Email Us

How to Improve the Processing Efficiency of Woodworking Milling Cutters?

In wood product manufacturing, milling is the core process for shaping designs and creating mortise-and-tenon joints. Processing efficiency directly impacts production costs, order fulfillment capabilities, and ultimately a company's market competitiveness. Many woodworking craftsmen and factory managers often ponder: How can we enhance milling cutter efficiency while maintaining or even improving processing quality? Below, Zhongyeda shares insights on this topic.

What Methods Enhance Woodworking Milling Cutter Efficiency?

I. Optimize Tool Selection and Condition

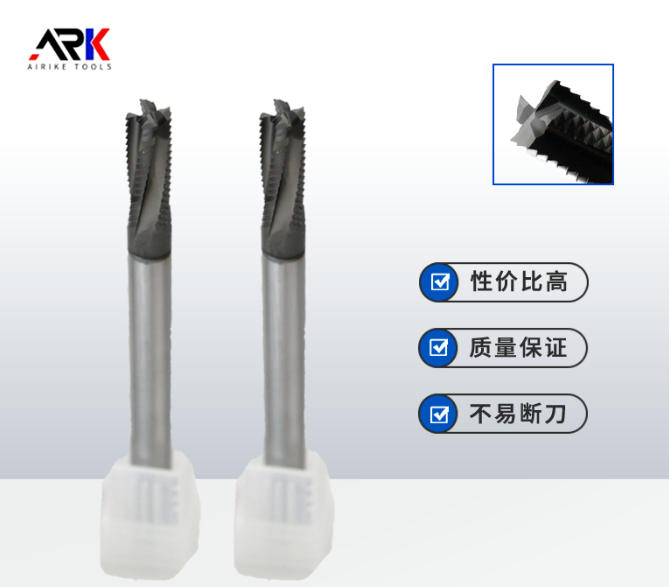

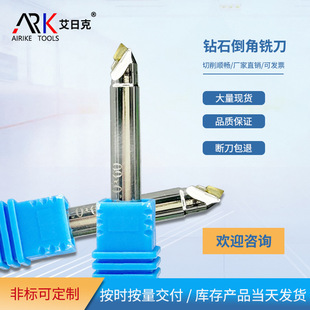

A craftsman must sharpen his tools to do his work well. The milling cutter itself is the most direct factor determining efficiency. First, select the most suitable tool type for the task at hand—use a slot cutter for slotting, a trimming cutter for edge finishing—rather than relying on one tool for multiple functions.

Second, maintaining sharp cutting edges is crucial. Dull tools are the primary efficiency killer—they increase cutting resistance, slow feed rates, cause wood tearing, and add post-processing time. Establish a routine for regular inspection and sharpening.

Additionally, selecting tools with non-stick coatings like Teflon effectively prevents resin adhesion, reduces friction, and ensures smoother cutting.

II. Optimizing Cutting Parameters and Techniques

Even with high-quality tools, scientific operation is essential to maximize performance. The core lies in balancing spindle speed and feed rate. While ensuring quality, strive to increase feed rates as much as possible to find the optimal balance between “high speed + high feed.” For workpieces requiring substantial material removal, employ layered cutting to avoid single-pass overcuts that may overload motors or damage tools.

Simultaneously, scientifically plan machining paths by prioritizing climb milling and minimizing idle travel time—both significantly reducing per-piece processing duration.

III. Ensuring Equipment and Auxiliary System Reliability

The efficient operation of woodworking cutters relies on stable equipment and robust auxiliary systems. Ensure the stability of the spindle and clamping system, regularly inspect spindle accuracy, and use high-quality tool holders to guarantee secure tool clamping and high concentricity, preventing processing errors caused by minor vibrations.

Additionally, a robust dust extraction system is indispensable. It promptly removes wood chips and dust, maintaining cleanliness in the work area and on the tools. This not only safeguards operator health but also creates essential conditions for sustained, efficient machining.

As outlined above, enhancing the machining efficiency of woodworking cutters is not achieved through isolated improvements in any single aspect. Rather, it results from the coordinated optimization of tools, operator techniques, and equipment. Starting with selecting a sharp, appropriately sized woodworking cutter, through matching scientific cutting parameters, to supplementing with stable equipment support—each step is intricately linked.

By integrating these methods into daily production practices, continuously experimenting and refining, you will not only witness a significant increase in processing speed but also experience a comprehensive leap in processing quality, cost control, and production management standards.

-

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

- How to Choose Between PCD and MCD Tools?

- Your Essential Guide to Choosing the Perfect Engraving Machine Milling Cutter

- Which is better, graphite milling cutter or HSS milling cutter?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.