Email Us

The types and uses of Woodworking Milling Cutter

With the popularization of numerical control technology and the growth of customized demands, milling cutters have evolved from single cutting tools into comprehensive solutions that combine functionality, efficiency and creativity. As a core tool in modern woodworking craftsmanship, the diverse designs of woodworking milling cutters reflect a profound understanding of the characteristics of wood and a precise match with processing requirements. So, how much do people know about the types and uses of woodworking milling cutters? Now, let's take a look together with the editor of Zhongyeda!

I. Common types

1. Youdaoplaceholder0 straight knife type

Youdaoplaceholder0 basic straight tool : suitable for processing various slot widths, common specifications are 1/4 inch and 1/2 inch. Through multiple milling passes, the slot width within the range of 1/4 inch to 1/2 inch can be covered, meeting the basic processing scenarios such as tenons and mortises.

Youdaoplaceholder0 Bottom cleaning knife : based on the straight knife, it adds a lower cutting edge design and is suitable for processing closed grooves. Due to the limitation of the cutting depth, it is usually necessary to use an electric drill to complete the deep groove processing, and it can also replace an electric planer for the surface leveling treatment of wood.

2. Youdaoplaceholder0 trimming class

Youdaoplaceholder0 trimming tool : It achieves straight or curved trimming through bearing guidance and is suitable for edge trimming of workpieces.

Youdaoplaceholder0 profiling trimming tool : The bearing is located on the side of the tool holder and can be used in conjunction with the template for batch replication of irregular-shaped workpieces, thereby enhancing processing efficiency.

Youdaoplaceholder0

3. Rounded corner knife

It is equipped with bottom bearings to support handheld or upside-down engraving machine operation. Common specifications include 1/4 inch and 3/8 inch, and can be extended to the range of 1/8 inch to 3/4 inch. They are suitable for edge fillet processing of workpieces, curve engraving and rough machining of cylinders.

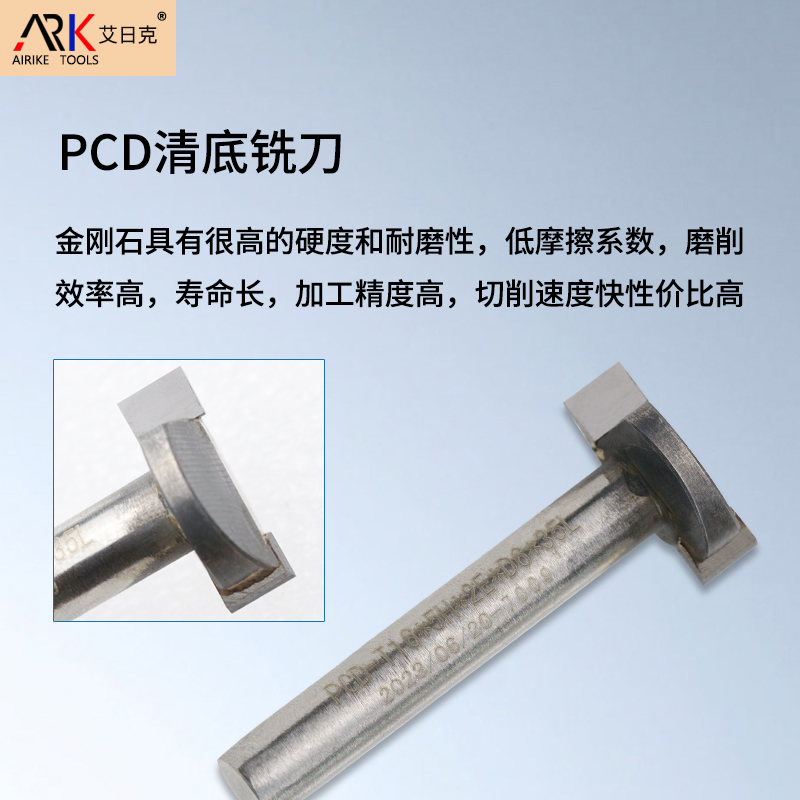

4. Youdaoplaceholder0 slot knife (T-shaped knife)

Specifically designed for the processing of side slots or T-slots, it simplifies the processing flow of complex slot types and enhances processing accuracy and efficiency.

II.Specific purpose

1. Furniture manufacturing

Straight knife: Complete the processing of connecting structures such as tenons and mortises.

Edge trimming knife: Achieve fine trimming of furniture component edges.

Rounding knife: used for arc treatment of table corners, chair backs, and other parts.

Slot knife: Processing drawer guide rails, back panel card slots and other structures.

2. Decoration and Renovation

Imitation trimming knife: Cooperate with templates to achieve batch replication of decorative lines.

Rounding knife: completes the arc processing of door and window frame lines, skirting lines and other parts.

Bottom cleaning knife: used for flat processing of wooden floor splicing grooves, wall panel card grooves, etc.

3. Woodcraft carving

Straight knife: Complete basic contour carving.

Rounded corner knife: realizes surface carving and detail decoration.

Spiral straight knife: improves chip removal efficiency through spiral blade design, suitable for complex working conditions such as deep grooves and irregular carving.

That's all for the types and uses of woodworking milling cutters mentioned above. I hope this article is helpful to everyone. If there is anything else you don't understand, you can leave a message for us and we will answer it as soon as possible.

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

- Did you use the milling cutter straight out of the box? How come it chipped in just half an hour?

- Acrylic Milling Cutter Not Spinning? Quick Troubleshooting Guide

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.