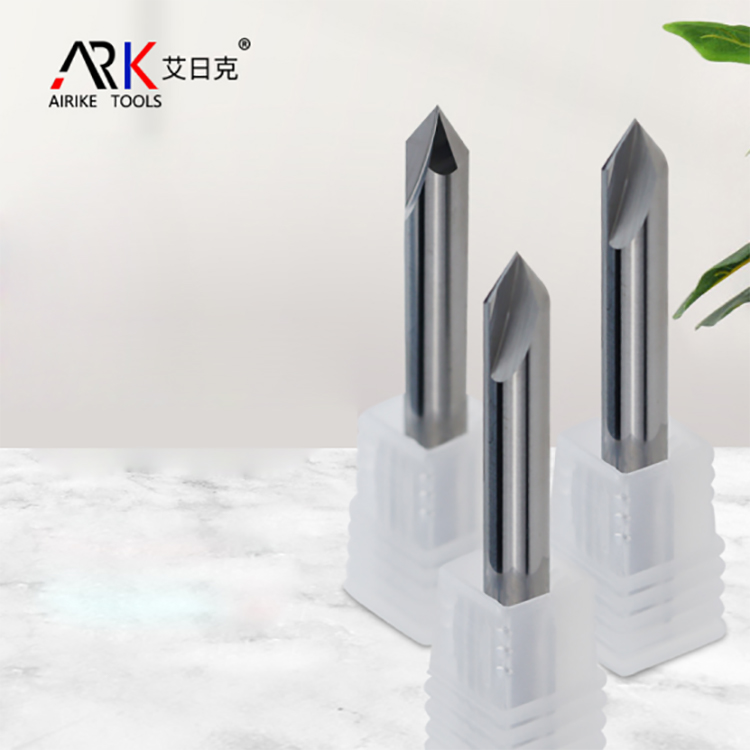

Second, the choice of cutting tool type

In the processing of carbon fiber materials, the commonly used types of cutting tools include PCD (polycrystalline diamond) tools and cemented carbide tools. pcd cutting tools are considered to be the best choice for processing carbon fiber materials due to their extremely high hardness and wear resistance. Compared with carbide tools, PCD tools can effectively reduce tool wear during the cutting process and improve machining efficiency and surface quality. In addition, PCD tools also have excellent thermal conductivity, can quickly emit the heat generated during the cutting process, to avoid tool damage and material deformation caused by high temperature.

Third, the importance of cutting tool geometry parameters

The geometric parameters of the cutting tool have a direct impact on the processing effect. In the selection of carbon fiber milling cutter, you need to pay special attention to the cutting tool edge angle, the number of edges and edge treatment. Generally speaking, a smaller cutting edge angle can reduce the cutting force and lower the risk of material delamination. At the same time, a smaller number of edges reduces the contact area between the tool and the workpiece, lowering the cutting temperature and thus reducing tool wear. In addition, the sharpness and smoothness of the cutting tool edge is also critical, and a sharp edge can effectively reduce cutting resistance and improve machining accuracy.

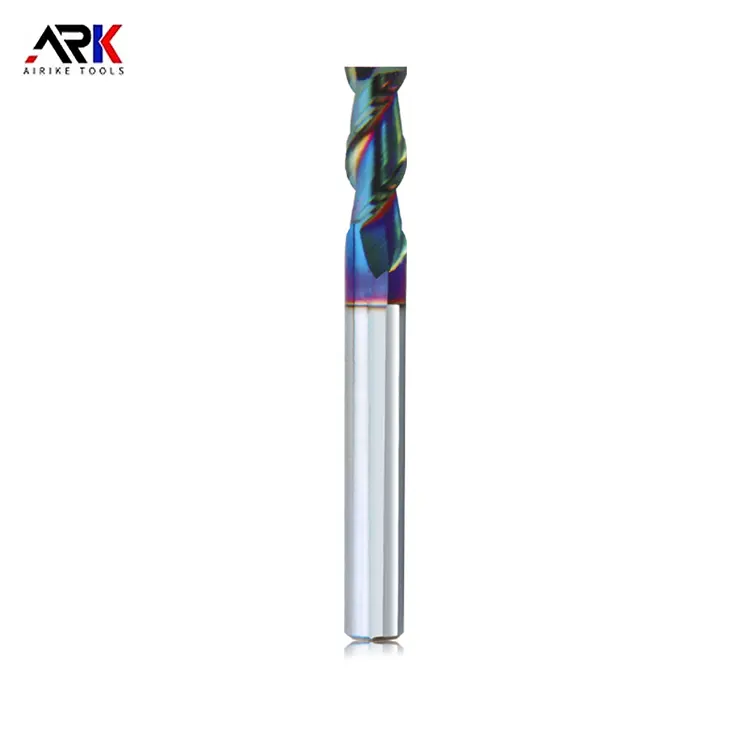

Fourth, the application of coating technology

Coating technology is an important means to improve the performance of carbon fiber milling cutter. Common cutting tool coatings include diamond coating, titanium nitride coating and aluminum titanium nitride coating. Diamond coating can significantly improve the hardness and wear resistance of the cutting tool, and extend the service life of the cutting tool. Titanium nitride coating and aluminum titanium nitride coating has good oxidation resistance and thermal conductivity, can effectively reduce the heat accumulation in the cutting process, to prevent the tool failure due to high temperature.3 In the selection of coatings, you need to choose the most suitable type of coating according to the specific machining conditions and material properties, in order to achieve good processing results.

Fifth, the impact of processing conditions

Machining conditions are factors that cannot be ignored when choosing a carbon fiber milling cutter. Cutting speed, feed and depth of cut and other parameters directly affect the processing performance and life of the cutting tool. In general, higher cutting speeds can improve machining efficiency, but will also increase the wear rate of the cutting tool. Therefore, when selecting cutting tools, cutting parameters need to be set reasonably according to specific machining requirements in order to balance machining efficiency and tool life. In addition, the temperature and humidity of the machining environment will also have an impact on the performance of the cutting tool, it is recommended that the machining be carried out in a constant temperature and dry environment to reduce the impact of environmental factors on the tool and workpiece.

Sixth, cutting tool cost and economic benefits

In the selection of carbon fiber milling cutter, the cost and economic benefits of cutting tool is also an important factor to consider. Although the initial cost of PCD tools and diamond-coated tools is higher, their excellent wear resistance and long life can significantly reduce the unit processing cost and improve economic efficiency. Therefore, when selecting cutting tools, it is necessary to comprehensively consider the initial cost, service life and machining efficiency of the tool, and select the most cost-effective type of tool to achieve the best economic benefits.

It can be seen from the above introduction that the selection of carbon fiber milling cutter is a comprehensive work, which needs to be considered comprehensively from a number of aspects, such as material properties, cutting tool type, geometric parameters, coating technology, processing conditions and economic benefits. Only by choosing the right cutting tool can we effectively improve processing quality and efficiency, extend tool life, and create greater economic benefits for the enterprise.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.