Email Us

Your Essential Guide to Choosing the Perfect Engraving Machine Milling Cutter

How to Choose a Good Engraving Machine Milling Cutter

An engraving machine milling cutter is the finishing touch in digital manufacturing, a precision tool that transforms digital designs into exquisite physical objects. Choosing the wrong cutter can lead to damaged parts, project failures, wasted time, and accumulating frustration. However, if you understand its core principles and find the right partner, you can achieve unprecedented precision and efficiency, thereby transforming your work and ultimate profits.

The key to success: It starts with the cutting tip

Dull, mismatched, or inferior cutting tips can affect surface finish, detail reproduction, tool life, and even the lifespan of the machine. Therefore, whether you are carving intricate wooden signs, machining precision aluminum parts, or etching durable granite monuments, choosing the right engraving machine milling cutter is crucial.

Detailed introduction to commonly used engraving machine milling cutters:

| Core Engraving Machine Milling Cutter Types | Tip Geometry | Primary Strength | Common Applications |

|---|---|---|---|

| End Mills (Flat) | Flat, Square End | Sharp Corners, Fine Edges | Precise pockets/shoulders, clean edges, detailed lettering in softer materials where corners matter. |

| Ball Nose End Mills | Hemispherical (Rounded) | Smooth Contours | 2.5D & 3D contouring/molding, smooth bevels/scallops, artistic relief carving (wood/plastic/modelling board), general smoothing passes. Less precise corners but superb surface feel. |

| Tapered Ball Nose | Tapered Shank + Ball End | Deep Access | Deep, narrow crevices in complex 3D models (like miniature carving), decorative molds. Reaches where straight bits cannot without excessive tool deflection. |

| V-Bits / V-Groove Cutters | Angled Cone (e.g., 60°, 90°, 120°) | Sharp Veins, Deep Lines | Direct sign engraving (text, lines creating depth/shadow effect), decorative inlays, creating sharp chamfers/decorative grooves. The go-to bit for significantly raised, defined lettering without excessive Z-axis plunge steps. |

