Email Us

Do you know what are the practical ways to reduce the cost of acrylic milling cutter processing?

Acrylic is widely used in advertising signs, decoration, electronic products and other fields by virtue of its transparent and beautiful, easy to process characteristics. However, milling processing, milling cutter wear faster, processing efficiency is not enough, scrap rate is high and other issues, easily lead to acrylic milling cutter overall cost rise. Want to reasonably control costs, need to optimize from the tool, process, equipment management and other aspects of integrated optimization, the specific methods of Zhongye Da editorial share the following:

First, optimize the tool selection and management

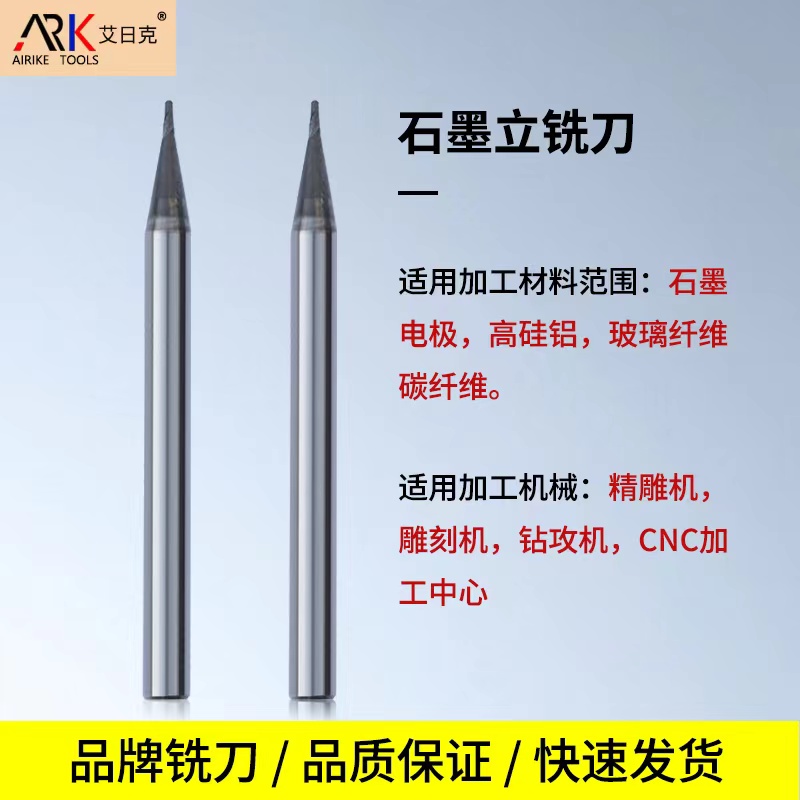

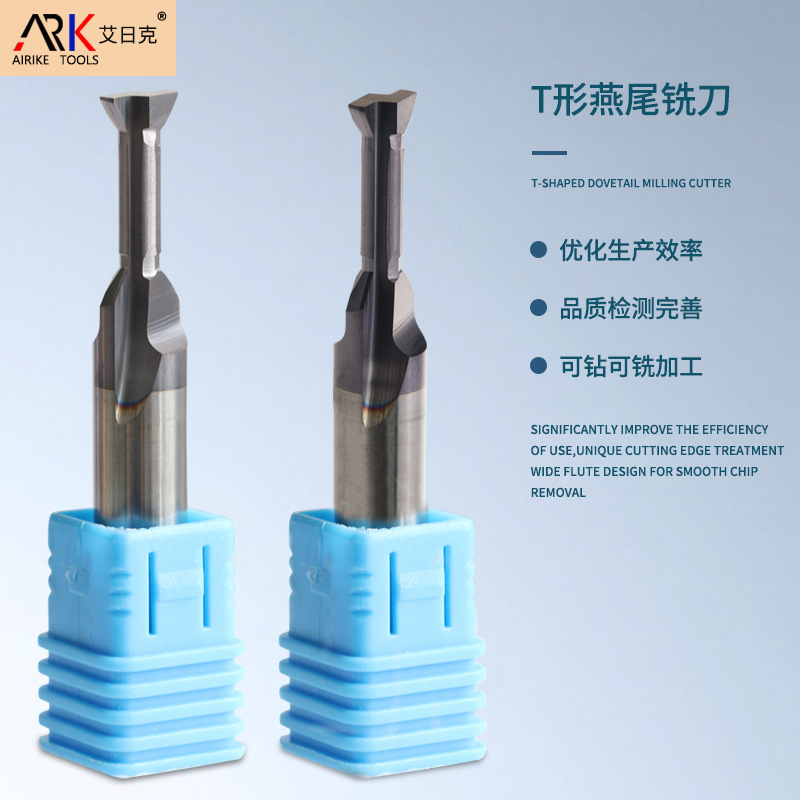

Selected specifically designed for plastics carbide milling cutter, wear resistance is better than high-speed steel cutting tools, although a single slightly more expensive, but the life is longer, and long-term replacement costs can be reduced. Consider single crystal diamond milling cutter for mass production. Priority selection of large helix angle, large front angle style, reduce cutting heat and scrap rate. Establishment of acrylic milling cutter tool management mechanism, record the length of use, timely replacement or sharpening, to avoid workpiece scrap.

Second, optimize the processing technology and parameters

Adopt high speed, fast feed, small depth of cut milling, reduce cutting force to prevent chipping, reduce friction heat to prevent material softening. With CAM software to optimize the acrylic milling cutter path, reduce the empty stroke and sharp turns, shorten the processing time. Cooling selection of air-cooled or oil mist, to avoid liquid coolant affecting acrylic.

Third, strengthen equipment maintenance and standardized operation

Stable equipment status is the basis for cost control. Regular maintenance of CNC machine tools to ensure that the spindle running without vibration, guide rail lubrication is good, for tool protection and machining accuracy to provide protection. Standardize the workpiece clamping process, the use of vacuum suction cups or special fixtures, to ensure that the workpiece is firmly fixed and uniform force, to avoid the displacement of the workpiece in the processing of tool damage or workpiece scrap.

Fourth, pay attention to waste recycling

Acrylic waste and trimmings have recycling value, the establishment of a classification and collection system, the waste will be centralized recycling and sold to professional recycling agencies, not only to create additional revenue, but also in line with environmental requirements, and indirectly reduce processing costs.

In short, to reduce the cost of acrylic milling cutter processing, need to combine tool optimization, process adjustment, equipment maintenance and waste recycling and other measures.

Zhongye da editorial think through a reasonable choice of tools, scientific setting of processing parameters, standardize the operating procedures, both to ensure the quality of processing, but also to reduce tool loss, reduce scrap rate, and ultimately realize the effective control of processing costs, while improving production efficiency.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.