Email Us

Performance advantages of PCD tools

Performance advantages of PCD tools

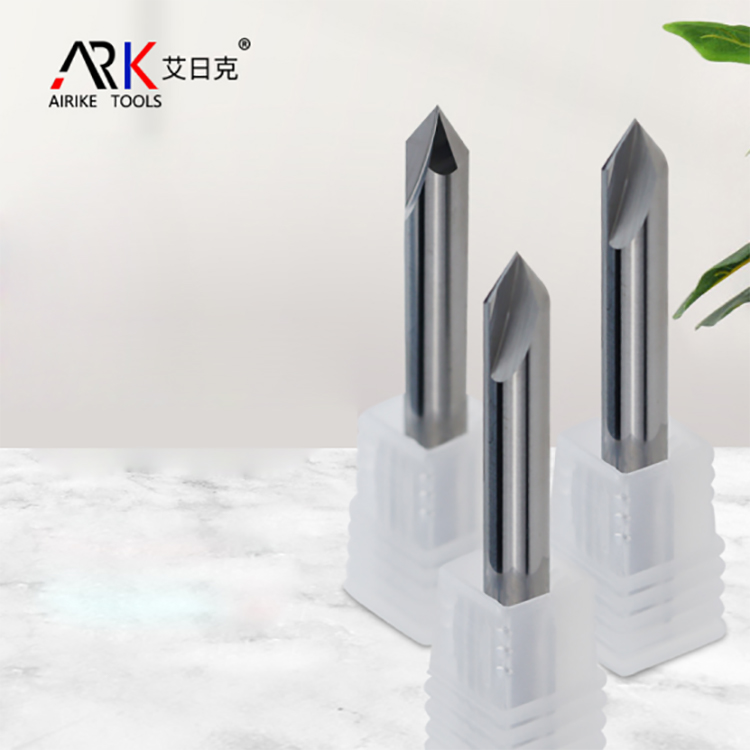

PCD tools are made of superhard material PCD (polycrystalline diamond) and tool matrix through special process. They have the characteristics of high hardness, high compressive strength, good thermal conductivity, good wear resistance, etc. So how much do you know about the performance advantages of PCD tools? The following editor of Zhongyeda will take you to understand.

The performance advantages of PCD tools are as follows:

1. The hardness of PCD can reach 8000HV, which is 80-120 times that of cemented carbide;

2. The thermal conductivity of PCD is 700W/mk, which is 1.5-9 times that of cemented carbide, even higher than PCBN and copper, so PCD tools transfer heat quickly;

3. The friction coefficient of PCD is generally only 0.1-0.3 (the friction coefficient of cemented carbide is 0.4-1), so PCD tools can significantly reduce cutting force;

4. The thermal expansion coefficient of PCD is only 0.9×10-6-1.18×10-6, which is only 1/5 of that of cemented carbide, so PCD tools have small thermal deformation and high processing accuracy;

5. The affinity between PCD tools and non-ferrous metals and non-metallic materials is very small, and chips are not easy to stick to the tool tip to form built-up edge during processing.

To sum up, these are the performance advantages of PCD tools. Because PCD tools have high hardness, high heat resistance, long life, sharp chip edges and good thermal conductivity, they can meet the requirements of automotive parts processing for high speed, high efficiency, high precision, new materials and new shapes, so PCD tools will surely be used more and more widely.

- How to Choose Chamfering Cutter Brands? Three Steps to Find the Right Fit

- What are the parameters for graphite milling cutters?

- Is a spiral or straight flute woodworking milling cutter better for edge trimming?

- Can diamond-tipped Engraving Machine Milling Cutters handle ultra-fine detail engraving?

- How to Improve the Processing Efficiency of Woodworking Milling Cutters?

- What is the welding process for Welded Milling Cutters?

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.