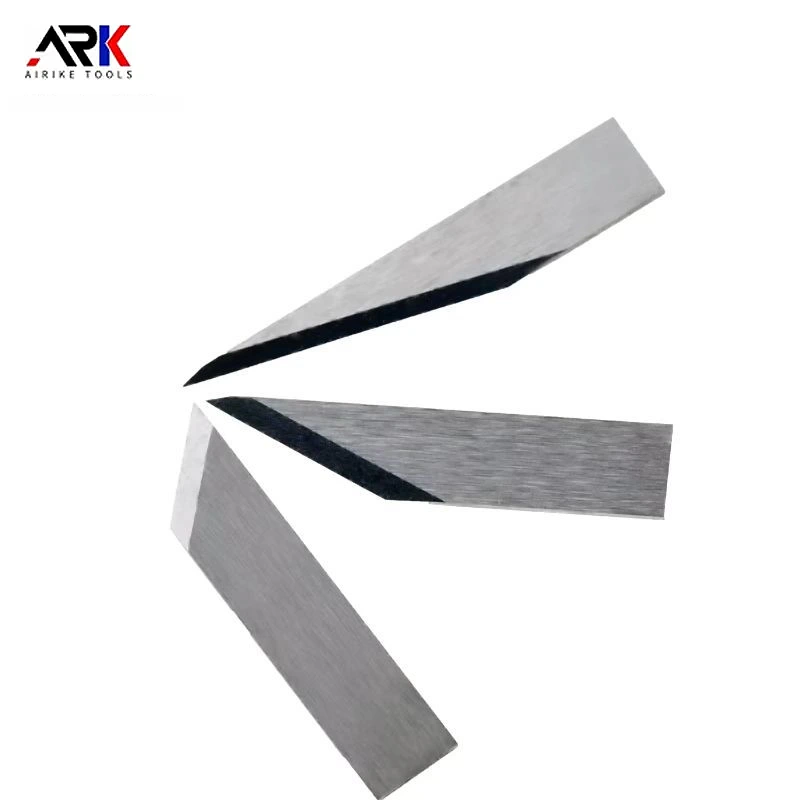

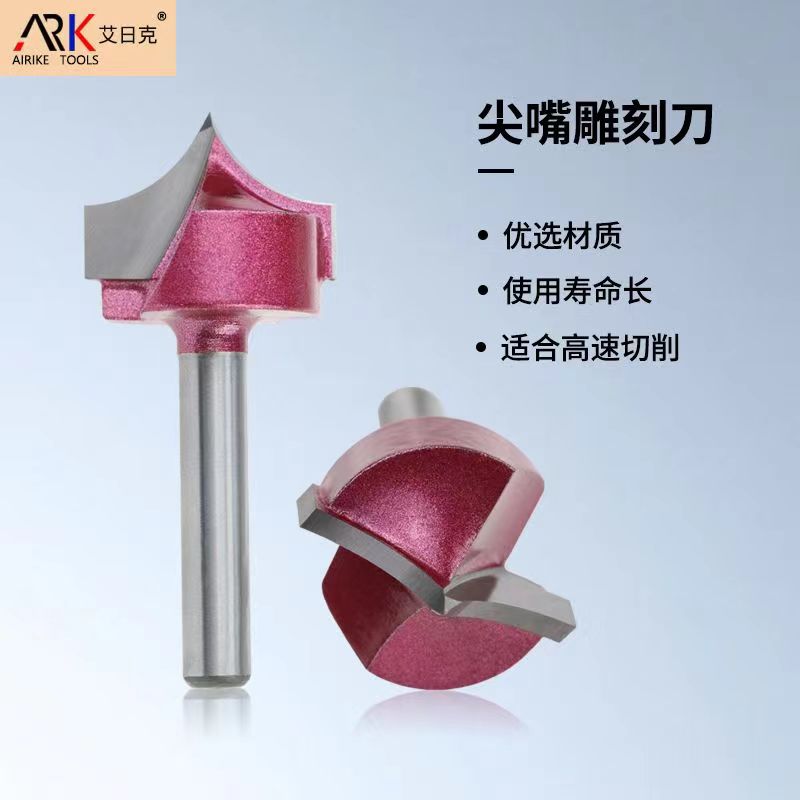

| Engraving Bits (Sharp Point) | Pointed Cone (V-Shape) | Ultra-Fine Detail / Etching | Extreme precision lettering and fine lines, surface etching (not removal depth) for logos, decoration, circuit boards (PCB isolation), acrylic surface marking. |

| Compression Spirals | Flats + Compression Fluting | Clean Top/Bottom Edges | Routing/Profiling sheet goods (plywood, MDF, plastics) without tear-out on top or bottom surfaces. Essential for clean letter cutting from sheet materials. |

| (Specialty) Diamond Drag Engravers | Diamond-Tipped Point | Surface Marking Hard Materials | Etching/marking glass, coated metals, stone surfaces without rotation. Low force required, excellent for logos/serialization on finished parts. |

Perfect Match Between Engraving Machine Milling Cutter and Workpiece

Understanding the interaction between the tool and specific materials can prevent material breakage and ensure perfect machining results.

1. Wood and Composite Material Machining:

Challenges: Wide range of hardness, diverse textures, knots, resin dulling of tools, and abrasives.

Key Tools: Compression helical end mills are essential for sheet metal machining; undercut helical end mills are used for fine surface finishes; ball end mills/tapered ball end mills are used for 3D engraving; overcut end mills are used for efficient roughing of solid wood; sharp V-cut end mills are used for fine text engraving.

Key Considerations: Consider the wood grain direction as much as possible. Always use sharp tools to avoid dulling exacerbating tearing and frictional heat. Carefully consider chip load, especially when machining composite materials containing abrasives. For very hard woods, lower speeds are often more effective.

2. Metal Machining:

Challenges: Work hardening, high heat generation, high toughness requirements for rigid geometry, and achieving smooth surfaces.

Main cutting tools: 2- or 3-flute end mills designed for aluminum or stainless steel; ball end mills for contouring; diamond drag cutters for surface marking.

Key considerations: Minimize heat, prevent work hardening, flush chips, extend tool life, and avoid using high-speed steel for batch metal engraving—it will dull quickly.

3. Stone and Glass Machining:

Challenges: Extremely abrasive properties require tools with a hardness exceeding that of the material itself, posing a risk of brittleness.

Main cutting tools: Diamond-coated carbide tools or solid diamond tips for stone/high-density ceramics; diamond drag cutters/diamond tips for glass or surface etching.

Key considerations: Continuous water supply is typically required to protect the diamond bond, suppress dust, and cool the tool. Diamond tips require frequent dressing to expose new material. The workpiece must be securely held to cushion the impact of vibrations on brittle materials.

Choosing the right tool geometry is crucial, but the other half lies in trusting the manufacturer of your engraving machine milling cutter. Zhongyeda's reputation is built on solving the core challenges engravers face daily:

1. High-performance materials as standard: From premium micron-sized carbide designed for impact resistance and extended sharpness to professionally bonded diamond coatings for wear resistance, our tools have a solid foundation from the outset for demanding tasks. This avoids the pitfalls common in inexpensive imported tools: rapid dulling, chipping under load, and batch-to-batch performance inconsistencies.

2. Carefully designed grooves: Whether it's a powerful upper cutter for wood cleaning, a clamping action for fine finishing, or balanced chip removal in industrial end mills for aluminum machining, effective chip removal prevents repeated cutting, overheating, and tool failure.

3. Optimized Diversity: From precision tools for jewelry engraving to robust spiral cutters for plywood signage, Zhongyeda understands a wide range of applications. We offer a comprehensive range of geometries (plain, ball, V-shaped, tapered) and flute designs to ensure you find the right tool for your specific material and desired machining results.

4. Durability: High-quality carbide means more cuts can be made before needing grinding or replacement, and excellent chip removal prevents secondary wear. This inherent toughness, combined with the possibility of specialized grinding, significantly reduces the cost per part and minimizes production downtime.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.