Email Us

Products

Buy single-edge milling cutter, single-edge combination cutter, tct cutting milling cutter from Zhongyeda. High quality, great select and expert advice are our characteristics. You can rest assured to buy the products from our factory and we will offer you good after-sale service and timely delivery.

- View as

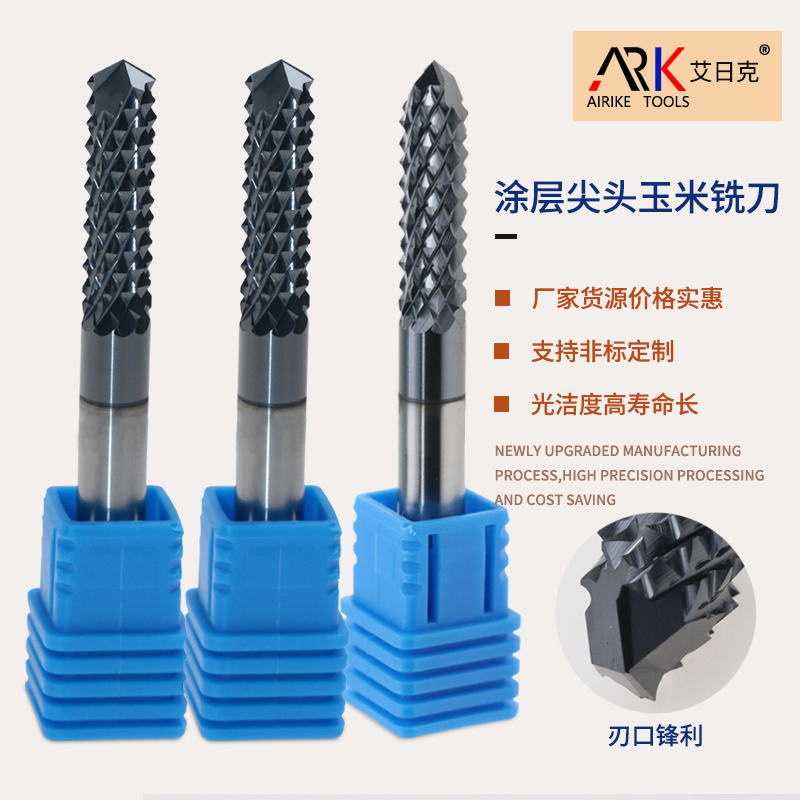

Coarse-Skinned Corn Milling Cutter Tip

Zhongyeda as a professional high quality Coarse-Skinned Corn Milling Cutter Tip manufacture, you can rest assured to buy Coarse-Skinned Corn Milling Cutter Tip from our factory and we will offer you the best after-sale service and timely delivery.

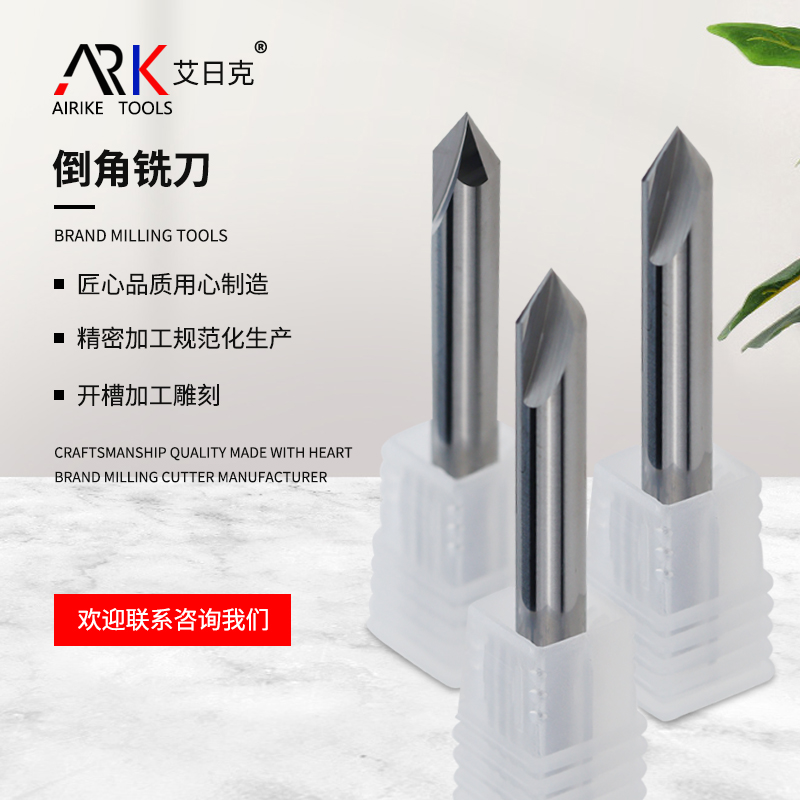

Composite Material Milling Cutter

Zhongyeda as the professional manufacture, we would like to provide you Composite Material Milling Cutter. And we will offer you the best after-sale service and timely delivery.

Flat Bottom Corn Milling Cutter

Zhongyeda as the professional manufacture, we would like to provide you high quality Flat Bottom Corn Milling Cutter. And we will offer you the best after-sale service and timely delivery.

Bakelite Milling Cutter

You can rest assured to buy Bakelite Milling Cutter from Zhongyeda factory and we will offer you the best after-sale service and timely delivery.

Corn Milling Cutter Left

Zhongyeda is a professional China Corn Milling Cutter Left manufacturer and supplier, if you are looking for the best Corn Milling Cutter Left with low price, consult us now!

Integral Alloy T-Type Cutter

In response to the needs of high-precision machining and heavy-duty cutting, Zhongyeda's high-quality integral alloy T-type cutter reshapes the milling standard with an integrated design. The cutter bar and cutter head are integrally sintered with ultra-fine tungsten steel (YG10X), with a hardness of HRA92 and a bending strength of 4800MPa, completely eliminating the risk of welded cutters falling off. It is specially designed for difficult-to-process materials such as mold steel, titanium alloy, and high-temperature alloy.

Contact Us

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

Copyright © 2025 Shenzhen Zhongyeda Precision Technology Co., Ltd. All Rights Reserved.