Email Us

What is the welding process for Welded Milling Cutters?

Welded milling cutters secure carbide inserts to the cutter body through welding, forming an integrated structure. Combining rigidity with cost-effectiveness, they find significant applications across mechanical manufacturing, mold processing, automotive components, aerospace, and other fields. So, do you know how the welding process for welded milling cutters works? Below, Zhongye Da's editor will guide you through it!

I. Pre-welding Preparation

Inspect inserts for cracks or chipped edges. Ensure cutter slots match insert dimensions and are free of burrs or oil contamination. Clean inserts and slots with organic solvents like gasoline or alcohol. For mass production, enhance cleanliness through sandblasting or boiling in alkaline solutions.

II. Welding Methods and Material Selection

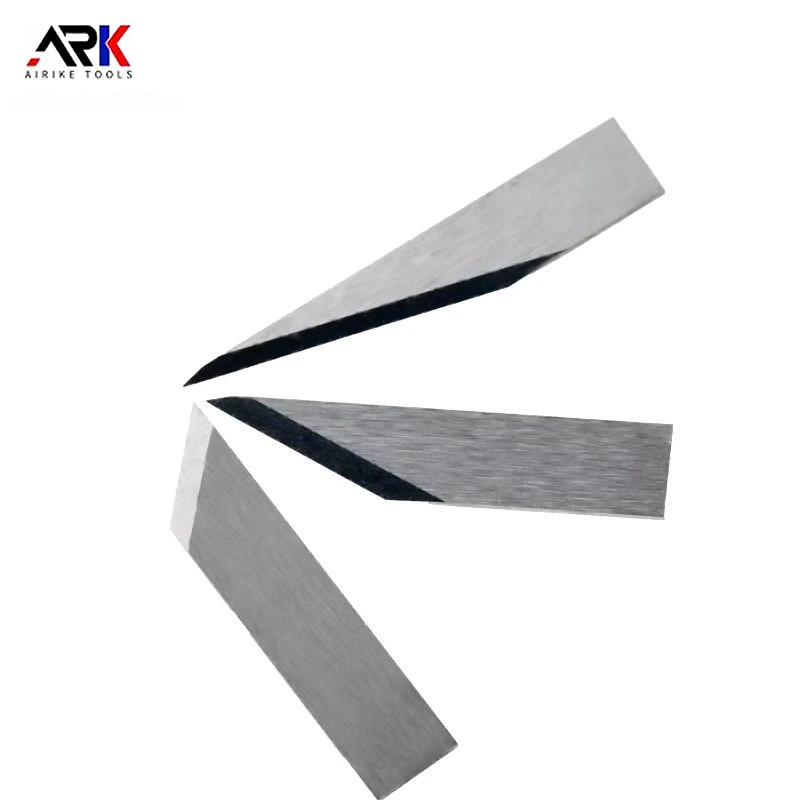

Common welding techniques for milling cutters include high-frequency induction brazing, gas flame brazing, and vacuum diffusion welding. High-frequency brazing is particularly suitable for mass production due to its high efficiency. Brazing filler metals typically use silver-based sheets with a silver content of no less than 35%. Flux primarily consists of industrial borax, which must be dehydrated before use. For fine-grained alloys with high titanium and low cobalt content or thin inserts, incorporate 0.2–0.5 mm mesh compensation pads to reduce welding stress.

III. Process Parameters and Operational Key Points

Control brazing temperature between 600–800°C. Optimize heating duration to avoid excessive speed or slowness. Secure the tool holder during welding. Sequentially place filler metal, flux, and blade. After uniform heating, once filler metal melts and flows out, gently nudge the blade to remove slag and align it before applying pressure until solidification. Alternate-tooth or diagonal welding may be used to reduce stress.

IV. Post-Welding Treatment

After welding, allow tools to cool naturally on the welding fixture for at least 2 hours before air cooling. Avoid rapid cooling. After cooling, remove residual flux and slag. For mass production, sandblast followed by boiling water treatment for 1-2 hours is recommended. Dry thoroughly before sharpening.

In summary, the welding process for milling cutters is a highly technical and meticulous task involving multiple stages. Strictly controlling the key points of each stage effectively enhances weld quality, extends the service life of welded milling cutters, and provides reliable assurance for machining operations.

-

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

- How to Choose Between PCD and MCD Tools?

- Your Essential Guide to Choosing the Perfect Engraving Machine Milling Cutter

- Which is better, graphite milling cutter or HSS milling cutter?

- Do you know what are the practical ways to reduce the cost of acrylic milling cutter processing?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.